Audited Supplier

Audited Supplier

In This Store

Category:API Equipment > Drying Equipment

Product Name:Stainless steel Flash Dryer TaYaCn Drying

Price(USD):Negotiable

Company:JIANGSU TAYACN DRYING TECHNOLOGY CO.,LTD

Factory Location: Jiaoxi Industrial Development Zone, Zhenglu Town, Changzhou City, Jiangsu Province, China

Main Sales Markets: North America,Australasia,Asia,Middle East

Delivery Lead Time: 45

Sample Provided: no

Payment Terms: L/C

Working principle The

hot air tangent enters the bottom of the dryer and is driven by a stirrer to create a powerful rotating wind field. The paste material enters into the dryer through the screw feeder. Under the strong action of the high-speed rotating paddle, the material is dispersed under the action of impact, friction and shear force. The bulk material is quickly crushed and fully contacted with hot air and heated. ,dry. The dehydrated dry material rises with the hot gas flow. The grading ring retains large particles. The small particles exit the dryer from the center of the ring and are recovered by the cyclone separator and the dust collector. It is not dried or the bulk material is affected by the centrifugal force. And falling back to the bottom was crushed and dried.

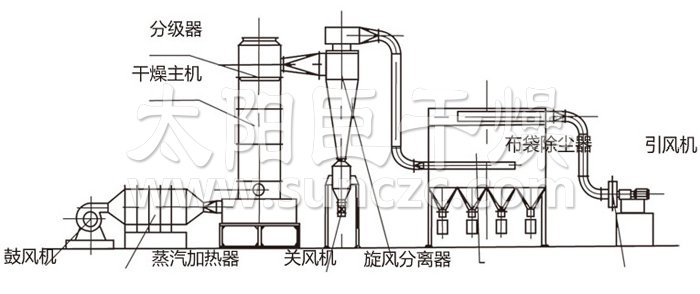

Schematic

Performance characteristics

◎ organic combination of swirling, fluidization, spouting and crushing and grading technology.

◎ Compact equipment, small size, high production efficiency, continuous production, and realization of "small equipment, large-scale production."

◎ Large drying strength, low energy consumption, high thermal efficiency.

◎ Short material residence time, good quality of finished product, can be used for heat-sensitive material drying.

◎ negative pressure or micro-negative pressure operation, good sealing, high efficiency, eliminate environmental pollution.

Adaptable materials

Organics: Atrazine (pesticides), lauric acid, benzoic acid, benzoic acid, bactericide, sodium oxalate, cellulose acetate, organic pigments.

Dyes: Antimony, black iron oxide, indigo pigment, butyric acid, titanium hydroxide, zinc sulfide, various azo dye intermediates.

Inorganic materials: borax, calcium carbonate, hydroxide, copper sulfate, iron oxide, barium carbonate, antimony trioxide, various metal hydroxides, various heavy metal salts, synthetic cryolite, and the like.

Food: Soy protein, gelatinized starch, wine chute, wheat sugar, wheat starch, etc.

Technical specifications

| model | XSG-2 | XSG-4 | XSG-6 | XSG-8 | XSG-10 | XSG-12 | XSG-16 | XSG-20 |

| Host internal diameter mm | 200 | 400 | 600 | 800 | 1,000 | 1200 | 1600 | 2000 |

| Air volume M 3 /h | 350-500 | 1150-2000 | 2450-4500 | 4450-7550 | 7000-12500 | 10000-20000 | 18000-36000 | 28200-56500 |

| Evaporation water kg/h | 12-17 | 40-70 | 80-150 | 150-250 | 230-4250 | 300-600 | 600-1000 | 1000-1500 |

| Maximum installed capacity kw | 10 | 20 | 40 | 65 | 85 | 105 | 150 | 230 |

| Maximum height m | 4.0 | 4.8 | 5.8 | 6.5 | 7.1 | 7.8 | 8.8 | 10.1 |

| Land area m 2 | 15 | 20 | 28 | 35 | 40 | 52 | 80 | 150 |

Note: 1. Moisture evaporation is the amount of water evaporated per hour when the inlet air temperature is 1 80 o C, and the outlet air temperature is 80 o C.

2. Special designs can be made for users except the above models.

3. Installation above The capacity is standard and can be significantly reduced depending on the power of different materials.

Processing materials and characteristics (based on type 6 flash evaporation)

| Material name | Stearic acid | Aluminum hydroxide | Zinc carbonate | Insecticide list | TMTD | DSD acid | Iron oxide red | Strontium dioxide | Cuprous chloride | White carbon black |

| Inlet air temperature o C | 150 | 180 | 150 | 120 | 140 | 150 | 200 | 180 | 200 | 280 |

| Initial moisture content% | 80 | 55 | 80 | 30 | 65 | 60 | 60 | 45 | 30 | 85 |

| Final moisture content% | 0.5 | 1.5 | 1.0 | 1.0 | 0.5 | 0.5 | 0.5 | 1.0 | 3.0 | 5.0 |

| Actual drying capacity kg/h | 140-160 | 250-280 | 130-170 | 80-110 | 80-120 | 80-120 | 300-350 | 280-320 | 290-310 | 250-300 |

| Material name | Accelerator | Oil soluble ink | Manganese zinc oxide | Yan Qinglan | Calcium Citrate | Ultrafine calcium carbonate | Slurry treatment agent | Sodium dioxyisocyanurate | Sodium trioxyisocyanurate |

| Inlet air temperature oC | 150 | 150 | 120 | 150 | 140 | 160 | 200 | 180 | 150 |

| Initial moisture content% | 60 | 45 | 30 | 55 | 40 | 70 | 75 | 25 | 30 |

| Final moisture content% | 0.5 | 2.0 | 1.0 | 1.0 | 1.0 | 1.5 | 5.0 | 0.2-2 | 1.0 |

| Actual drying capacity kg/h | 80-110 | 350-380 | 120-150 | 160-180 | 300-350 | 430-470 | 290-310 | 80-120 | 90-150 |

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025