Audited Supplier

Audited Supplier

In This Store

Category:Laboratory > Laboratory General Equipment > Drying equipment

Product Name:Chromatography column sieve plate

Price(USD):Negotiable

Company:SINTER FILTER TECHNIC CO.,LTD

Factory Location: Anping

Main Sales Markets: North America,Central/South America,Western Europe,Eastern Europe,Australasia,Asia,Middle East,Africa

Monthly Production Capacity: 12000 square meters

Packaging Information: wooden case

Delivery Lead Time: 20 days

Sample Provided: yes

Payment Terms: T/T

Type A Sintered Wire Mesh Summary

The product is a standard combination of Muti-layer sintered wire mesh which has the widest application. Five different layers of stainless steel wire mesh are combined as per corresponding structure, and then sintered together in the vacuum sintered equipment, compressed and calendered, forming a porous sintered material.

Type A Sintered Wire Mesh Material

The standard material are SS304, SS304L, SS316, SS316L. Special Alloy Steel :Hastelloy C-276, Monel 400, Inconel600, SS904, SS904L, Duplex steel 2205 are acceptable based on customer’s requirement.

Type A Sintered Wire Mesh Size

The standard size are 500×1000mm, 600×1200mm, 1000×1000mm, 1200×1200mm, 1200×1500mm, and special size in range can be finished as requirement.

Application of Type A Sintered Wire Mesh

1. Cylindrical Filter Element

It is widely applied in the filtration of liquid and gas. And it is applied in many industries, such as petrifaction, polyester, pharmacy, food and beverage and water treatment.

Moreover, the minimum diameter we can process can be up to 10mm and the filter rating can be up to 1micron.

In addition, as to the connection type and specification, we can produce it to the customer's request.

2. Filter Disc

It is mainly applied in drying and filtration in the pharmacy industry. The minimum diameter we can process can be up to 3000mm.And we can process it in split and integral type.

3. Catcher

It is mainly applied in pharmacy industry. It is used to intercept the powder particle in the dry gas and reduce the loss of the powder and air pollution.

In addition, because of the structure of the double tubes, it can increase the filter area in maximum.

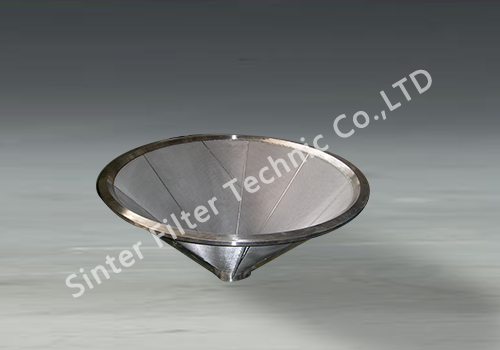

4. Conical Filter Element

It is mainly applied in chemical, pharmacy, and beverage industries. Due to the cone-shape, it can make the media get the better diversion, separation and filtration.

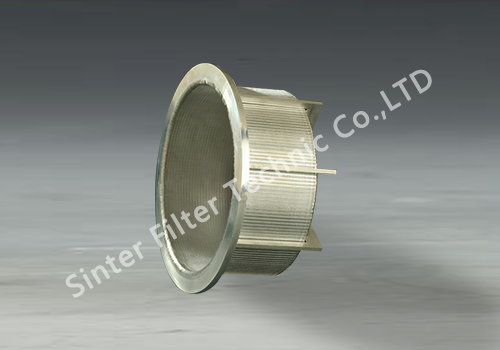

5. Centrifugal Clarifier

In order to make the media get effective filtration and separation, we process the sintered wire mesh into the rotary dynamic filter. And this filter is widely applied in chemical, pharmacy and food industries.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight June 2024: Globalization on the Go

Pharma Sources Insight June 2024: Globalization on the Go