Four years of qualification

Four years of qualification

Audited Supplier

Audited Supplier

In This Store

Category:API Equipment > Extraction Plant

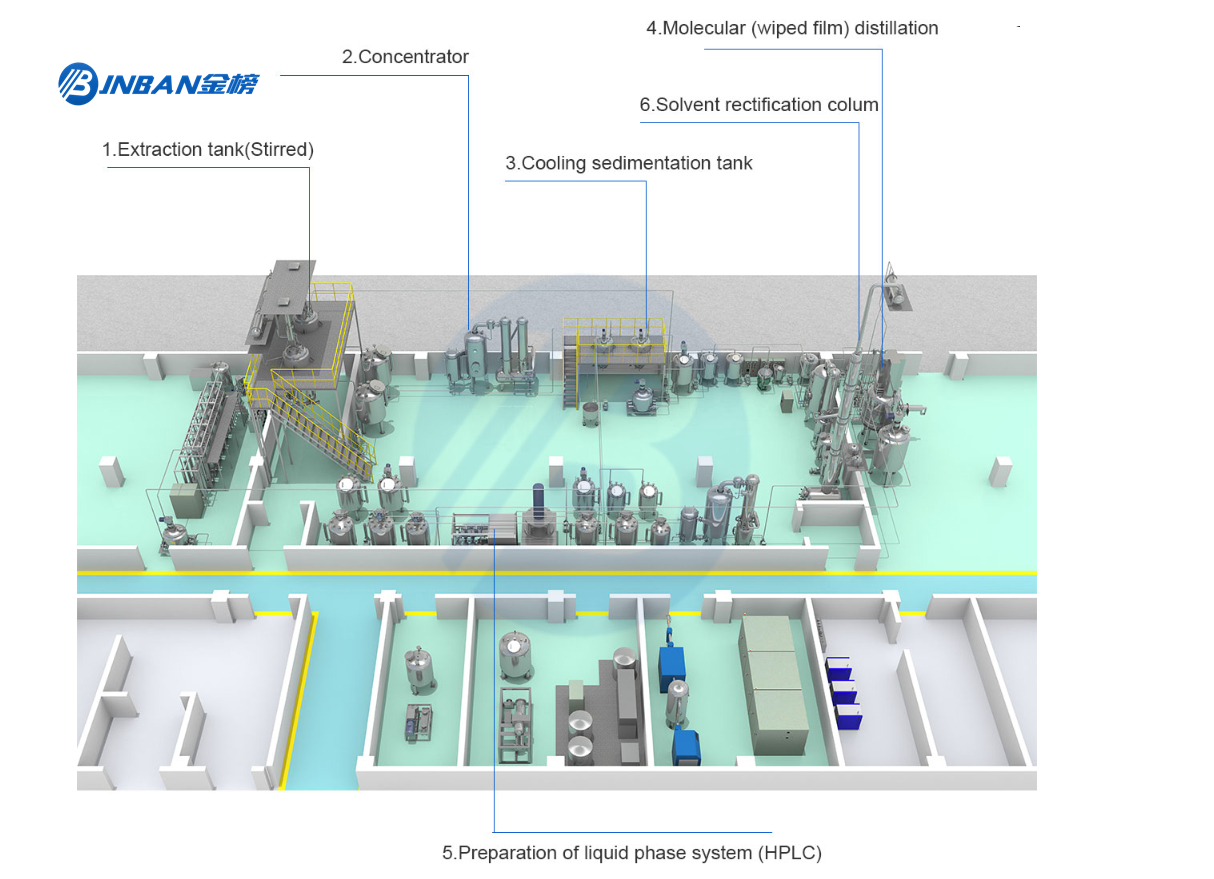

Product Name:Licorice Electric Heating Multifunction Extraction And Concentrator Production Line

Price(USD):65000

Company:Wenzhou JinBang Light Industry Machinery Co., Ltd.

Factory Location: Wenzhou

Main Sales Markets: North America,Western Europe,Eastern Europe,Asia

Monthly Production Capacity: 150 SETS

Contract Manufacturing: CRO,CMO

Packaging Information: Container and Wooden box

Delivery Lead Time: 45 Days

Sample Provided: no

Payment Terms: T/T

The production process of licorice extract typically involves several steps. Here is a general outline of the process:

Raw Material Selection: High-quality licorice roots are selected as the raw material for extraction. Licorice roots contain glycyrrhizin, the main active compound responsible for the sweet flavor and medicinal properties of licorice.

Cleaning and Washing: The licorice roots are thoroughly cleaned and washed to remove any dirt, debris, or impurities.

Cutting and Grinding: The cleaned licorice roots are cut into smaller pieces or ground into a coarse powder. This increases the surface area and facilitates the extraction process.

Extraction: The cut or ground licorice roots are mixed with a suitable solvent, typically water or ethanol. The extraction process can be carried out through various methods, including maceration, percolation, or reflux extraction. The solvent helps to dissolve and extract the active compounds, including glycyrrhizin and other beneficial constituents.

Filtration: After extraction, the mixture is filtered to remove solid particles, plant fibers, or impurities. This step ensures the clarity and purity of the extracted solution.

Concentration: The filtered extract is concentrated to increase the concentration of active compounds. This can be achieved through methods like evaporation or vacuum distillation, which remove the solvent and concentrate the desired constituents.

Purification: Depending on the extraction method and desired purity, further purification steps may be employed. These can include techniques like precipitation, adsorption, or chromatography to isolate and purify specific compounds.

Drying: The concentrated and purified extract is dried to remove any remaining moisture. This can be achieved through methods such as spray drying, freeze-drying, or vacuum drying. Drying helps to stabilize the extract and enhance its shelf life.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

+86 15021993094

Follow Us:

Pharma Sources Insight July 2025

Pharma Sources Insight July 2025