Audited Supplier

Audited Supplier

In This Store

Category:Cleanroom System > Cleanroom

Product Name:PPGI/Ss Steel/HPL /PU/Rock Wool/EPS Customized Modular Cleanroom Sandwich Panel for Pharmaceutical

Price(USD):USD40-90 per meter squre

Company:QINGDAO WISE LINK INTERNATIONAL CO.,LTD

Factory Location: Shandong Province, China

Main Sales Markets: North America,Central/South America,Western Europe,Eastern Europe,Australasia,Asia,Middle East,Africa

Packaging Information: standard exporting packing

Delivery Lead Time: 1 month

Sample Provided: no

Payment Terms: T/T

Product Description

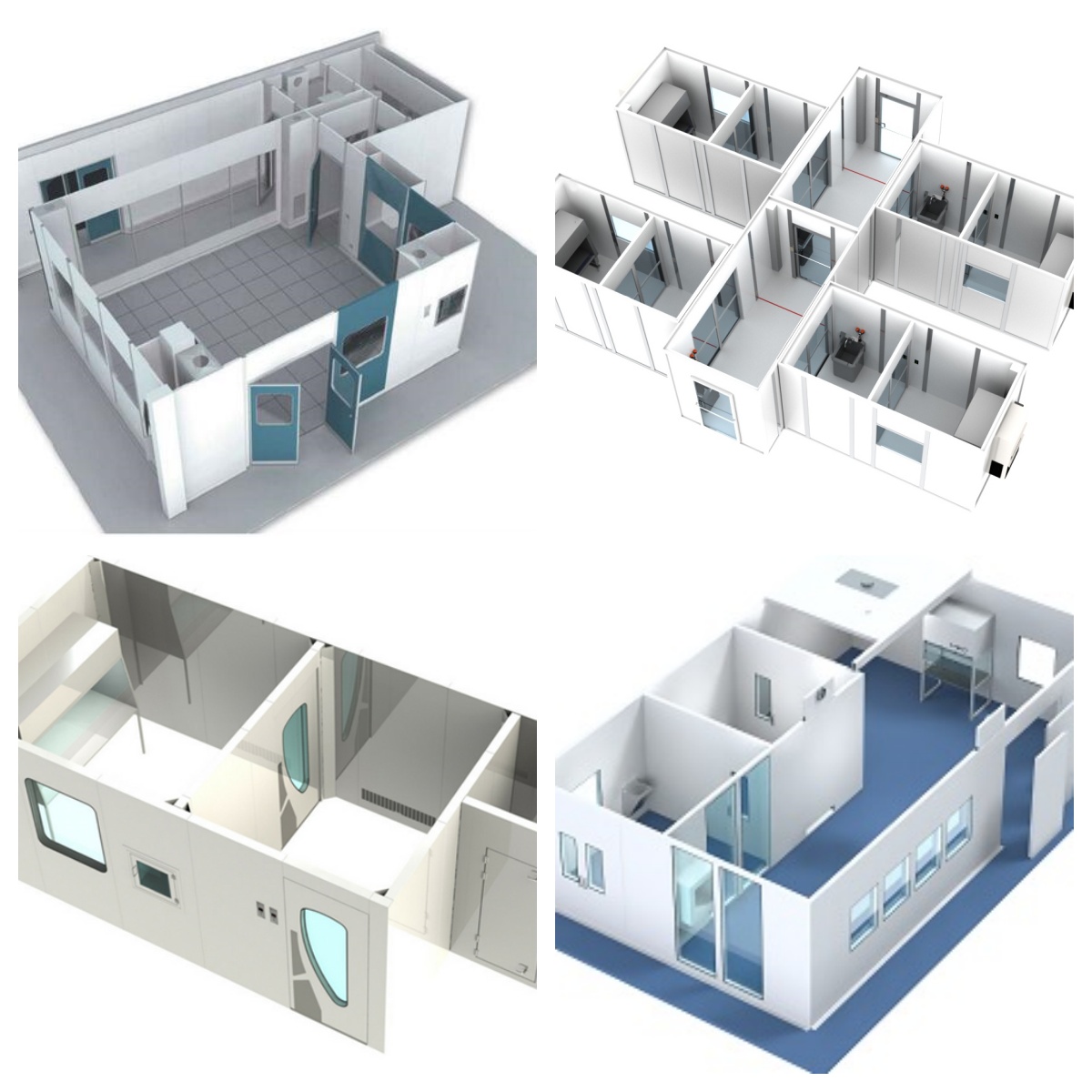

The development of clean rooms is closely linked to modern industry and cutting-edge technology. Due to the environmental requirements of the precision machinery industry (such as gyroscopes, miniature bearings, etc.), the semiconductor industry (such as the production of large-scale integrated circuits), etc., the development of clean room technology has been promoted.

