Twelve years of qualification

Twelve years of qualification

Audited Supplier

Audited Supplier

In This Store

Category:Preparation Equipment > Preparation Machinery for Solid Medcine > Granulator

Product Name:FL FLUID-BED GRANULATOR(ONE-STEP GRANULATOR)

Price(USD):15000-95000$

Company:Jiangyin Snynxn Granulating Drying Equipment Co.,Ltd

Factory Location: Jiangyin city,Jiangsu,China

Main Sales Markets: North America,Central/South America,Western Europe,Eastern Europe,Australasia,Asia,Middle East,Africa

Monthly Production Capacity: 30

Contract Manufacturing: CMO

Packaging Information: EXPORT WOODEN BOX

Delivery Lead Time: 2-3 months

Sample Provided: no

Payment Terms: T/T

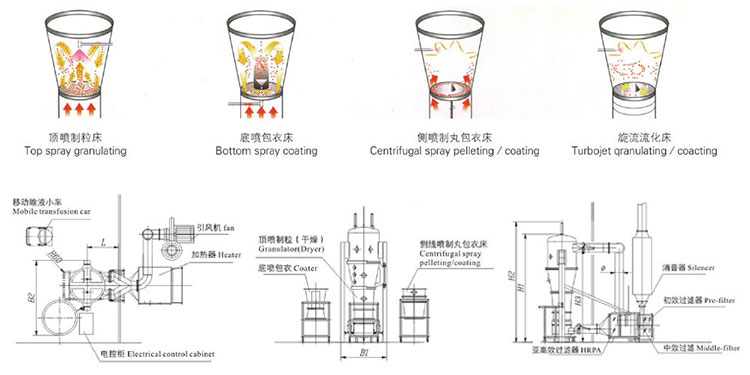

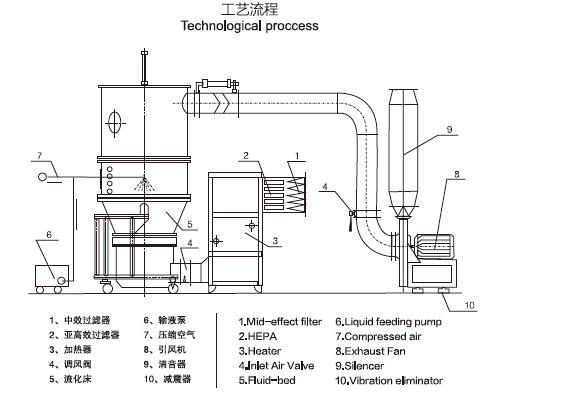

Principles

The powder granule in the container (fluidization)appear in the state of fluidization. It is preheated and mixed with clean and heated air. At the same time the solution of adhesive solvent is fogged and sprayed into the container. It makes the some particles become granulating that contains adhesive. Being of unceasing dry through hot air, the moisture in the granulation is evaporated and the adhesive is solidification. The process is carried out continuously. Finally it forms ideal, uniform and Porous granules.

Features

●Because of powder granulation, the fluidity is improved and the dust is reduced;

●Because of powder granulation, its solving property is improved;

●The mixing, granulation and drying can be completed in one step inside the machine;

●The operation of equipment is safe because the anti static filtering cloth is adapted;

●The operating personnel can not be damaged if explosion take place because there is releasing hole;

●The equipment has no dead corner. Therefore the loading and unloading are quick and light and clean. It can meet the requirements of GMP.

Applications

●Pharmaceutical industry: tablet, capsule, low sugar or no sugar granule of Chinese medicine.

●Foodstuff: cocoa, coffee, milkpowder, juice of granulate, flavoring and so on.

●Other industries: pesticide, feed chemical fertilizer, pigment, dyestuff and so on.

●The drying of wet powder and granule.

●Coating: protective layer,coloration,control releasing,film and enteric-releasing slow of granule and pellet.

Coating: protective layer,coloration,control releasing,film and enteric-releasing slow of granule and pellet.

Technical parameters

| Item | 单Unit | 机型type | |||||||||||||||||

| 3 | 5 | 15 | 30 | 60 | 120 | 200 | 300 | 500 | |||||||||||

| 原料容器 Container | 容量Volume | L | 12 | 22 | 45 | 100 | 220 | 420 | 670 | 1000 | 1500 | ||||||||

| 直径 Diameter | mm | 300 | 400 | 550 | 700 | 1000 | 1200 | 1400 | 1600 | 1800 | |||||||||

| 生产能力 Capability | 最小Min | Kg | 1.5 | 4 | 10 | 15 | 30 | 80 | 100 | 150 | 250 | ||||||||

| 最大Max | Kg | 4.5 | 6 | 20 | 45 | 90 | 160 | 300 | 450 | 750 | |||||||||

| 风机Fan | 风量Capacity | m3/h | 1000 | 1200 | 1400 | 1800 | 3000 | 4500 | 6000 | 7000 | 8000 | ||||||||

