Twelve years of qualification

Twelve years of qualification

Audited Supplier

Audited Supplier

In This Store

Category:API Equipment > Drying Equipment

Product Name:GLP-300 HIGH SPEED CENTRIFUGAL SPRAYING DRYER

Company:Jiangyin Snynxn Granulating Drying Equipment Co.,Ltd

Factory Location: Jiangyin City,Jiangsu,China

Main Sales Markets: North America,Central/South America,Western Europe,Eastern Europe,Asia,Middle East,Africa

Monthly Production Capacity: 10

Contract Manufacturing: CMO

Packaging Information: Export wooden box

Delivery Lead Time: 2-4months

Sample Provided: no

Payment Terms: T/T

Descriptions

The centrifugal spray dryer is the widely used technology in the liquid shaping technology and drying industry.Lt is most suitable for producing powder, particle solid products from materials of solution, emulsion, solidus and culpable paste states, Therefore, when the particle size of the distribution final products, the residual water contents, the stocking density and the particle shape meet the precision standards, the centrifugal spray dryer is one of the most desired technologies.

_副本.png)

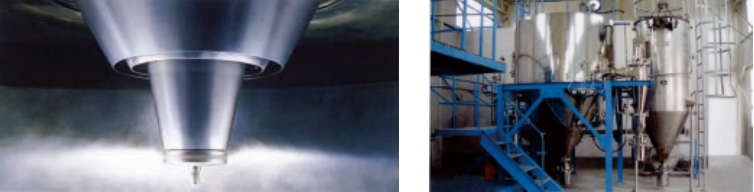

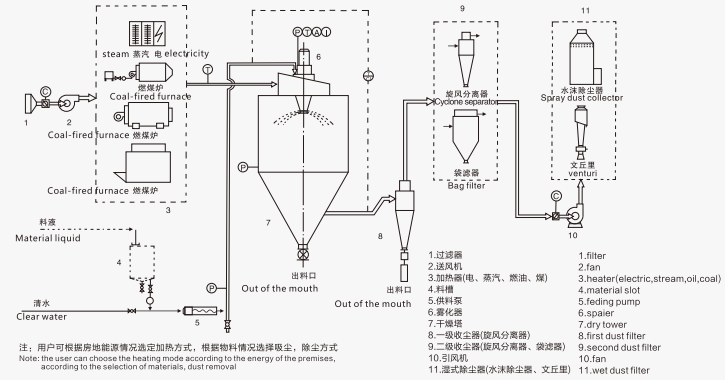

Principle of work

After filtering and heating, the air enters air distributor at the top of the dryer. The hot air enters the e drying chamber in the spiral form uniformly. By passing through the high-speed centrifugal atomizer at the top of the tower, the material liquid will be rotated and sprayed into extremely fine mist liquid beads, Through the very short time of contacting with hot air, the materials can be dried into the finished products. The finished products will be discharged continuously from the bottom of the drying tower and from the cyclone separator.The waste gas will be discharged by blower.

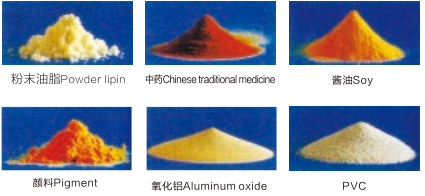

Dried samples

Foodstuff: Amino acid、Vitamin、flavoring、protein、dried milk、pig blood powder、soy powder、coffee、tea powder、Glucose、potassium、sorbe、pectin、 essence、vegetable juice、yeast、starch etc.

Ceramics: Alumina、Marconi、magnesium oxide、titanium oxide、magnesium titanate、pottery clay、china clay、all kinds of magnetic porcelain and metal-oxides etc.

Chemical products: Dispersed dyestuff、active dyestuff、organic catalyst white carbon black、detergent powder、zinc sulfate、sodium metasilicat、potassium fluoride、calcium carbonate、tribasic potassium phosphate、inorganic catalyst and all kinds of waste liquid etc.

Description: Powder Spraying Dryer Machine

Spray dryer is suitable for solution, suspension, slurry, paste material, etc. Liquid material is atomized to small fog drops. And fog drops contact with hot air directly in the drying tower. Moisture content is evaporated instantly. So spray dryer features high efficiency, high mass transfer area, and short drying time, in general it is 5~30 seconds. Operating temperature can be adjusted according to actual situation, in general inlet air temperature is 150~500°C. And its automation control degree is control, environment solution environment can be solved.

