Eleven years of qualification

Eleven years of qualification

Audited Supplier

Audited Supplier

In This Store

Category:Preparation Equipment > Preparation Machinery for Solid Medcine > Granulator

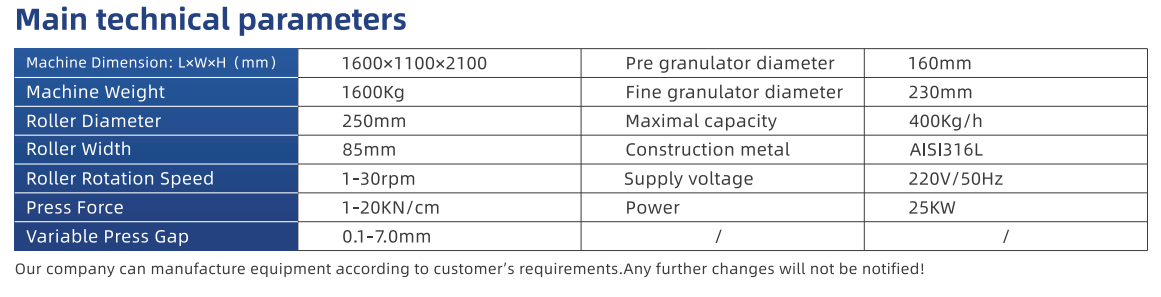

Product Name:HERCULES-85 ROLLER COMPACTOR

Price(USD):Negotiable

Company:Canaan

Factory Location: Nanjing, China

Main Sales Markets: North America,Central/South America,Western Europe,Eastern Europe,Australasia,Asia,Middle East,Africa

Sample Provided: yes

Payment Terms: L/L

ROLLER COMPACTOR SERIES

In order to obtain high quality particles, two-stage granulation mode is adopted, the first stage is prefabricated granulation and the second stage is final granulation. The specially designed rotors can granulate different kinds of materials. The speed and direction of the first and second granulation rotors can be adjusted separately.

Efficient Two-stage Granulation

The Hercules-85 roller compactor provides a two-stage granulation system for high quality granulates. With this soft mode granulation we can guarantee a minimal amount of undersized particles.

Automatic HMI Control

The Hercules-85 roller compactor uses IPC(lndustrial Personal Computer)which is easy to operate and has a friendlier HMI.

Unique Feeding System

With the synchronous operation mode of horizontal and vertical feeding, the unique operation control can ensure that the material will not be blocked during the process of conveying from horizontal metering screw to vertical metering screw.

Isolated Granulation Area

The equipment separates the granulation area from the driving device area through the equipment box, and isolates the granulation area from the external environment through the equipment door and the sealing strip, thereby reducing dust pollution during the production and avoiding material spillage or contamination.

Especial Unit for Test

The two vertical metering screws are operated in two chambers of the feed bucket, and the two chambers each occupy half of the width of the press roller, so that equipment can choose to continuously transport a small amount of material for test. In order to meet the test run, the Hercules-85 dry granulator also provides a small volume of manual feed hopper. Once the material is added, it can be delivered directly to the inside of the equipment through the vertical metering screw. Small batch tests can be carried out without changing the structure of the machine. The experimental data and operating parameters obtained can be applied to mass production.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025