Tim FreemanJune 26, 2019

Tag: Freeman Technology , Tim Freeman , Powder Flow , storage , Handling

When working with powders, in-process performance and final product quality will be influenced by properties of the raw materials delivered to the process. The ability to control these raw materials, and therefore reliably predict process performance, is essential to ensuring the properties and quality of the final product. A method of accurately measuring process-relevant properties of incoming raw materials is therefore highly beneficial to a wide range of applications in various industries. This application note considers the evaluation of bulk excipients for tableting and the impact of storage and handling conditions.

Variations in Process Performance and Product Quality

Sorbitol was used as the bulk excipient in production of a tablet. The tablet manufacturer experienced variation in final product quality when using two batches of sorbitol that had previously been categorised as identical by the supplier. Tablets produced from one batch were consistently softer and less stable than those from the other batch. Following further investigation at the customer’s request, the excipient supplier was unable to differentiate between the batches using techniques they had available.

The only difference identified recorded about the batches was the location in which they had been stored before being supplied to the customer: the well-performing batch was stored in a silo close to the loading area (Silo 1), and the poorly-performing batch in a Silo further away (Silo 2), necessitating additional conveyance prior to processing.

Samples from both batches were analysed using an FT4 Powder Rheometer®.

Test Results

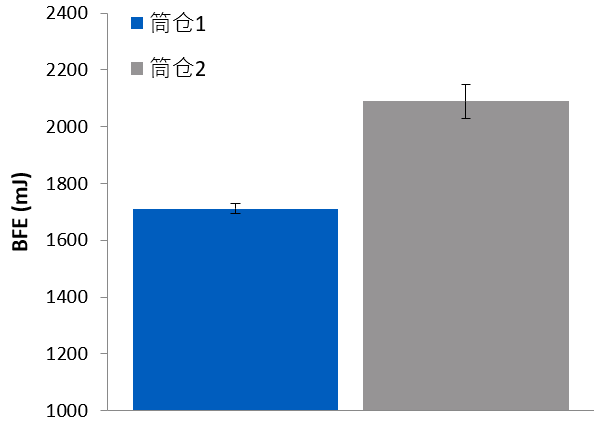

Dynamic Testing: Basic Flowability Energy

The sample from Silo 2 generated a higher Basic Flowability Energy (BFE) than the sample from Silo 1. This indicates that it was more resistant to dynamic flow in a confined space (such as in a screw conveying or mixing process) requiring more energy to achieve the same outcome.

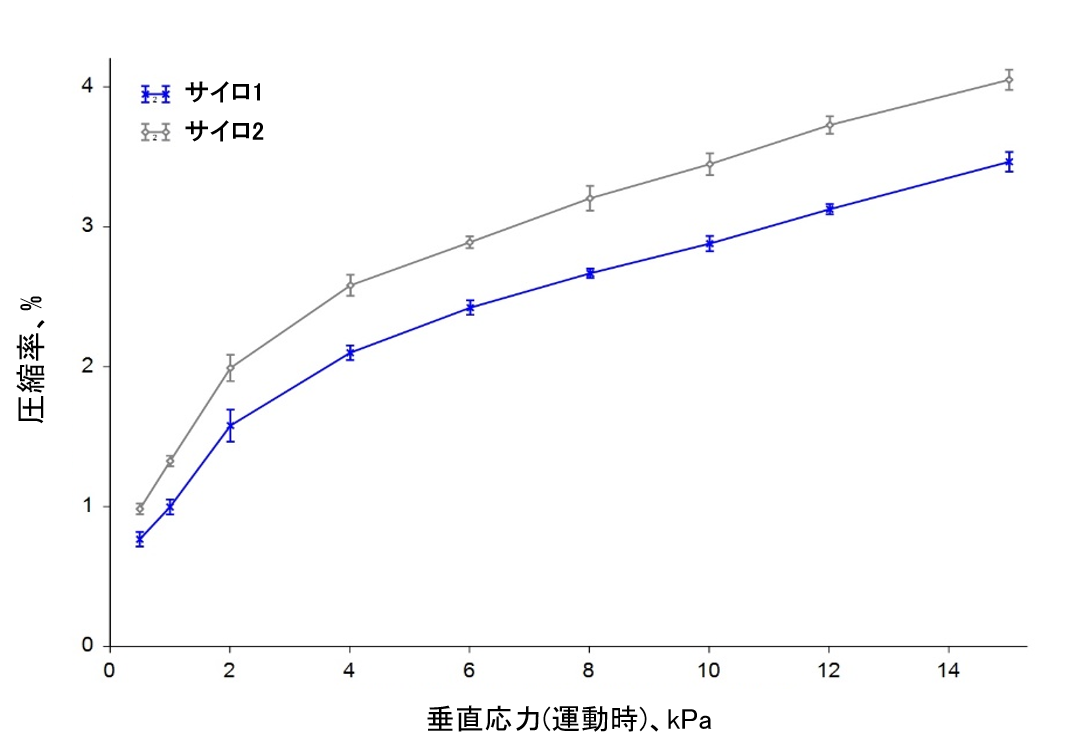

Bulk Testing: Compressibility

The sample from Silo 2 was more compressible than the sample from Silo 1, indicating that it entrained a greater proportion of air within its bulk, which is typically a property of more cohesive powders. Higher Compressibility can contribute to poorer behaviour in processes where a powder is subjected to an applied force, such as in mechanical feeders or tablet presses, or simply as a consequence of storage in large quantities.

Bulk Testing: Permeability

Similarly, the sample from the Silo 2 generated a higher Pressure Drop across the Powder Bed under a constant throughput of air, indicating that this sample was less permeable than the sample from the Silo 1. Low permeability can contribute to poor performance in operations where a powder is required to release entrained air, such as die filling and tableting, and can adversely impact gravitational flow in general.

