Four years of qualification

Four years of qualification

Audited Supplier

Audited Supplier

In This Store

Category:TCM Machinery > Herbal medicine Drying Equipment

Product Name:industrial food fruit vegetable milk salt coffee hemp cocoa beans honey drying machine dryers

Price(USD):25000

Company:Wenzhou JinBang Light Industry Machinery Co., Ltd.

Factory Location: wenzhou

Main Sales Markets: North America,Central/South America,Western Europe,Eastern Europe,Australasia,Middle East,Africa

Monthly Production Capacity: 20 sets

Contract Manufacturing: CRO,CMO

Packaging Information: standard export wooden case

Delivery Lead Time: Machine will be finished in about 45 workdays afte

Sample Provided: no

Payment Terms: T/T

Product Overview

industrial food fruit vegetable milk salt coffee hemp cocoa beans honey drying machine dryers

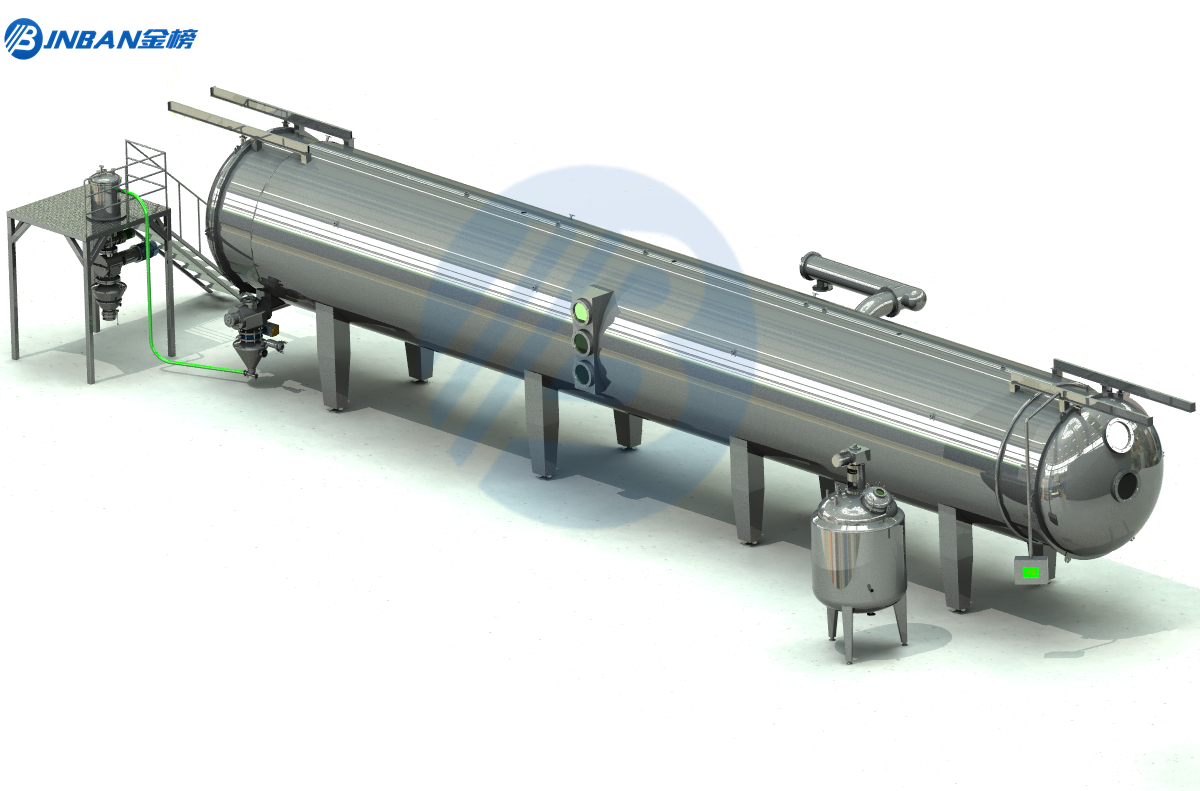

JNBAN Continuous Vacuum Belt Dryer is used for gentle drying of pasty and liquid products like malt mixes, meat extracts,herbal extracts etc. The JNBAN Vacuum Belt Dryer is available from laboratory size to industrial size. Based on precise calculations your JNBAN Vacuum Belt Dryer is customized for your product needs.

