Eight years of qualification

Eight years of qualification

Audited Supplier

Audited Supplier

In This Store

Category:Preparation Equipment > Preparation Machinery for Solid Medcine > Granulator

Product Name:DPL-II Multi-functional fluid bed processor

Price(USD):Negotiable

Company:Zhejiang Aligned Technology Co., LTD

Factory Location: zhejiang, CHINA

Main Sales Markets: North America,Central/South America,Western Europe,Eastern Europe,Australasia,Asia,Middle East,Africa

Monthly Production Capacity: 1set per month

Packaging Information: standard export wooden case

Delivery Lead Time: 40 days

Sample Provided: no

Payment Terms: T/T

Application

The machine is equipped with a top, bottom, and side spray systems, which can realize functions such as drying, granulating, coating, and granulation. This machine is one of the main process equipment in the production process of solid preparations in the pharmaceutical industry. It is mainly equipped with scientific research institutes and laboratories of major pharmaceutical companies and medical colleges and is used for product formulation and prescription processes in the pharmaceutical, chemical, and food industries. Research and development trial production experiments.

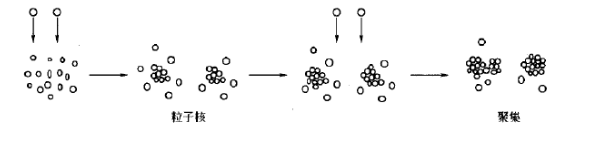

Working Principle of Granulating

The formation of particles is that when the binder is sprayed on the suspended and loose materials, the binder droplets wet the powder in contact and coalesce around themselves to form particle nuclei, and at the same time, the droplets that continue to spray fall on the particles. Bonding and bridging are generated on the surface of the particle core, so that the particle core and the particle core are cross-linked and bonded to each other, and gradually agglomerate and grow into larger particles.

Working Principle of Drying

In the fluidized bed drying process, the temperature usually changes in three stages: in the first stage of drying, the material temperature is gradually heated from room temperature to the wet bulb temperature of hot air;in the second stage, the material keeps the wet bulb temperature of the hot air unchanged until the moisture content of the material drops to the critical humidity, at which time the material no longer contains free moisture; then, in the third stage of temperature rise, the material loses bound water.When drying, the inlet air temperature should not be too high, the solvent on the surface of the particles evaporates too quickly, and the inner layer of the solvent is blocked from diffusing outward, resulting in a large number of particles with dry outer temperature and inner temperature. If the temperature is too low and the drying time is too long, a lot of fine powder will be produced.

Feature

● Modular design, the machine is equipped with a top, bottom, and side spray systems, which can realize functions such as drying, granulating, coating, and granulation.

● The machine has a compact design, its easy to disassemble and clean, has no sanitary corners, and meets the requirements of cGMP production specifications.

● The temperature control is accurate and the fluctuation range is small; the double chamber shakes the bag to clean the powder to ensure the continuous fluidization state.

● Graphical interface and PLC automatic control are adopted, the operation is simple, all operations can be completed according to the set parameters, and the process data can be recorded and printed for analysis.

Technical parameters

|

型号Model |

DPL-ⅡA |

DPL3/5 |

|

|

原料容器容积 Material Container |

顶喷top spray (L) |

9 |

18.5 |

|

底喷Bottom-spray(L) |

5 |

10 |

|

|

侧喷side spray (L) |

7.5 |

9 |

|

|

生产能力Capacity |

顶喷 top spray(Kg/batch) |

0.5-3 |

1.5-5 |

|

底喷Bottom-spray(Kg/batch) |

0.25-2 |

0.5-3 |

|

|

侧喷side spray (Kg/batch) |

0.5-2 |

1-2.5 |

|

|

压缩空气compressed air |

压力pressure Mpa |

0.4-0.6 |

0.4-0.6 |

|

耗量onsumption M³/min |

0.4 |

0.5 |

|

|

风机功率Blower Power Kw |

4 |

5.5 |

|

|

电加热功率Heating Power Kw |

4.5 |

12 |

|

|

外形尺寸Overall dimensions

|

长L(mm) |

1800 |

2250 |

|

宽W(mm) |

860 |

1050 |

|

|

高H(mm) |

2385 |

2850 |

|

|

直径diameter(mm) |

300 |

400 |

|

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025