Audited Supplier

Audited Supplier

In This Store

Category:API Equipment > Glass lining equipment

Product Name:6300L Glass Lined Reactor with Heating Cooling Jacket

Price(USD):Negotiable

Company:Shandong Tanglian Heavy Industry Group Co ., Ltd

Factory Location: Room 2414.Dingcheng buildina,Zhangdian Distrct,Zibo City,Shandong Province.china

Main Sales Markets: North America,Western Europe,Eastern Europe,Australasia,Asia

Packaging Information: less than container load ,full container load ,flat rack ,bulk cargo

Delivery Lead Time: 1months

Sample Provided: yes

Payment Terms: L/C

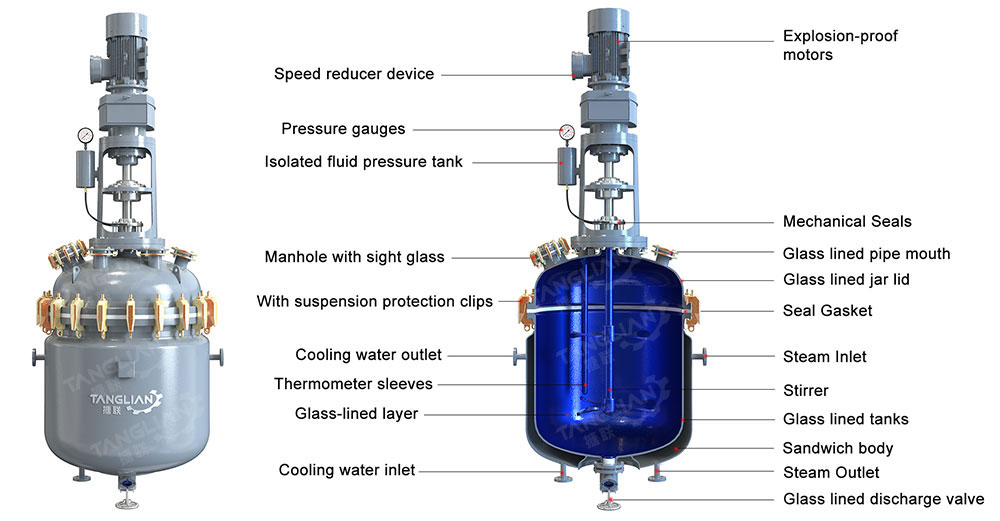

Glass lined reaction tank Introduction

Glass lined continuous stirred tank reactor,AE type glass lined reaction tank is a porcelain enamel rich in silica, lined on the inner surface of the steel vessel, and become a composite product by high temperature firing and firmly dense on the metal surface. Therefore, it has the double advantages of stability of glass and strength of metal, and is an excellent corrosion-resistant equipment. The AE type glass lined reaction tank is separated by body and cover, and connected by gasket and tank card in the middle, so it is easy to disassemble the open type, and if there is a problem with the pipe opening on the cover, it is easy to remove and repair separately.

Technical Parameters

|

INNER VESSE |

JACKET | |

| MATERIAL | Carbon Steel with Glass Linning | Carbon Steel |

| DESIGN PRESSURE(Mpa) | -0.1 / 0.6 | 0 / 0.6 |

| DESIGN TEMPERATURE(℃) | -19 / 200 | -19 / 200 |

| WORKING TEMPERATURE(℃) | -19 / 200 | |

| GLASS LINED THICKNESS(mm) | 0.8-2.0 | |

|

RESISTANCE TO SHARP TEMPERATURE VARIATION(℃) |

COOL SHOCK 110,HOT SHOCK 120 | |

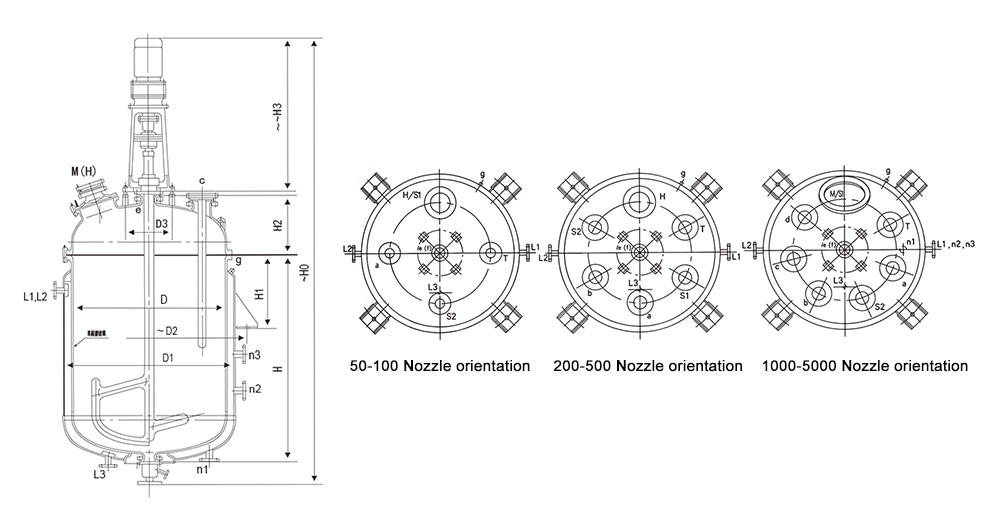

Main Dimensions of AE type glass lined reaction tank (50-5000L)

