Shruti TalashiMay 16, 2023

Tag: GMP , cGMP , Pharmaceutical , generics , biosimilar

When we read Pharmaceuticals, the initial term that comes to our mind is ‘drugs’. And of course Pharmaceuticals as a build-up infrastructure for manufacturing makes drugs as medicines only. As per the Food and Drug Administration (FDA) organization there are more than 32,000 approved generic drugs in the global market. Licensed generic drugs are sold over the counter (OTC) in a pharmacy based on physician’s prescription. Some examples of OTC drugs are such as aspirin e.g. Paracetamol (fever), Combiflam (for fever & as a pain killer) etc., anti-histamine e.g. Citrezin, Allegra etc. or antibiotics e.g. penicillin, amoxicillin (bacterial and fungal infection) etc.

Apart from the generic medicines we have biologics, these are most appropriately considered as lifesaving drugs since these have been a flair out of the scientific research in the fight against genetic diseases such as hypertension, diabetes etc., cancer e.g. breast cancer, prostate cancer, ovary cancer etc. , autoimmune diseases such as rheumatoid arthritis, sexually transmitted diseases e.g. AIDS, HPV etc.

Biologics are not the same as generic medicines based on the production. Generic medicines has active compound (molecules) that is produced via chain of complex chemical reactions in lab/industry but biologics are made from the cells, used as tissues, contain components of cells, blood components so these are macromolecules much complex and bigger than the drugs. There are over 620 licensed biologic as medicines in market this includes vaccines such Hepatitis-B, Yellow fever, CoVAXIN (CoVID-19) etc., monoclonal antibodies e.g. Herceptin, Avastin etc., hormones e.g. insulin, progesterone, vitamin-D etc., immune modulator e.g. abatacept & others. The process of manufacturing of the generic drugs and biologics are not the same as generic drugs are known to be manufactured in bulk but this is not the same for the biologics nevertheless the demand of biologics are increasing but since the use of cutting edge technology in making of the biologics so it make it deem for biopharmaceuticals to have reliable and agile forecast predicting the demand in the market in coming years.

There is a term as Biosimilars being used quite these days, this should not be confused with the term biologics. The biosimilars drug has a reference drug which is the biological medicine. Biosimilar mimics the biological medication/Biologics with a certain difference in the overall structure of the active macromolecule (proteins) so it is clear that we cannot replace the word as biosimilars with biologics.

In much simpler way we can say that ‘Generic drugs are manufactured in Pharmaceuticals and Biological medicines are manufactured in Bio-pharmaceuticals.’ Indeed the Pharmaceuticals industry is not the same as Bio-pharmaceutical industry and the major difference lies in the approach of manufacturing the medicine. Bio-pharmaceutical industry would cost much times than Pharmaceutical industry since this former is based on the biotechnology that involves use of cutting edge technology for producing lifesaving drugs.

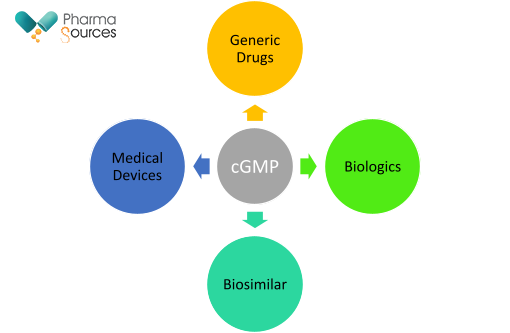

Be it a pharmaceutical or bio-pharmaceutical, both are regulated by the FDA, US. And it is mandatory for both kinds of manufacturing companies to follow the current Good manufacturing practices (cGMP) inprocess of getting certified from USFDA. Presently, most of the drug making companies are following the Good manufacturing practices yet the drugs produced in these pharma companies are considered as ‘adulterated’ by USFDA unless they meet cGMP.

