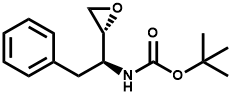

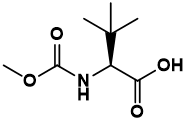

Aurinia Pharmaceuticals and Lonza have expanded their exclusive manufacturing relationship. The parties entered into a collaborative agreement to build a dedicated manufacturing capacity within Lonza’s existing small molecule API facility in Visp, Switzerland. The dedicated facility, also referred to as "monoplant," will be equipped with state-of-the-art manufacturing equipment to provide cost and production efficiency for the manufacture of voclosporin, while expanding existing capacity and providing supply security to meet future commercial demand.

The new agreement builds on the parties' successful multi-year relationship. The agreement, which is conditional on regulatory approval of voclosporin, does not impact the launch supply for voclosporin as this is secured by existing capacity. The monoplant is estimated to be operational in 2023.

“This collaboration is a great example of how we can support both early and commercial-stage biopharmaceutical companies through innovation in manufacturing technology and flexible business models,” said Gordon Bates, president small molecules division, Lonza. “We are looking forward to further developing our relationship with Aurinia into a long and productive collaboration to supply this innovative medicine to patients across the globe.”

Following U.S. regulatory approval of voclosporin, Aurinia will commence several capital expenditure payments. Upon completion of the monoplant, Aurinia will have the right to maintain unobstructed use of the monoplant by paying a quarterly fixed facility fee.

The U.S. Food and Drug Administration (FDA) accepted the filing of Aurinia’s NDA for voclosporin in the treatment of lupus nephritis (LN), granted Priority Review, and assigned a Prescription Drug User Fee Act (PDUFA) target action date of January 22, 2021.

Peter Greenleaf, president and chief executive officer, Aurinia Pharmaceuticals, said, “Lonza’s world-class expertise and partnership have helped Aurinia to cost-effectively optimize the unique and complex manufacturing process required for the synthesis of voclosporin. We are currently well-poised and ready with adequate product supply for launch and anticipated market demand. A dedicated production capability will help keep our manufacturing costs down and ensure long-term flexibility to meet future demand for years to come.”

ALL

ALL Pharma in China

Pharma in China Pharma Experts

Pharma Experts Market News

Market News Products Guide

Products Guide Brand Story

Brand Story

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025