PharmaSourcesJanuary 02, 2024

Tag: Supply , API Drug , Markets

Active pharmaceutical ingredients, also known as APIs, refer to the biologically active components of drugs that provide pharmacological activity or direct action. APIs are generally synthesized chemically or extracted from biological sources and comprise the therapeutic moiety of pharmaceutical formulations. As pharmaceutical drug manufacturing has become a global endeavor, API production must adhere to internationally recognized standards of quality, safety, and efficacy. With API drug ingredients often being sourced from facilities around the world, the need for clear and consistent regulations across jurisdictions is of utmost importance.

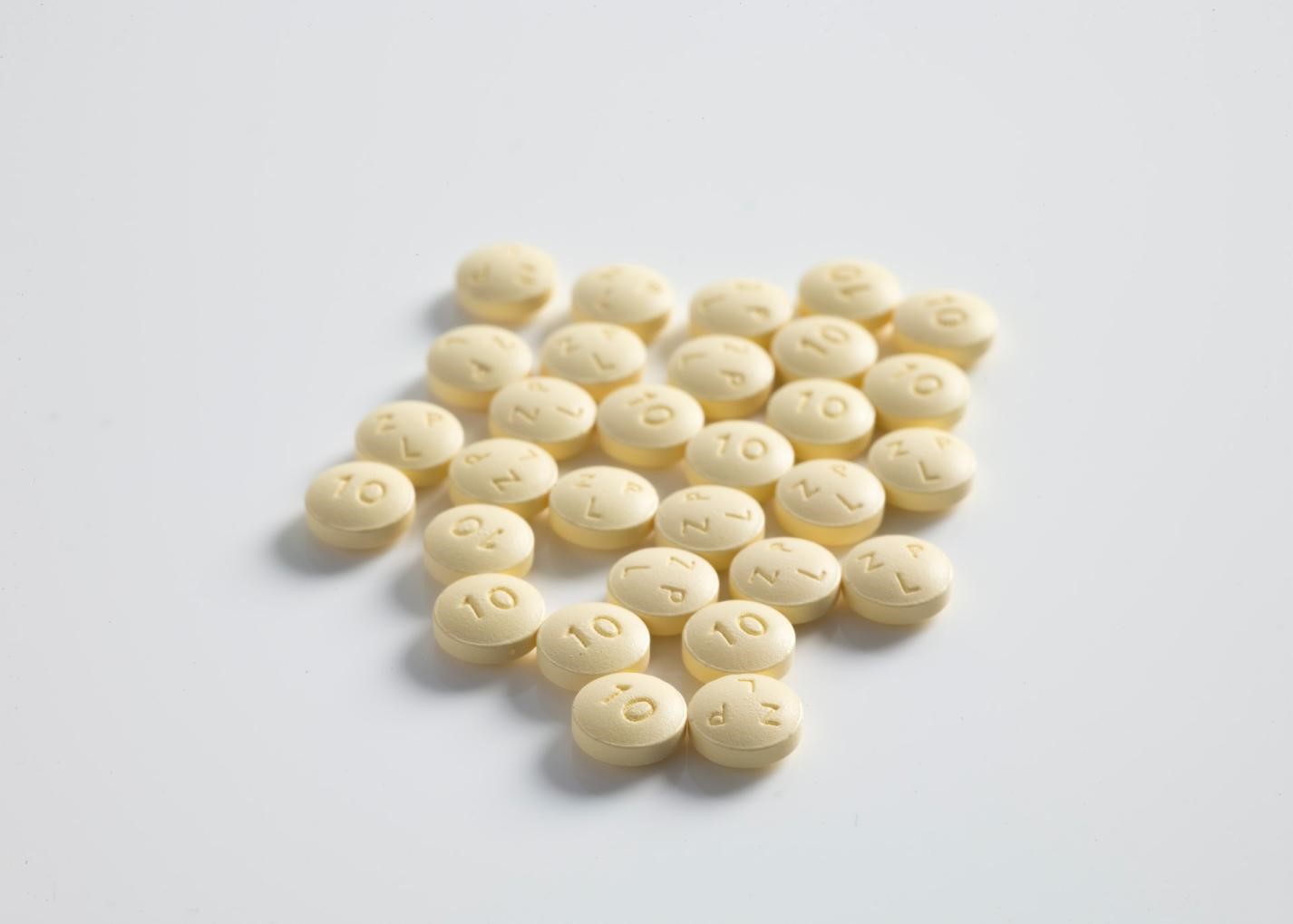

Photo by Thought Catalog on Unsplash

Different pharmaceutical markets around the world have established distinct API regulatory frameworks to govern API drug production. Three major pharmaceutical markets include the United States, the European Union, and India. They demonstrate both similarities and differences in their regulatory oversight.