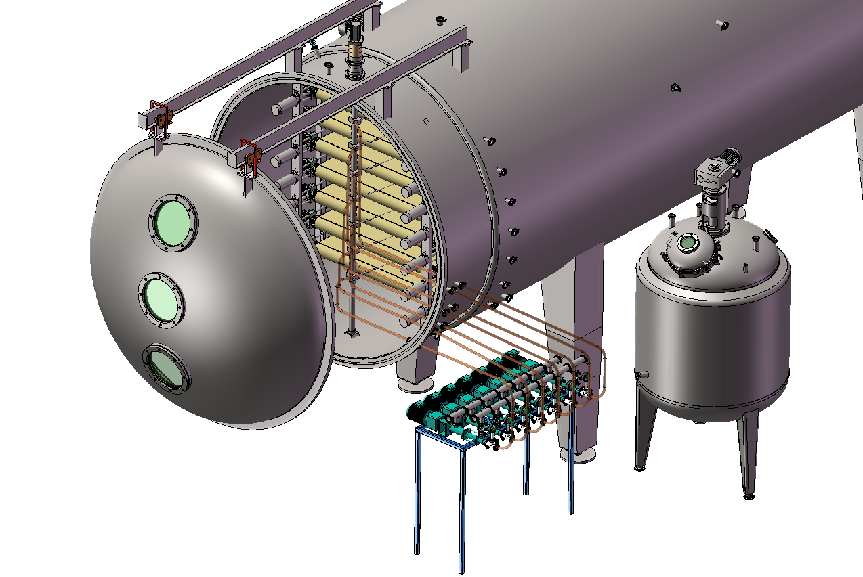

JNBAN Belt Vacuum Drying (BVD) is a method of continuously distributing liquid raw materials on a conveyor belt under vacuum conditions.The materials are dried with the conveyor belt on the heating plate, and then cooled, embrittled and pulverized. A low temperature drying method. During the whole drying process, the extract is in a vacuum, closed environment, and the drying process is mild(operating temperature 30-135° C), which can maintain its physical properties to the maximum extent and obtain a high quality final product.Since the material is gradually dried under a vacuum for a period of time, the particles obtained by drying have a certain degree of crystallization effect, and at the same time, there are micropores inside from the microscopic structure. After directly pulverizing to the required particle size, the flowability of the particles is very good, and it can be directly tableted or filled with mash, and the particles have good fast solubility.

FEATURES AT A GLANCE

Advantages for the use of Vacuum Dryers:

● low product temperatures

● minimal loss of flavors

●very small product loss

●no product oxidation

●no mechanical stress to the product

● controllable Maillard reaction

● controllable solubility (instant characteristics) of the dried products

● possibility to recover solvents

● automatic cleaning

Equipment advantages:

● Continuous feeding and continuous discharging under vacuum condition.

● Achieve drying, pulverizing and granulating processes under vacuum.