A clean room is a space that can be used for human activities when the air cleanliness reaches a specified level. Its function is to control the contamination of particulates (dust particles). To meet the production of precision products and scientific experiment activities. The clean room is by no means limited to "clean", different industries and departments have considerable requirements for temperature, temperature, lighting, noise, static electricity, micro-vibration multi-functional comprehensive whole, is a set of building decoration (closed decoration with the atmosphere relatively isolated), purification of air conditioning, pure water, pure gas, power electricity, lighting electricity, process pipeline and other professional and technical products.

Product Parameters

| Width | 980mm |

| Max Length | 7500mm |

| Wall TCK | 50mm |

| Steel Thickness | 0.4-0.8mm |

| Outer plate material | PPGI,Al-mg-Mn Alloy steel,SS steel,Ti-Zn steel,HPL,VCM |

| Coating | PE,PVDF,HDP |

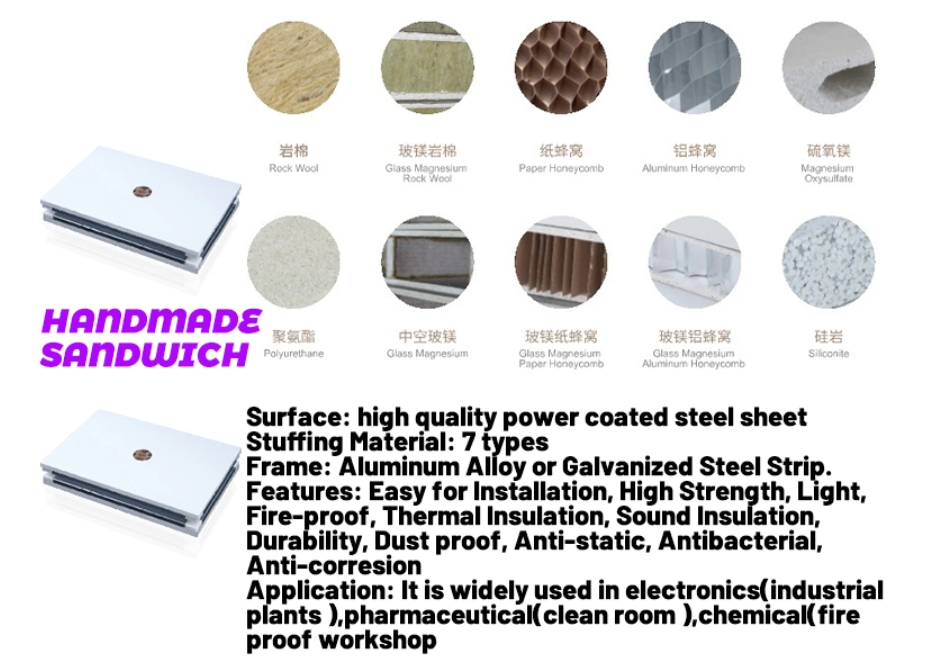

| Core material | PU,rock wool,magnesium board,paper honeycomb,aluminium honeycomb,plaster,EPS, etc. |