| 风压Pressure | mmH2O | 375 | 375 | 480 | 480 | 950 | 950 | 950 | 950 | 950 | |||||||||

| 功率Power | kw | 3 | 4 | 5.5 | 7.5 | 11 | 18.5 | 22 | 30 | 45 | |||||||||

| 蒸汽消耗量Steam consumption | Kg/h | 9 | 12 | 42 | 70 | 141 | 180 | 282 | 366 | 451 | |||||||||

| 压缩空气耗量 Compressed air consumption |

m3/min | 0.3 | 0.35 | 0.6 | 0.6 | 0.9 | 0.9 | 1.1 | 2.0 | 2.4 | |||||||||

| 主机重量Weight of the main body | Kg | 500 | 700 | 900 | 1000 | 1100 | 1300 | 1500 | 1800 | 2000 | |||||||||

| 蒸汽压力Steam pressure | Mpa | 0.3-0.6 | |||||||||||||||||

| 温度 Temperature | ℃ | 室温-120℃范围内可调节(adjustable at the range from room temperature to 120℃) | |||||||||||||||||

| 作业时间Working time | min | 随物料特性而定45~90 ( decided in accordance with the proplerties of raw materials } | |||||||||||||||||

| 物料收得率Yield | % | ≥99 | |||||||||||||||||

| 噪声Noise | dB(A) | 风机与主机隔离安装,噪声≤75dB{A)(When installation,main machine is separated from fan) | |||||||||||||||||

| 主机外型尺寸 Size{L×W×H) |

m | 1.0× 0.6×2.1 | 1.2×0.7×2.1 | 1.25×0.9×2.5 | 1.6×1.1×2.5 | 1.85×1.4×3 | 2.2×1.65×3.3 | 2.34×1.7×3.8 | 2.8×2.0×4.0 |

3×2.25 |

|||||||||

OUR FACTORY:

Packing: The product will be packed in wooden case, and also can be packed in other ways as your request. Both neutral and customized packing is available.

Shipping: We can ship the goods to you by international express, such as DHL, UPS, TNT and so on. And you can choose the appropriate way based on your timeline and budget. Besides, you can choose to use your own shipping agent.

Express: Door to door, very convenient, don't need clearance or pick-up.

By air: Form Airport to the airport, you need to do the customs clearance and pick up the goods at your local airport, which you can have a local shipping agent do for you.

By sea: Port to port and you need to do the customs clearance and pick up the goods at your local port, which you can have a local shipping agent do for you.

Company Information:

SNYNXN is a comprehensive company integrating R&D, production and sales. We carefully design and manufacture food and pharmaceutical processing equipment for customers around the world. Based on product quality, we constantly pursue technological innovation, expand and improve our product line. We have first-class scientific research talents, a professional sales team, and perfect after-sales service to ensure that you can use our products without worry in the whole process.

Since its establishment, our company has developed various products, including drying ovens, spray dryers, freeze dryers, granulators, industrial dryers, mixing machines, etc. Our products are best-selling all over the world and have gained wide praise, which are applied in food, pharmacy, chemical industry, schools, scientific research institutions and other fields. In production, we have established a complete quality management system to ensure product quality, realize safe production, and strive to produce attractive appearance, practical, stable, and cost-effective products. We will always serve you sincerely and believe that SNYNXN will become your preferred supplier.

Our Services

Pre-sale service:

--24 Hours online service.

--Help choose the right model with a series of services and advice.

--Provide you with the best quote offer.

--Provide discount for bulk orders.

--Meet your customized requirement.

--Choose a payment term convenient for you.

--Promptly production and delivery of information.

--Provide invoice.

After-sale service:

--Product installation support.

--Technical Engineers are available.

--Remote control technical consultation.

--1 year warranty service and lifelong maintenance.

FAQ

Q: How does the machine fit our voltage?

A: For each piece of equipment, our salesman will confirm the voltage with the customer.

Q: How can I buy the machine?

A: Firstly, our salesman will discuss with you all the details of the machine, the lead time and the payment condition.

Secondly, after receiving the 30% down payment, the production will begin.

Finally, we’ll show you the photos and the test video of the finished machine. You pay the balance and the equipment will be shipped as scheduled, by our forwarder or by your familiar forwarder.

Q: How long is your machine’s warranty?

A:1 year after the delivery. During the one year, we can offer the broken parts free of charge, if the problem isn’t caused by wrong operation.

Q. What can you provide for after-sale service?

A: We can send the engineer to the customer’s factory for the installation and operation training if the customer requires it. We can also supply the installation and operation instructions by video.

Q: If we have a very special request on the production line, could you help me to do the design?

A: Customized design is provided.

Q: How to contact you?

A: Please leave messages and click "send" to send us inquiries.

Need more machines details and videos? Please contact us directly!

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025