Four years of qualification

Four years of qualification

Audited Supplier

Audited Supplier

In This Store

Category:TCM Machinery > Herbal medicine Drying Equipment

Product Name:industrial lithium fluoride lithium carbonate lithium lithium battery vacuum belt dryer

Price(USD):25000

Company:Wenzhou JinBang Light Industry Machinery Co., Ltd.

Factory Location: wenzhou

Main Sales Markets: North America,Central/South America,Western Europe,Eastern Europe,Australasia,Middle East,Africa

Monthly Production Capacity: 20 sets

Contract Manufacturing: CRO,CMO

Packaging Information: standard export wooden case

Delivery Lead Time: Machine will be finished in about 45 workdays afte

Sample Provided: no

Payment Terms: T/T

industrial lithium fluoride lithium carbonate lithium lithium battery vacuum belt dryer

Product Overview

industrial food fruit vegetable milk salt coffee hemp cocoa beans honey drying machine dryers

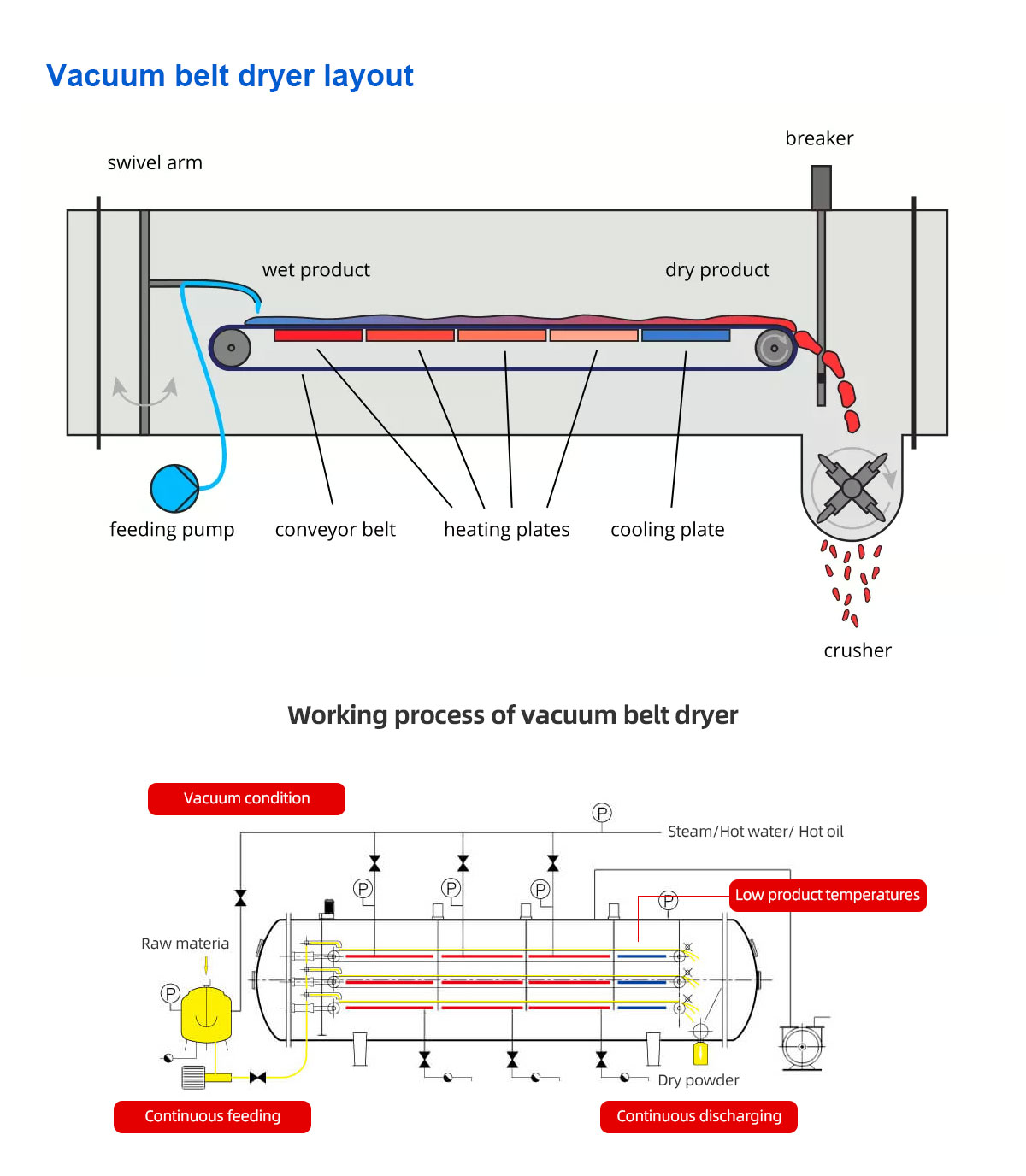

JNBAN Continuous Vacuum Belt Dryer is used for gentle drying of pasty and liquid products like malt mixes, meat extracts,herbal extracts etc. The JNBAN Vacuum Belt Dryer is available from laboratory size to industrial size. Based on precise calculations your JNBAN Vacuum Belt Dryer is customized for your product needs.

JNBAN Belt Vacuum Drying (BVD) is a method of continuously distributing liquid raw materials on a conveyor belt under vacuum conditions.The materials are dried with the conveyor belt on the heating plate, and then cooled, embrittled and pulverized. A low temperature drying method. During the whole drying process, the extract is in a vacuum, closed environment, and the drying process is mild(operating temperature 30-135° C), which can maintain its physical properties to the maximum extent and obtain a high quality final product.Since the material is gradually dried under a vacuum for a period of time, the particles obtained by drying have a certain degree of crystallization effect, and at the same time, there are micropores inside from the microscopic structure. After directly pulverizing to the required particle size, the flowability of the particles is very good, and it can be directly tableted or filled with mash, and the particles have good fast solubility.

FEATURES AT A GLANCE

Advantages for the use of Vacuum Dryers:

● low product temperatures

● minimal loss of flavors

●very small product loss

●no product oxidation

●no mechanical stress to the product

● controllable Maillard reaction

● controllable solubility (instant characteristics) of the dried products

● possibility to recover solvents

● automatic cleaning

Equipment advantages:

● Continuous feeding and continuous discharging under vacuum condition.

● Achieve drying, pulverizing and granulating processes under vacuum.

● Process automation, continuous and pipeline in the drying process.

● Organic solvents can be recycled, no emissions, no pollution.

● System operating costs are 1/3 of vacuum oven and spray drying.

● Shredded mesh 20-120 mesh (adjustable).

● Low temperature and fast drying process will greatly improve product quality.

● According to the characteristics of the material, the corresponding equipment can be carried out online for the drying process parameters.

● Continuous discharge in 30-60 minutes, product recovery rate of more than 99%.

● It can solve the continuous drying of heat sensitive, high sugar and high viscosity materials.

● Complete the granulation process under vacuum to avoid secondary moisture absorption, waste, and pollution.

● The material has excellent instant solubility after drying, which is unmatched by other traditional drying.

● Low labor costs, up to 2 operators.

● It will not pollute the environment due to dust and odor.

● The entire system is automatically controlled by PLC.

● Implement online CIP automatic cleaning.

● The entire system and process meet GMP requirements.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025