| Frame Thickness | 0.6-0.8mm |

| Application | Pharmaceutical Clean Room, Electronic Clean Room, Food Clean Room, etc. |

|

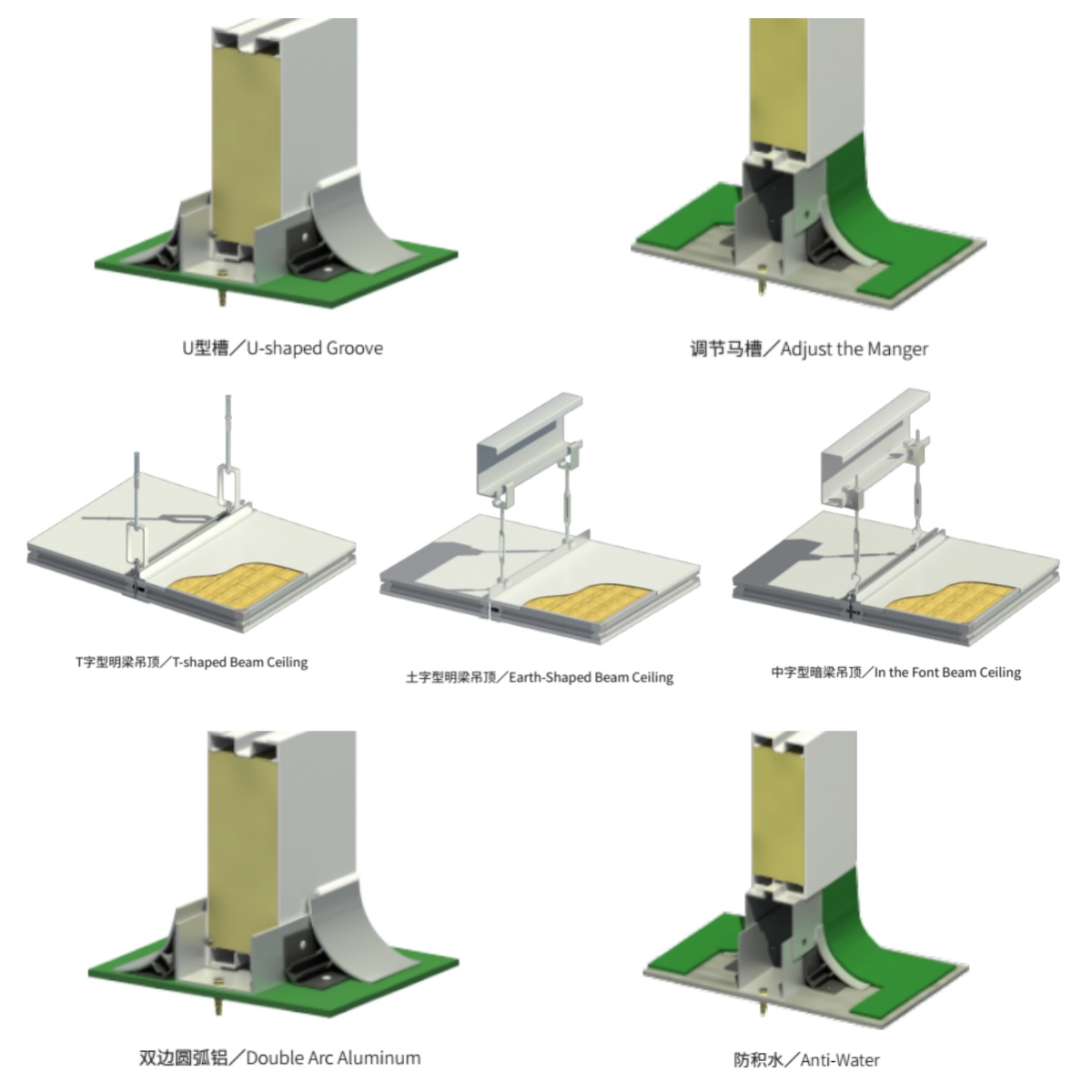

Wall Panel |

Thickness - 50mm, double color painted hot-dipping galvanized steel sheet, 0.5mm thick PE coated steel sheet, 0,8mm thick GI |