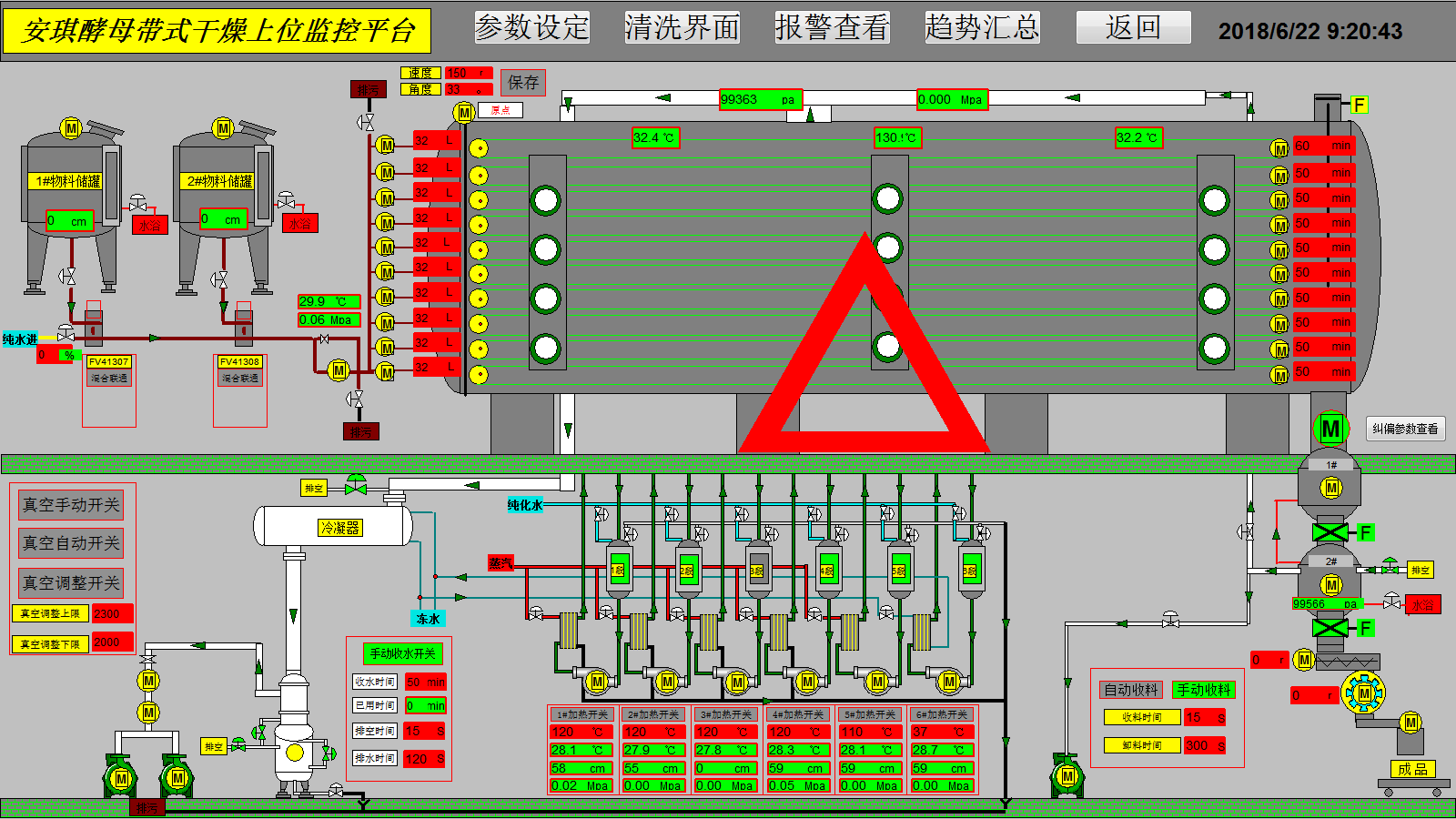

● Process automation, continuous and pipeline in the drying process.

● Organic solvents can be recycled, no emissions, no pollution.

● System operating costs are 1/3 of vacuum oven and spray drying.

● Shredded mesh 20-120 mesh (adjustable).

● Low temperature and fast drying process will greatly improve product quality.

● According to the characteristics of the material, the corresponding equipment can be carried out online for the drying process parameters.

● Continuous discharge in 30-60 minutes, product recovery rate of more than 99%.

● It can solve the continuous drying of heat sensitive, high sugar and high viscosity materials.

● Complete the granulation process under vacuum to avoid secondary moisture absorption, waste, and pollution.

● The material has excellent instant solubility after drying, which is unmatched by other traditional drying.

● Low labor costs, up to 2 operators.

● It will not pollute the environment due to dust and odor.

● The entire system is automatically controlled by PLC.

● Implement online CIP automatic cleaning.

● The entire system and process meet GMP requirements.

VBD Range of Application:

JNBAN Vacuum belt dryer finds its application in a wide range of industries – especially for products that are difficult to dry and process using the traditional dryer techniques. These include, but are not limited to: conventional and western pharmaceutical products, biological products, food, health foods, chemicals, and food additives, etc. We’ve highlighted each of these below.

Food Products

VBDs are used to produce food products such as malt extract, tea powder, corn paste, instant beverage, and cocoa powder. The fineness of the powder and the granules’ size for food products such as coffee can be controlled using specific crusher equipment.

Other food products include: Rice protein powder, hops extract, wheat essence, vegetable juice concentrate, meat extracts,

chocolate products, instant soup, etc.

pharmaceutical products

Pharma products such as Chinese medicine extracts, embryos, plant extracts, and PVPK products are primarily produced using Vacuum Belt Dryers. Other pharma products processed using VBDs are vitamins, fermentation broth, antibiotics, and active medicinal substances, etc.