Application of GLP Spray Dryer:

Foodstuff industry: Amino acid and similar substance, flavoring, protein, starch, dairy products, instant coffee, fish powder, meat powder, tomato paste and so on.

Pharmaceutical Industry: Chinese patent medicine, agrochemical, antibiotics, medical drinking agent and so on.

Chemical industry: Organic catalyst, resin, synthetic washing powder, thiamin, dyestuff, intermediate of dyestuff, intermediate of dyestuff, white carbon black, graphite, ammonium phosphate and so on.

Ceramic industry: Magnesium oxide, kaolin, metallic oxide, dolomite and so on.

Flow diagram

Features and Outlines

Features

1 .High speed of drying. After the spraying of the material liquid, the surface area of the material will be increased greatly. In the hot-air flow,95%-98% of water can be evaporated at the moment.The time of completing the drying needs only several seconds.lt is especially suitable for drying the heat sensitive materials.

2. Ats final products own the good uniformity, mobility, and dissolving capacity. And the final products are high in purity and good in quality,

3. The production procedure is simple and the operational control easy. The liquid with the moisture contents 40-60% (for special materials, The contents may reach 90%.)can be dried into powder or particle products at a time. After the drying, there is no need tor smashing and sorting, so as to reduce the operation procedures in the production and Chance the product purity .The product particle diam enters, looseness and water contents can be adjusted through changing the operation condition in a certain scope, It is very convenient to carry out the control and management.

Outlines

1. Atomization: Atomizing system must ensure a uniform distribution of the fog drops, which is crucial to ensure a good qualified rate of products.

2. Contact of hot airflow and fog drops: When enough hot air enters into drying tower, the direction and angle of hot air flaw have to be considered, no matter co-current flow, adverse current or mixed flow, must ensure the sufficient heat exchange, it is crucial.

3. The angle design of pipelines and cone: Lt is very important to select the suitable angle, here we would like to share our experience and data from production of thousands of this equipment.

Technical parameters

| 型号 Model | 5 | 25 | 50 | 100 | 150 | 200-10000 |

| 入口温度℃ Inlet temperature | 140-350 自控 140-350 automatic control | |||||

| 出口温度℃ outlet temperature | ~80-90 | |||||

| 水份最大蒸发量kg/h Maximum moisture evaporation | 5 | 25 | 50 | 100 | 150 | 200-10000 |

| 离心喷雾头传动形式 Centrifugal spray head drive | 压缩空气传动 Compressed air drive | 机械传动 mechanical drive | ||||

| 转速(r.p.m) speed | 25000 | 18000 | 18000 | 18000 | 15000 | 8000-15000 |

| 喷雾盘直径(mm) Spray disc diameter | 50 | 100 | 120 | 140 | 150 | 180-340 |

| 热源 heat source | 电 electric | 电+蒸汽 Electricity + steam | 电+蒸汽、燃油煤气 Electricity + steam, fuel, gas | 由用户自行解决 Resolved by the user | ||

| 电加热最大功率kW Maximum power of electric heating | 9 | 36 | 63 | 81 | 99 | |

| 外形尺寸L×W×H(m) Outline dimension | 1.8×0.93×2.2 | 3×2.7×4.26 | 3.7×3.2×5.1 | 4.6×4.2×6 | 5.5×4.5×7 | 根据具体情况确定 Determined according to specific circumstances |

| 干粉回收率% Dry powder recovery | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 |

Note: evaporation of water is related to the characteristics of the material and the temperature of the inlet and outlet

Our Factory

SNYNXN is specialized in design, development, manufacture and sale of pharmaceutical, food, chemical extracting and drying equipments for more than 20 years. Our products include Dryer, Granulator, Mixer, Crusher, Evaporator and distiller etc.

Looking to the future with a commitment to design innovation and quality products, supported by an outstanding level of customer service. The unexcelled quality medical machinery can be easily obtained from us because we maintain the quality and standard of our products from incoming raw materials to the finished products.

Our company follows strict quality controls and various systematic procedures. We take utmost care of quality at every stage of the manufacturing process. Our research and development wing is our asset that develops and incorporates innovative ideas and products.

Our Team is full of experienced and qualified professionals, who have sound knowledge about the quality of our medical machinery. Our products are far sold to Europe, U.S.A., and the southeast Asia. They are well received by customers both at home and abroad.

Pre-sales Service:

1. Inquiry and consulting support

2.Sending machine video for reference

3.Testing machine before delivery according to requirements.

4.View our Factory

After-sales Service

Help training customer operation machine

Solve the customer's problem when machines in use through online video

The large equipment or complex machine, appointed engineer overseas service.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025