|

NOMINAL VOLUME (L) |

ACTUAL VOLUME (L) |

HEAT EXCHANGE AREA(m2) |

POWER (Kw) |

D (mm) |

D1 (mm) |

D2 (mm) |

D3 (mm) |

H (mm) |

H1 (mm) |

H2 (mm) |

H3 (mm) |

H0 (mm) |

WEIGHT (Kg) |

| 50 | 70 | 0.34 | 0.75 | 500 | 600 | 708 | 270 | 465 | 300 | 265 | 945 | 2030 | 445 |

| 100 | 127 | 0.84 | 0.75 | 600 | 700 | 826 | 270 | 565 | 320 | 300 | 945 | 2170 | 548 |

| 200 | 247 | 1.44 | 1.1 | 700 | 800 | 927 | 300 | 770 | 350 | 345 | 953 | 2440 | 649 |

| 300 | 369 | 1.75 | 3.0 | 800 | 900 | 1028 | 350 | 870 | 380 | 380 | 1154 | 2770 | 968 |

| 500 | 588 | 2.64 | 3.0 | 900 | 1000 | 1127 | 350 | 1070 | 400 | 405 | 1154 | 3030 | 1175 |

| 1000 | 1245 | 4.5 | 4.0 | 1200 | 1300 | 1461 | 400 | 1270 | 500 | 480 | 1276 | 3360 | 1803 |

| 1500 | 1714 | 5.2 | 4.0 | 1300 | 1450 | 1655 | 400 | 1470 | 650 | 505 | 1276 | 3326 | 2190 |

| 2000 | 2160 | 7.02 | 4.0 | 1300 | 1450 | 1655 | 400 | 1815 | 650 | 505 | 1276 | 3671 | 2450 |

| 3000 | 3237 | 8.61 | 5.5 | 1600 | 1750 | 1960 | 450 | 1810 | 700 | 580 | 1316 | 3791 | 3470 |

| 4000 | 4255 | 11.7 | 5.5 | 1600 | 1750 | 1960 | 450 | 2310 | 700 | 580 | 1316 | 4291 | 4018 |

| 4000 | 4340 | 10.9 | 5.5 | 1750 | 1900 | 2152 | 450 | 2025 | 700 | 620 | 1316 | 4046 | 4416 |

| 5000 | 5380 | 13.63 | 5.5 | 1600 | 1750 | 1960 | 450 | 2810 | 700 | 580 | 1316 | 4791 | 4568 |

| 5000 | 5340 | 13.8 | 5.5 | 1750 | 1900 | 2152 | 450 | 2485 | 700 | 620 | 1316 | 4508 | 5026 |

Nozzle Size of AE type Glass Lined Reactor (50-5000L)

|

NOMINAL VOLUME(L) |

M |

H |

e |

T1 |

S1 |

a |

b |

c |

d |

f |

n1-2 |

n3 |

L1-2 |

| 50 | - | 80 | 70 | 70 | 70 | 70 | - | - | - | 70 | - | - | 20 |

| 100 | - | 80 | 70 | 70 | 70 | 70 | - | - | - | 70 | - | - | 20 |

| 200 | - | 125 | 80 | 70 | 70 | 80 | 70 | - | - | 80 | - | - | 25 |

| 300 | - | 125 | 100 | 70 | 70 | 80 | 70 | - | - | 80 | - | - | 25 |

| 500 | - | 150 | 100 | 70 | 80 | 100 | 125 | - | - | 80 | - | - | 32 |

| 1000 | 300×400 | - | 125 | 100 | 100 | 100 | 125 | 100 | 100 | 100 | - | - | 32 |

| 1500 | 300×400 | - | 125 | 100 | 125 | 100 | 125 | 100 | 125 | 100 | 50 | - | 40 |

| 2000 | 300×400 | - | 125 | 100 | 125 | 100 | 125 | 100 | 125 | 100 | 50 | - | 40 |

| 3000 | 300×400 | - | 125 | 100 | 125 | 100 | 125 | 100 | 125 | 125 | 65 | - | 50 |

| 4000 | 300×400 | - | 125 | 100 | 125 | 100 | 125 | 100 | 125 | 125 | 65 | - | 50 |

| 4000 | 300×400 | - | 125 | 125 | 125 | 125 | 150 | 125 | 125 | 125 | 65 | 65 | 70 |

| 5000 | 300×400 | - | 125 | 100 | 125 | 100 | 125 | 100 | 125 | 125 | 65 | - | 50 |

| 5000 | 300×400 | - | 125 | 125 | 125 | 125 | 150 | 125 | 125 | 125 | 65 | 65 | 70 |

Glass Lined Reactor Process Flow

Glass lined continuous stirred tank reactor Advantages

● For small, medium and small scale chemical and pharmaceutical production.

● The lid can be separated from the tank, and a variety of stirrer types can meet the different process needs of users.

● After removing rust on the surface of the chemical reactor, spraying environmental protection water-based paint makes the product more beautiful and environmental friendly.

● Comply with ASTM, ASME, CE, CN standards

● Various non-standard capacities can be designed and customized according to customers' requirements.

Factory Scenes

Company Products

Shipping & Installation

International Market

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight June 2024: Globalization on the Go

Pharma Sources Insight June 2024: Globalization on the Go