Twelve years of qualification

Twelve years of qualification

Audited Supplier

Audited Supplier

In This Store

Category:Preparation Equipment > Preparation Machinery for Solid Medcine > Mixing Equipment

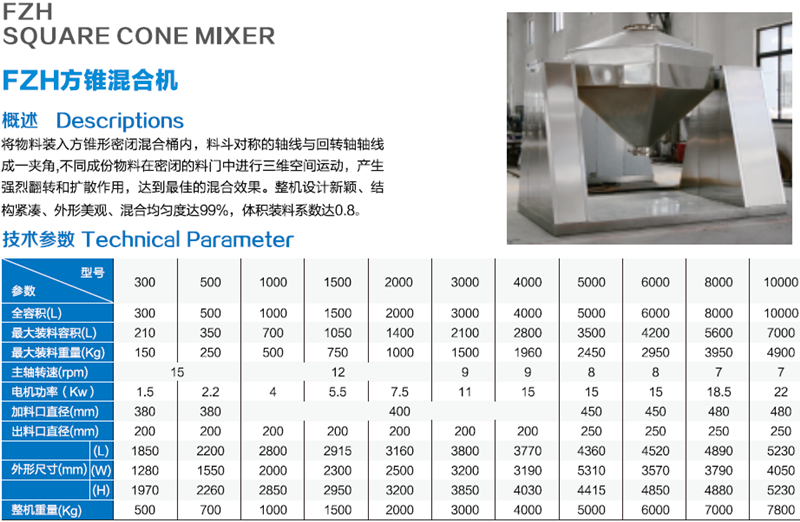

Product Name:FZH SQUARE CONE MIXER

Price(USD):5000US$-30000US$

Company:Jiangyin Snynxn Granulating Drying Equipment Co.,Ltd

Factory Location: Jiangyin City,Jiangsu,China

Main Sales Markets: North America,Central/South America,Western Europe,Eastern Europe,Australasia,Asia,Middle East,Africa

Monthly Production Capacity: 10

Contract Manufacturing: CMO

Packaging Information: Export wooden box

Delivery Lead Time: 2 months

Sample Provided: no

Payment Terms: T/T

I. purpose:

This machine is mainly used for the mixing of granule and granule, granule and powder, powder and powder and other materials in the production of solid pharmaceutical industry. At the same time in the pharmaceutical, chemical, food and other industries widely used.

II. Principle

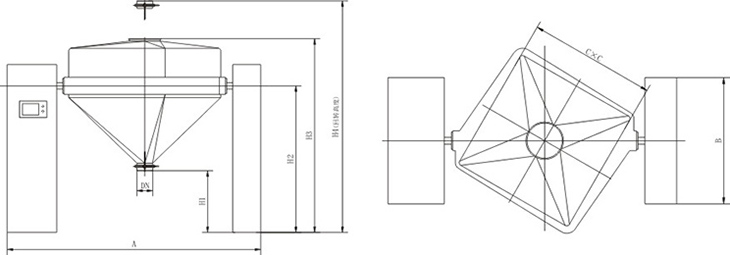

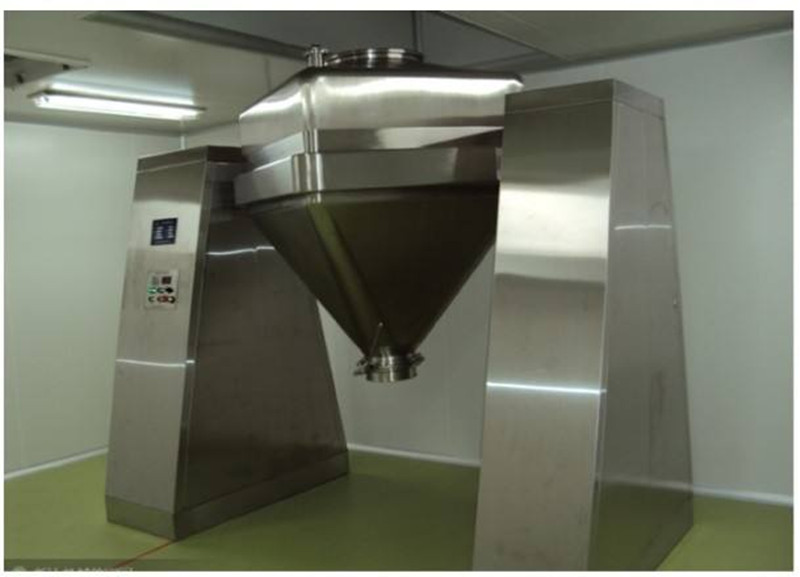

The machine consists of base, drive system, control system, mixed hopper, etc. When working, after adding the material into the hopper, lock the cover, set the mixing time and mixing speed according to the process requirements, and start the control system to start the mixing operation. After the set time, the whole machine will stop vertically automatically, and the sorting work will start after the end of mixing. FZH series structure features are: fixed the hopper mixing machine mixing hopper into 30 ℃ and rotation axis Angle. In the mixing operation, the materials in the mixing hopper not only flip with the hopper, but also make tangential movement along the inner wall of the hopper, so that the materials will have a strong turnover and a high tangential movement to achieve the best mixing effect.

III(3) features:

3.1 reasonable structure, stable and reliable performance, convenient operation.

3.2 the whole machine has no dead Angle, no concave and convex surface and no exposed screws.

3.3 all turning angles of the inner and outer surfaces of the mixing hopper are over arc, without dead Angle or residue.

3.4 both internal and external surfaces of the hopper are highly polished. The inner surface roughness reaches Ra 0.6um and the outer roughness reaches Ra 1. 2 um.

3.5 the cover is provided with silicone rubber seal to ensure the tightness during mixing.

3.6 specially designed butterfly valve is easy to clean, with anti-misoperation device, reliable seal, flexible operation.

3.7 mixing uniformity reaches over 99%.

3.8 fully comply with GMP requirements for drug production

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025