|

Wall Panel accessories |

Aluminum joint profiles |

|

Top track (aluminum slot), 30*50*30mm |

|

|

Adjustable floor track |

|

|

Straight corners |

|

|

R50 round corner inside |

|

|

3-way connector inside (per pc) |

|

|

middle type 3-way connector outside |

|

|

door seal (per pair) |

|

|

Ceiling panels |

Thickness - 50mm, double layer color painted hot-dipping galvanized steel sheet, 0.5mm thick PE coated steel sheet, 0.8mm thick GI |

|

Ceiling Panel accessories |

Aluminum joint profiles |

|

Aluminum Grid |

|

|

Hanging bar, with expansion bolts, T screw, square regulator, connector, nuts |

|

|

Clean room Doors |

Steel doors: 50mm thickness; 1.0 mm double-side electro galvanized steel sheet, with paper honeycomb inside; Including 50mm thick |

|

Single leaf, size 1000*2100mm |

|

|

Double leaf, size 1900*2100mm |

|

|

Door Closer, Brand: GEZE 1000C |

|

|

Interlock |

Electronic interlock to control two or more doors, with electromagnetic lock, light Indicator and main control box |

|

2 Doors |

|

|

Windows |

Double tempered glass view window, joints filled with silicon sealant, with vapor absorption, 5mm thick glass |

|

Size: 1200*1000*50mm |

|

|

Size: 1500*1000*50mm |

|

|

Silicone |

Dow corning silicone |

|

PVC conduits |

PVC conduit (25mm) inside wall panels |

|

Opening cost |

Openings in ceiling/wall panels |

| Effective width | Wall panel: 950mm 1150mm Ceiling panel: 950mm |

| Length | According to customer's request(less than 7500mm) |

| Core Materials | PU/Rock Wool/Glass Magnesium |

| Structure | Upper and lower layer: Color steel sheet |

| Middle: PU/Rock Wool/Glass Magnesium | |

| Thickness | Color steel sheet: 0.3-0.8mm Rock wool: 50mm 75mm 100mm |

| The Density of Rock Wool | 40kg/m3 -120kg/m3 |

| Color | RAL Standard |

| Character | Fireproof, heat insulation, sound proof, green and environmental friendly |

| Use | pharmaceutical & electronic clean rooms, hospital operating rooms, food processing factories, offices, etc. |

The different's cores

Clean room Introduction:

Cleanrooms are essential to any manufacturing process where particulate contamination can affect the quality of goods produced.

Specific clean room classifications and ISO class code descriptions provide protective guidelines and secure environments

through controlled air filtration, which lowers the possibility of product contamination or large particulate interference within

critical process manufacturing. Specific cleanroom requirements and ISO 14644-1 cleanroom standards are used to protect

consumers from any potential flaw or mishandling of a product.