Chemical Products

VBDs are also used to produce chemical products such as the lithium battery used in a wide range of electric vehicles and emamectin benzoate (an insecticide used in pest control)

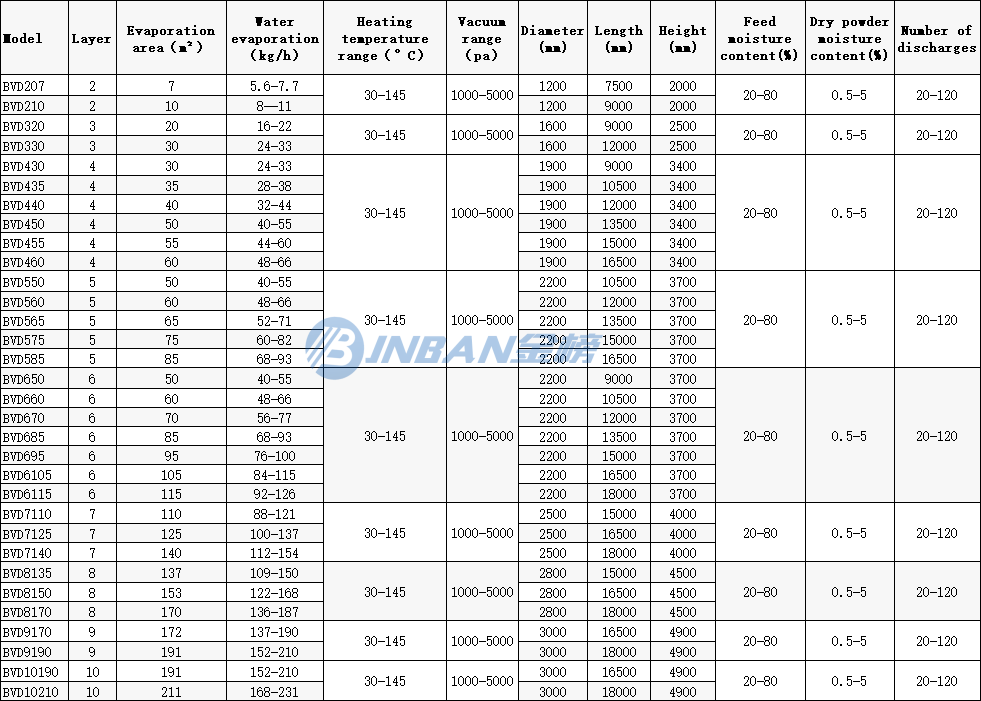

PRODUCT SPECIFICATIONS

PRODUCT CONFIGURATION

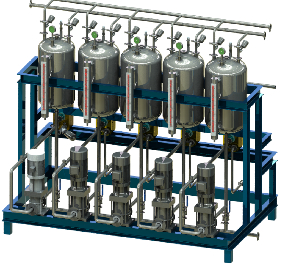

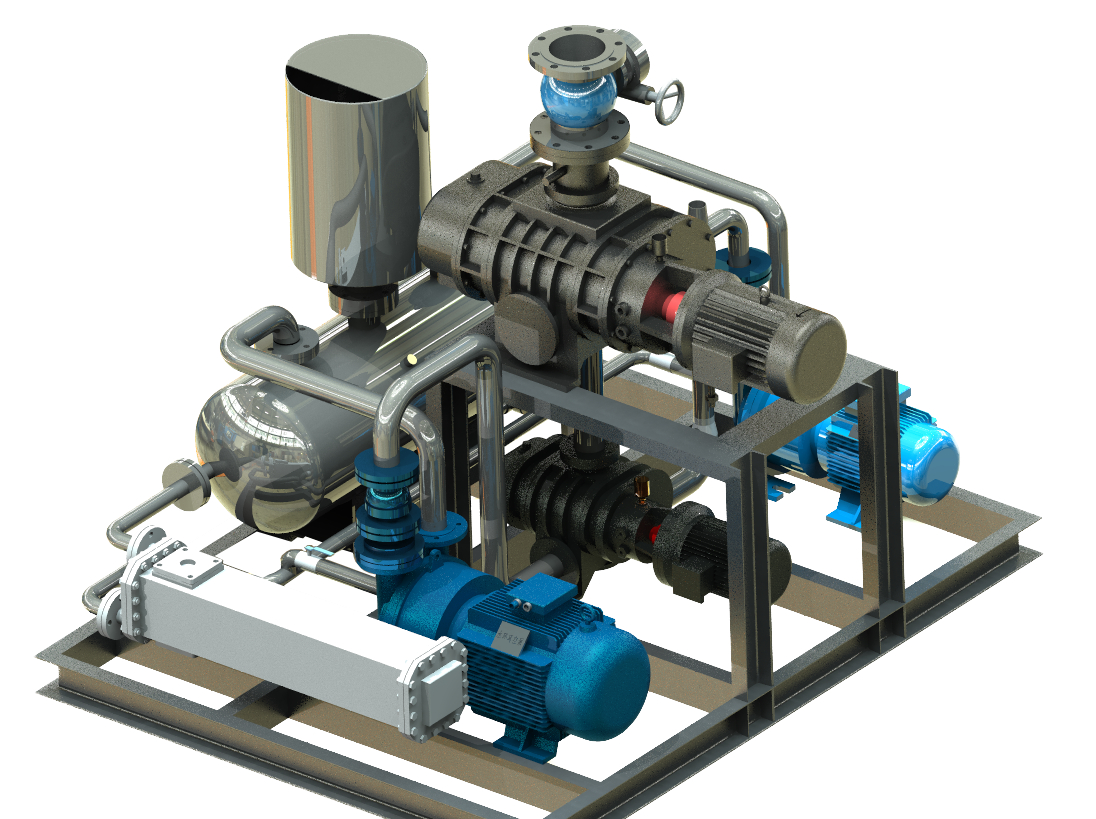

JNBAN Feed System

JNBAN Heating System

JNBAN Vacuuming System

JNBAN Control Cabinet

JNBAN Control System

JNBAN CIP Cleaning System

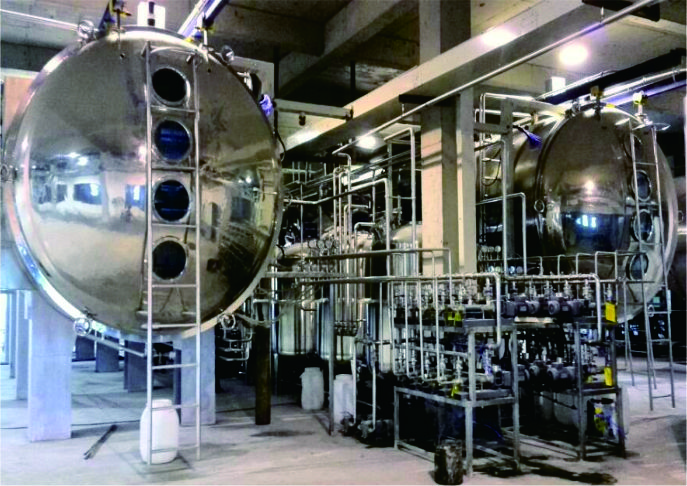

Successful Project

Project in USA

Project in Japan

Project in Netherlands

Project in Turkey

Project in Thailand

Project in Russia

Company Profile

JNBAN vacuum belt dryers have been included in the“ Eleventh Five-Year National Science and Technology Support Program,Zhejiang Science and Technology Department Major Science and Technology Public Relations Project and Zhejiang Province” Major Science and Technology Special (Priority Theme) Social Development Project. There are 4 papers and 6 patent applications accepted, including 4 invention patents, 2 special authorizations, and 10 practical patents. They won the third prize of Zhejiang Science and Technology Progress Award and the first set of products in Zhejiang Province.

Founded in 1997, the company is now located in Wenzhou Binhai Industrial Park, with three production bases, covering an area of 60030 ㎡.

At present, there are 28 senior and medium-level technical personnel, 4 guest professors and more than 300 employees.

JNBAN have class A2 class III pressure vessel design qualification, D1, D2 class I and II pressure vessel manufacturing

qualification, GC2 pressure pipeline installation qualification, and EU CE certification is used for the manufacturing, and the manufacturing meets CMPstandards.

