Give us details about the solution that you have launched recently for vaccine delivery across India to aid the COVID-19 vaccination drive.

Tessol took up the challenge to build products for the safe transportation of vaccines at the beginning of the pandemic. We have all the required expertise and technology in-house to build these solutions that we believed will be critical for the large-scale rollout of the vaccine.

We tied up with Koolex logistics, the largest pharma trucking company in India and built solutions for long-distance and last-mile movement of pharma products.

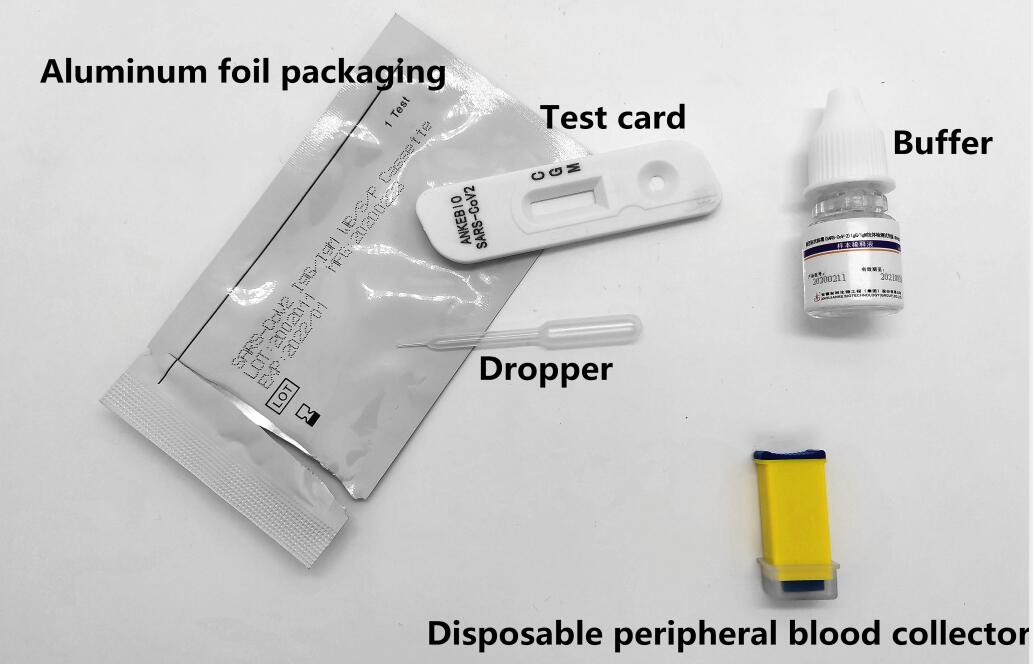

Our products cover all temperatures from -20 degrees Celsius (required for Moderna and Sputnik V vaccines) to two-to-eight degrees Celsius required for other vaccines like Covaxin and Covishield. We have already validated our solutions with several pharma companies and logistics players. In order to facilitate the industry, we have also opened our doors to sell the Phase Change Material (PCM) – our core technology – product to companies engaged in making cold-chain solutions, especially for the pharma industry.

What made you take this step and for how long have you been doing this?

We have launched the vaccine delivery solution keeping in mind the massive ongoing drive in India to inoculate each and every Indian. The entire world is facing a challenging situation. due to the ongoing pandemic.

Therefore, vaccinating the maximum number of people in the country is the only way to halt the ongoing growth in infection. Tessol is contributing its bit by launching vaccine delivery solutions for pharma companies, logistics companies and organisations. With the help of our technology, we are supporting this huge cause of vaccinating many Indians.

As of now, how many areas/small towns/cities/states have you catered to? Kindly name these and also tell us about the contribution that you have made there.

Tessol is present in all major cities in India like Mumbai, Bengaluru, Delhi, Chennai, Cochin, Coimbatore, Ahmedabad, Pune, Nagpur, Hyderabad and many others.

With over 500 vehicles and 300 home-delivery units in operation, our solutions cater to clients on a pan-India basis. Our greatest contribution has been in making the last-mile cold chain viable and reliable for our customers. Given the nature of the last-mile retail and home delivery market, the cold chain is invariably not viable for most customers forcing them to either break the cold chain or rely on unsafe options such as dry ice.

Customers who do not wish to do either, choose not to cater to the segment. We have effectively addressed this problem by enabling our customers to not only expand their reach, but by also ensuring that product quality and safety are not compromised till the last delivery point.

What are the major challenges faced by the Indian supply chain when it comes to delivering pharmaceutical products to the last mile and what immediate steps must be taken to overcome these?

In my view, the biggest challenge in the supply chain in India is the viability, given low price points. In many cases, it is cheaper to waste the product than to save it. Harsh but true.

We see this not only in commodities like food and vegetables, liquid pouch milk, etc., but also in frozen food, etc. at the last mile. Even if the product has a high price point, given the scenario of fragmented retail fabric in India, the throughput to one location or shop is small, and even the smallest refrigerated vehicle is too big for carrying that load.

Therefore, there is a tremendous price pressure on the cold-chain operators while the basic cost is fixed with the minimum CAPEX and OPEX (especially with increased diesel prices). In most cases, they end up subsidising the local movement through storage or use unorganised players who have limited cold chain experience.

Briefly explain the solutions built by Tessol for long-distance and last-mile movement of pharma products.

Tessol solutions allow pharma companies/logistics providers to offer end-to-end transportation of vaccine packages from source to end customers without breaking the cold chain up in a highly temperature-controlled environment.

The company’s proven thermal battery and technology provides the desired temperature control (from -25 degrees Celsius to +25 degrees Celsius) across enclosures ranging from a five-litre bag to 20-feet (10 ton) truck. Its core technology uses proprietary PCM heat exchangers and chargers that store thermal energy (therefore, the term thermal battery) and releases it as required during the transport period.

How do you intend to expand your business in the next five years?

We realise that we are on the cusp of tremendous growth. We have the full technology stack required for building this business, along with some large wins on the customer end. Our core value and application spread built during the last eight years is beyond what most of the matured companies will be able to build, especially given our limited resources. The value proposition and product market fits have been established and even the products have matured.

We have active partners in Dubai, African Continent, Sri Lanka and New Zealand. We also have 25 active Tamsys units running in New Zealand and have powered the country’s first zero-emission refrigerated van. We also partnered with Tata to supply the first PCM-based ice cream truck in Mozambique. Further, our bike delivery solutions have been used in Dubai by our partners.

While we are already investing in growing our capacities, at this point in time, we are also actively looking at investments and strategic partnerships that can help scale our technology and solutions to a global level. It is no longer a small play that we are sitting on – our solution is critical for the growth of pharma and food retail not only in India, but globally. The incoming demand from overseas is an evidence of that.

ALL

ALL Pharma in China

Pharma in China Pharma Experts

Pharma Experts Market News

Market News Products Guide

Products Guide Brand Story

Brand Story

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025