Eight years of qualification

Eight years of qualification

Audited Supplier

Audited Supplier

In This Store

Category:Preparation Equipment > Preparation Machinery for Solid Medcine > Granulator

Product Name:High Shear Mixing Granulator

Price(USD):Negotiable

Company:Zhejiang Aligned Technology Co., LTD

Factory Location: zhejiang, china

Main Sales Markets: North America,Central/South America,Western Europe,Eastern Europe,Australasia,Asia,Middle East,Africa

Monthly Production Capacity: 1set per month

Packaging Information: stardand wooden case

Delivery Lead Time: 35days

Sample Provided: no

Payment Terms: T/T

Appliation

The machine fully complies with GMP pharmaceutical requirements, featuring low consumption、no pollution, security. It can complete the process of mixing, humidifying, granulating and other at one time,suitable for pharmaceutical、food、chemical and other industries. And it’s 4-5 times higher than the traditional process, which is reflected in about 2 minutes of dry mixing and 1-4 minutes of granulation for each batch. It is mainly composed of conical hopper, impeller, chopper, feeding device, liquid feeding device, discharging and control system, and auxiliary systems such as air sealing, water cleaning, and jacket water cooling. In the container, the material and the binder are fully mixed by the impeller to form a moist soft material, and then cut into uniform wet particles by the high-speed chopper blades.

Working Principle

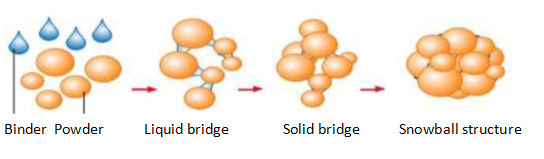

The process consists of two programs including mixing and granulating.

Powder material can be charged into the material pan from the conical hopper and continue to rotate in the container under the action of mixing blade once the hoper is closed. In the meanwhile, all materials grow up the shape of liquid bridge under continuous effects of conical wall. Under the action of extrusion, friction as well as crumb by blade and conical tank wall, all material is gradually turn for loosen. At last while opening the hopper outlet, waterish particles are pushed off under the centrifugal effects blade.

Feature

1. Auto startup of safety pin in fixed position while opening the lid guarantees reliable operation.

2. Belt drive system has advantages of overload protection, simple maintenance, free of oil lubrication and leakage.

3. Oblique designed liner impeller blade applies for the mixture of processed material which drops down at certain height, free of sticking on lid.

4. Container lid is multifunctional design, fitted with observation port, auto/manual dipping port, exhaust port, auto cleaning port, auto spraying port, vacuum loading port.

5. An automatic water circulation system is built under bottom container.

6. Three cycles of seal rings and air seal used for the bearings of impeller and chopper, no dirty or oil backflows to processed container.

7. Air seal system is common for air and water circulation, both for cleaning bearing gaps and pressure setting.

8. Stringent mirror polish technology applied to full container.

9. Outlet Vent filter 0.22 micron allowing evacuation of compressed air used in air purged impeller and chopper seals.

10. Conical sieve mill (Wet Mill) is mounted on discharge port, equipped with milling screen and two rotor arms (square or round) or triangular blades that rotates at a speed up to 3000 RPM (Option).

Technical Parameters

|

型号 model |

HLSG-10 |

HLSG-30 |

HLSG-50 |

HLSG-100 |

HLSG-200 |

HLSG-300 |

HLSG-400 |

HLSG-600 |

HLSG-800 |

|

|

料斗容积Hopper capacity |

10L |

30 |

50L |

100L |

200L |

300L |

400L |

600L |

800L |

|

|

工作容量Working capacity |

2-8L |

6-24 |

10-40 |

20-80 |

40-160 |

60-240 |

100L-300L |

150L-440L |

200L-600L |

|

|

投料量(设比重0.5克/立方厘米)Feed qty (set specific gravity 0.5 g/cm3) |

1-4公斤/批次 1-4 Kg/batch |

3-12公斤/批次 3-12 Kg/batch |

8--20公斤/批次 8--20Kg/batch |

15--40公斤/批次 15--40 Kg/batch |

30--80公斤/批次30--80Kg/batch |

30---120公斤/批次 30--120Kg/batch |

50—150公斤/批次50-150Kg/batch |

75—220公斤/批次75-220Kg/batch |

100—300公斤/批次100-300Kg/batch |

|

|

操作时间 operation time |

混合约2分钟 制粒约7-14分钟/批 Mixing about 2 minutes granulating about 7-14 minutes each batch |

混合约2分钟 制粒约7-14分钟/批 Mixing about 2 minutes granulating about 7-14 minutes each batch |

混合约2分钟 制粒约7-14分钟/批 Mixing about 2 minutes granulating about 7-14 minutes each batch |