In the United States, the Food and Drug Administration (also known as FDA) regulates APIs and ensures their quality, safety, and effectiveness. It sets manufacturing standards through its Current Good Manufacturing Practice (cGMP) guidelines, conducts facility inspections, and approves New Drug Applications, which must include data on the API. APIs produced domestically or imported into the U.S. must adhere to these cGMP standards throughout the product lifecycle, from synthesis and testing to packaging and labeling.

Current Good Manufacturing Practice (cGMP) standards provide a quality system approach to API drug manufacturing by establishing procedures, processes, documentation, and pharmaceutical labeling requirements. cGMP guidelines cover quality control operations and quality assurance measures.

Regulatory pathways for new API approvals in the U.S. include the Drug Master File (DMF) approach, which allows for confidential API information to be submitted directly to the FDA. Oversight aims to promote quality throughout the supply chain from initial manufacturing to final drug products.

The European Medicines Agency (also known as EMA) is responsible for the centralized authorization and supervision of human drugs in Europe through its Committee on Herbal Medicinal Products. The EMA adheres to the European Pharmacopoeia, which outlines quality standards for APIs and dosage forms. Pharmaceutical companies seeking to market medicinal products within Europe must submit dossiers demonstrating quality, efficacy, and safety.

The European Pharmacopoeia provides binding quality standards for APIs, including monographs on identity tests, assays, and related substance limits. These standards aim to protect public health across Europe.

The EMA has also implemented Mutual Recognition Agreements (MRAs) with stringent API drug regulatory authorities in third countries like the U.S., Canada, Australia, Israel, New Zealand, Switzerland, and Japan to streamline approval pathways based on reliance and data-sharing between agencies. MRAs are an example of regulatory cooperation that minimizes duplication.

India's Central Drugs Standard Control Organization (CDSCO) operates under the Ministry of Health and Family Welfare. CDSCO regulates pharmaceuticals through statutes like the Drugs and Cosmetics Act. It oversees licensing of facilities and inspects to ensure compliance with manufacturing standards.

The Drugs and Cosmetics Rules' Schedule M outlines the minimum requirements for GMP-compliant manufacturing of APIs. These requirements mirror ICH Q7 guidelines, which provide the quality standards for API drug manufacturing by defining the aspects of GMP that apply to APIs. Regular audits and assessments are conducted by CDSCO to verify adherence to these good manufacturing practices and GMP standards.

Photo by Volodymyr Hryshchenko on Unsplash

Effective quality control and assurance measures are essential for API drug manufacturers to achieve and ensure regulatory compliance. Comprehensive and rigorous quality systems help identify issues and ensure customer safety.

Analytical techniques and testing protocols play an integral role in quality evaluation. Analyzing raw materials and samples during production requires the detection of potency, purity, and related substances by means of analytical techniques like high-performance liquid chromatography and gas chromatography-mass spectrometry. Tests for identification and strength provide crucial information on API quality attributes.

Quality risk management is another important aspect of maintaining high API drug production standards. Identifying potential quality risks from raw material variability, equipment issues, or human errors can be done through tools like failure mode and effects analysis. Risk levels are then evaluated and appropriate controls are established to prevent, monitor, or mitigate these risks. Continuous risk assessments help facilities proactively address potential issues and ensure patient safety. Periodic management reviews further ensure these quality risk management strategies remain effective over the long term.

Image by Freepik

In today's interconnected pharmaceutical industry, achieving consistent quality and regulatory standards across international supply chains is critical. Companies producing API drugs must comply with rigorous oversight to ensure public health protection.

For over a decade, PharmaSources has connected global buyers with top pharmaceutical suppliers through insightful market data and partnership opportunities, engaging our community of 145,000+ active members. We seamlessly support companies seeking to expand or optimize sourcing. The collaborative guidance we offer provides strategic advantages to companies committed to quality progress in this evolving field. Visit PharmaSources' online web portal today to learn more about what makes us a valuable industry partner for pharmaceutical companies in the global pharma marketplace.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025