Above flow diagram is showing as cGMP is applied to medicine/ medical devices used in healthcare sector

To being with as Good manufacturing practices (GMP) is a system that consists of documentation, training, and standard procedures that are essentially to be followed in manufacturing units to ensure that the quality drugs are consistently produced in a controlled manner. These practice helps in easy identifying of any deviation and with corrective & preventive action method the standard procedures are modified, also by following it the companies could cut down on losses and waste, protect individual’s life, avoid re-calls avoid seizure, fines and jail time. There are five main components of the GMP known as 5 P’s including people, product, processes, procedure & premises. Without workforce the manufacturing unit will not be running the production hence it is important to have training and assessments modules in place for employees such that they fully understand their role and responsibility. Product as dugs manufactured should be undergo consistent testing from raw material to finished goods to holding in chambers for stability study as the manufacturer has to ensure that the active pharmaceutical ingredient is having the clear specifications at every phase of production. This data on product testing at various phases are kept by the quality assurance department for assessments, regulatory audits and export marketing use. Processes should be clearly defined to the employee and regular evaluation should be conducted to ensure that all employees are complying with the current processes and are gathering the essential standards of the organization. Procedures are set standards that should be followed by the drug analyst while performing analytical testing methods and any deviation in the procedure should be reported immediately and investigated by the subject matter expert. The investigation should be closed within the timeframe and CAPA should be implemented such that this incidence does not repeat again. Premises should have signs to promote cleanliness, encourage to follow lab safety and safety exists. All the equipment’s should be placed and stored properly and calibrated at defined interval of time to avoidin consistency in the analytical test results and prevention of equipment failure. cGMP includes all above components but demands from the pharma manufacturing industries to maintain auditable electronic signature for processes and procedures and not reply on paper records. As defined in the CFR 21 11.200 e.g. at a single point of time only one signature shall be executed as electronic signature by the employee. cGMP requires cost to automate the processes and procedure involved in manufacturing by investing in quality management systems that will store all the data in cloud server this way the manufacturing unit will be ready for site visit at any point of time. As per US FDA, to achieve cGMP all existing manufacturing firms should keep their processes and procedures updates and allied with the code of federal regulation that are available online at www.fda.gov . By switching to electronic quality management system (eQMS), the manufacturing industries can achieve greater success in maintaining the quality of the drug, getting better revenue and being always prepared for audits. Not only that, in order to export the drugs internationally, the USFDA accreditation is essential for any pharma industry so by having electronic signature of documentation companies that are currently running on conventional methods could save a lot of time. There are many benefits in having eQMS, this will help in sustainability and lowering the carbon foot printing e.g. going paperless & bank on auditable electronic signature more and more. There are numerous challenge for the existing pharma companies while achieving cGMP naming from limitation in funding, less workforce, limited resource availability, lack of management and roadmap but it is very crucial to keep the GMP in check always with ensuing the safety of manufactures process with help of timely internal audits reports without predisposition.

It comes at a great responsibility for every pharma units around the globe be is small or huge while using resources they need to minimize the errors with risk assessments e.g. consistently reviewing of standard operating procedures along with people’s training & knowledge assessment. In conclusion, above discussion has most discussion on GMP that might interest reader’s to learn more about cGMP’s necessity and requirement in any and every drug manufacturing unit working rigorously by contributing to improve and benefit the health sector.

1) https//www.fda.org

2) Google search

3) Above writing is collective experience of working as apprentice quality control officer in a pharma manufacturing unit based in India. During the period, manufacturing unit had been undergoing various regulatory audits and the USFDA visit.

Ms. Shruti Talashi boasts a dual mastery of lab research and writing. Her doctoral study outcome as M.Phil in biomedical science while studying breast cancer and an extraordinary masters degrees dissertation work on exploring role of Gal-lectin in cancer metastasis fuels her extensive research interests. She has gained few publication in journals. Bridging the science-public gap is her passion, aided by expertise in diverse techniques. From oncology to antibiotic/drugs production, she's led and managed complex projects, even clinical trials. Now, as a freelance Content Coordinator for Sinoexpo Pharmasource.com, her industry knowledge shines through valuable insights on cutting-edge topics like GMP, QbD, and biofoundry.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025