|

Clean rank of suspended particles in air of clean room or clean area |

|||||||

|

ISO rank for air cleanness |

Bigger or equal to maximum concentration limits in table (P/m3-air) |

||||||

|

0.1um |

0.2um |

0.3um |

0.5um |

1um |

5um |

American federal 209E rank for cleanness |

|

|

ISOClass1 |

|

|

|

|

|

|

|

|

ISOClass2 |

100 |

24 |

10 |

4 |

|

|

|

|

ISOClass3 |

1000 |

237 |

102 |

35 |

8 |

|

1 |

|

ISOClass4 |

10000 |

2370 |

1020 |

352 |

83 |

|

10 |

|

ISOClass5 |

100000 |

23700 |

10200 |

3520 |

832 |

29 |

100 |

|

ISOClass6 |

1000000 |

237000 |

102000 |

35200 |

8320 |

293 |

1000 |

|

ISOClass7 |

|

|

|

352000 |

83200 |

2930 |

10000 |

|

ISOClass8 |

|

|

|

3520000 |

832000 |

29300 |

100000 |

|

ISOClass9 |

|

|

|

35200000 |

8320000 |

293000 |

300000 |

Clean room Door

Cleanroom door is used in all levels of cleanrooms, purified rooms, dust free rooms, sterile rooms, movable rooms and places where sandwich panels are used as partitions. The surroundings are double-sealed, heat-preserving and heat-insulating. Sandwich panels or stainless steel panels can be used to customize cleanroom doors of different specifications; the door locks, colors, sweeping strips can be configured as required.

Classification: Swing Door (Single Door, Double Door, unique Door, Glass Door), Electric Sliding Door, Fast Rolling Door

Classified by different materials: sandwich panel door, steel door, melamine resin door, stainless steel door

The door and the wall panel are connected evenly on both sides, all corners use arc transitions, sanitary lifting hinges, push-type door locks, and automatic sealing strips.

Door lock and hinge: The structure and design can achieve a smooth connection on both sides, and the door lock system should avoid hand contact pollution.

Automatic lifting sealing strip at the bottom of the door: three sides of the door frame should use sealing tape and automatic lifting sealing strip at the bottom of the door to ensure the air tightness of the door system.

Electronic interconnection lock classification: electric plug interconnection lock, electromagnetic interconnection lock, cathode interconnection lock

Clean door thickness 50 mm, face panel can be stainless steel plate, color coating, cold plate baking paint.

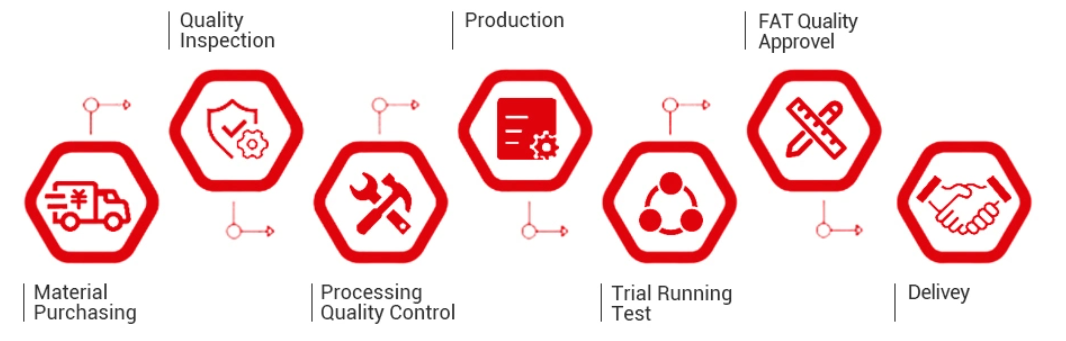

Installation Instructions

Our Advantages

Advantage:

Projects fotos

FAQ

1.Are you a Factory/Manufacturer or Trading Company?

We are a manufacturer with 15 years experience of production and have a modern standard plant of 100000 m².

2.How about your lead time?

It will take 3-7 days for budget and design according to the drawings after receiving the deposit. 15-30 days if there are some special sizes.

3.How about your core competitiveness?

We have the first automatic production line in the world. Compared with the traditional manual production line, the production efficiency increased by 6-8 times, leading most competitors. That means lower cost and higher quality.

4.Do you have your own construction team?

No, but all of our cleanroom panels and connected parts are easy for disassemble and installation due to our excellent design. What's more, we provided the instruction and videos for installation and we can send our professional superviors to the site.

5.How many kinds products do you have?

At present, we have more than 30 different products, including clean room wall panel system, ceiling system, clean room door, clean room window and so on.

6.Can you provide samples? Is it free or extra?

Yes, we can provide samples for free, but we would appreciate it if freight to collect.

7.What is your terms of payment ?

30% T/T prepay, 70% T/T before delivery. We can discuss payment if we have more cooperation in the future.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025