Twelve years of qualification

Twelve years of qualification

Audited Supplier

Audited Supplier

In This Store

Category:Preparation Equipment > Deeding Device > Lifting Charging Machine

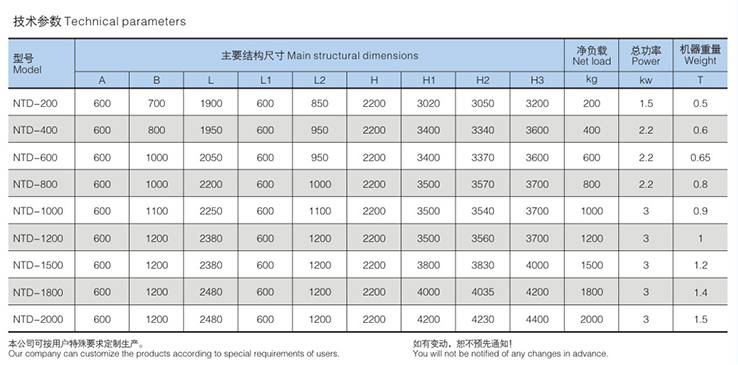

Product Name:NTD HOPPER LIFTING CHARGING MACHINE

Price(USD):15000US$-30000US$

Company:Jiangyin Snynxn Granulating Drying Equipment Co.,Ltd

Factory Location: Jiangyin city,Jiangsu,China

Main Sales Markets: North America,Central/South America,Western Europe,Eastern Europe,Australasia,Asia,Middle East,Africa

Monthly Production Capacity: 1

Contract Manufacturing: CMO

Packaging Information: Export wooden box

Delivery Lead Time: 2-3months

Sample Provided: no

Payment Terms: T/T

Purpose

This machine is mainly used for conveying and feeding solid materials in pharmaceutical industry. It can be used with mixer, tablet press, capsule filling machine and other equipment. At the same time, it is widely used in pharmaceutical, chemical, food and other industries.

Principle

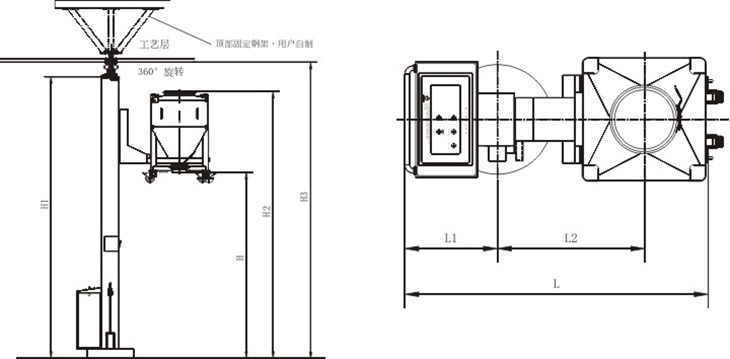

The machine is mainly composed of chassis, column, lifting system and other components. When working, first push the hopper containing materials onto the fork frame of the hopper elevator, then start the lifting button, and the hopper will lift. After the hopper is in place, rotate the chassis to connect with the feeding equipment in a closed manner, and open the discharge butterfly valve to transfer the materials to the next process in a closed manner.

Characteristic:

This machine is a new model that our company has widely absorbed and digested foreign advanced technology and successfully developed in combination with national conditions. The structure is reasonable, the performance is stable, and the operation is convenient. The whole machine has no dead corners and no exposed screws. The machine is easy to clean, effectively controls dust and cross contamination, optimizes the production process, and fully meets the GMP requirements of drug production.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025