混合约2分钟 制粒约7-14分钟/批 Mixing about 2 minutes granulating about 7-14 minutes each batch |

混合约2分钟 制粒约7-14分钟/批 Mixing about 2 minutes granulating about 7-14 minutes each batch |

混合约2分钟 制粒约7-14分钟/批 Mixing about 2 minutes granulating about 7-14 minutes each batch |

混合约4分钟 制粒约10-15分钟/批 Mixing about 4 minutes granulating about 10-15 minutes each batch |

混合约8分钟 制粒约15-20分钟/批 Mixing about 8 minutes granulating about 15-20 minutes each batch |

混合约8分钟 制粒约5-15分钟/批 Mixing about 8 minutes granulating about 15-20 minutes each batch |

|

|

成品粒度 Finished product granularity |

约Φ0.14-Φ1.5mm(12目-100目) About Φ0.14-Φ1.5mm (12 mesh-100 mesh) |

约Φ0.14-Φ1.5mm(12目-100目) About Φ0.14-Φ1.5mm (12 mesh-100 mesh) |

约Φ0.14-Φ1.5mm(12目-100目) About Φ0.14-Φ1.5mm (12 mesh-100 mesh) |

约Φ0.14-Φ1.5mm(12目-100目) About Φ0.14-Φ1.5mm (12 mesh-100 mesh) |

约Φ0.14-Φ1.5mm(12目-100目) About Φ0.14-Φ1.5mm (12 mesh-100 mesh) |

约Φ0.14-Φ1.5mm(12目-100目) About Φ0.14-Φ1.5mm (12 mesh-100 mesh) |

约Φ0.14-Φ1.5mm(12目-100目) About Φ0.14-Φ1.5mm (12 mesh-100 mesh) |

约Φ0.14-Φ1.5mm(12目-100目) About Φ0.14-Φ1.5mm (12 mesh-100 mesh) |

约0.10-Φ2.5mm About Φ0.10-Φ2.5mm |

|

|

混合电机 Mixing motor |

2.2KW |

3KW |

5.5KW |

7.5KW |

15KW |

18.5KW |

22KW |

30KW |

37KW |

|

|

混合浆转速(变频调速)Mixing blade rotating speed (Frequency conversion speed-adjusting) |

50-500转/分 rpm

|

25-500转/分rpm

|

25-500转/分rpm

|

30-250转/分rpm

|

30-260转/分rpm

|

30-220转/分rpm

|

20-200转/分rpm

|

20-200转/分rpm |

20-200转/分rpm

|

|

|

制粒电机 Granulating motor |

0.75KW |

1.1KW |

1.5KW |

3KW |

4KW |

5.5KW |

7.5KW |

11KW |

11KW |

|

|

制粒浆转速(变频调速)Granulating blade rotating speed (Frequency conversion speed-adjusting) |

50-3000转/分rpm |

50-3000转/分rpm |

50-3000转/分rpm |

50-3000转/分rpm |

50-3000转/分rpm |

50-3000转/分rpm |

50-3000转/分rpm |

50-3000转/分rpm |

50-3000转/分rpm |

|

|

压缩空气 compressed air |

0.15立方米 0.7Mpa 0.15m3 0.7mpa |

0.15立方米 0.7Mpa 0.15m3 0.7mpa |

0.3立方米 0.7Mpa 0.3m3 0.7mpa |

0.3立方米 0.7Mpa 0.3m3 0.7mpa |

0.3立方米 0.7Mpa 0.3m3 0.7mpa |

0.5立方米 0.7Mpa 0.5m3 0.7mpa |

0.5立方米 0.7Mpa 0.5m3 0.7mpa |

0.5立方米 0.7Mpa 0.5m3 0.7mpa |

0.6立方米 0.7Mpa 0.6m3 0.7mpa |

|

|

冷却水接口cooling water connector

|

Φ8mm |

Φ8mm |

Φ8mm |

Φ8mm |

Φ10mm |

Φ10mm |

Φ10mm |

Φ10mm |

Φ12mm |

|

|

压缩空气口 Compressed air port |

Φ8mm |

Φ8mm |

Φ8mm |

Φ8mm |

Φ10mm |

Φ10mm |

Φ10mm |

Φ10mm |

Φ12mm |

|

|

主机尺寸(L×w×H) Mahcine size(L×B×H) |

1280×530×1320 mm |

1500×550×1350 mm |

1750×600×1620 mm |

1760×600×1660 mm |

2180×810×1950mm |

2420×1060×2150mm |

2420×1060×2150mm |

2980×1200×2500mm |

3180×1500×2800mm |

|

|

重量weight |

350kg |

450kg |

600kg |

800kg |

1300kg |

1500Kg |

1800kg |

2200kg |

2700kg |

|

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025