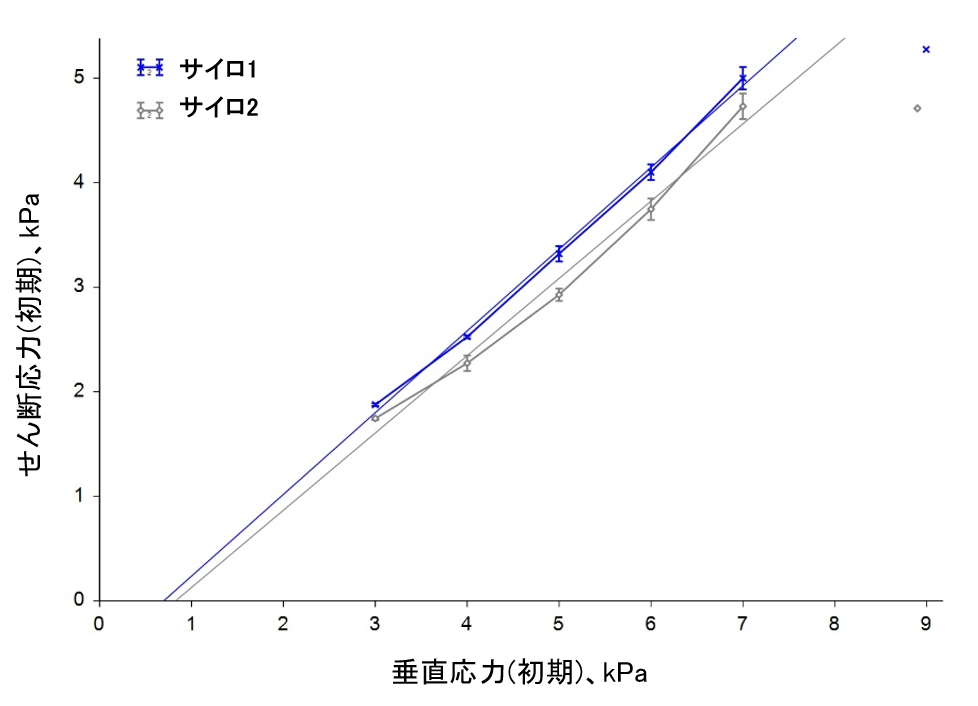

Shear Cell Testing

Counter-intuitively, the sample from Silo 2 generated slightly lower Shear Stress values following consolidation at 9 kPa than the sample from Silo 1. This suggests it would more readily transition from a static, consolidated state in to a state of flow, such as when required to flow from a hopper. This illustrates how Shear Cell test results may not always be most relevant as the test conditions do not represent what the powder is subjected to in process. Even when evaluating hopper flow, shear properties alone may not fully describe performance, as Permeability is also known to be influential.

The yield loci for the two samples are non-linear and suggest that the powder from Silo 2 may generate higher Shear Stress values at lower levels of consolidation. Furthermore, due to the location and shape of the yield loci, Mohr circle’s analysis of the data could not be completed as a linear best fit line intercepts the y-axis below zero.

Conclusions

The FT4 has identified clear and repeatable differences between two very similar materials that performed differently in a process. The sample from Silo 2 demonstrates a greater resistance to forced flow (higher BFE), higher Compressibility and lower Permeability, which are all indicators of greater cohesivity. This information could be used to screen raw materials in order to identify those that are suitable for processing and those that are likely to be problematic. Furthermore, the results demonstrate that Shear Cell testing alone may not provide a reliable representation of powder behaviour in this process, due to the differing stress and flow regimes present.

Powder flowability is not an inherent material property, but is more about the ability of powder to flow in a desired manner in a specific piece of equipment. Successful processing demands that the powder and the process are well-matched and it is not uncommon for the same powder to perform well in one process but poorly in another. This means that several characterisation methodologies are required, the results from which can be correlated with process ranking to produce a design space of parameters that correspond to acceptable process behaviour. Rather than relying on single number characterisation to describe behaviour across all processes, the FT4’s multivariate approach simulates a range of unit operations, allowing for the direct investigation of a powder’s response to various process and environmental conditions.

Author Biography

Tim Freeman, Managing Director, Freeman Technology

Tim Freeman is Managing Director of powder characterisation company Freeman Technology for whom he has worked since the late 1990s. He was instrumental in the design and continuing development of the FT4 Powder Rheometer® and the Uniaxial Powder Tester. Through his work with various professional bodies, and involvement in industry initiatives, Tim is an established contributor to wider developments in powder processing.

Tim has a degree in Mechatronics from the University of Sussex in the UK. He is a mentor on a number of project groups for the Engineering Research Center for Structured Organic Particulate Systems in the US and a frequent contributor to industry conferences in the area of powder characterisation and processing. A past Chair of the American Association of Pharmaceutical Scientists (AAPS) Process Analytical Technology Focus Group Tim is a member of the Editorial Advisory Board of Pharmaceutical Technology and features on the Industry Expert Panel in European Pharmaceutical Review magazine. Tim is also a committee member of the Particle Technology Special Interest Group at the Institute of Chemical Engineers, Vice-Chair of the D18.24 sub-committee on the Characterisation and Handling of Powders and Bulk Solids at ASTM and a member of the United States Pharmacopeial (USP) General Chapters Physical Analysis Expert Committee (GC-PA EC).

-----------------------------------------------------------------------

Editor's Note:

If you have any suggestion to the content,

please email: Julia.Zhang@ubmsinoexpo.com

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025