●The only equipment manufacturer in China that has obtained 2 invention patents in the field of vacuum belt dryers.

●China's first manufacturer to independently develop vacuum belt dryer equipment that meets GMP standards.

Certifications

FAQ

Q1:When purchasing a vacuum belt dryer, it is essential to consider the following factors:

●With many VBD types, you need to select one with features that best suit your production needs.

Some of the aspects you consider are the size, the source of heat and achievable temperature range.

● The cost of the vacuum belt dryer is essential to ensure you make a purchase you can pay. Usually, having a budget

guides you on what vacuum bel dryer to buy.

●Your production capacity influences your choice of vacuum belt dryer.

Where you have significant production needs, you need to select a VBD with a large capacity.

● VBDs and other commercial equipment typically have attached warranties that assures you of your product’s quality.

You need to evaluate the warranty option of your VBD with a preference for extended warranties.

● The purchasing process is essential when considering an acquisition of a VBD. Especially when purchasing for

commercial use,you need to ensure you undertake the necessary processes during negotiation.

* Whomever you are purchasing from is another factor of consideration you need to prioritize.

It is prudent to buy from a reputable seller with years of experience and quality.

Q2:What Heat Sources can you Employ for your Vacuum Belt Dryer?

● Steam

● Hot water

● Hot oil

Q3:Purchasing process

●Consultation, test, technical scheme determination, business negotiation, contract.

Q4:How long is the guarantee period

●1 year after finishing installation and commissioning.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025