Pharmaceutical manufacturing has traditionally been performed using batch process techniques. Batch processes have been proven over many decades of use, but can have shortcomings when it comes to efficiency, quality control, and safety. For many years, the U.S. Food and Drug Administration (FDA) has encouraged manufacturers to consider the benefits of new technologies. With increased pressure on quality and costs, and more stringent environmental and safety regulations in place, many manufacturers are considering the benefits of flow chemistry and continuous flow manufacturing.

Flow chemistry: an inherently safer, more efficient and cost-effective alternative

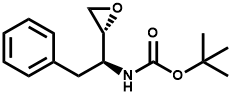

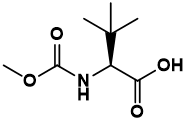

Flow chemistry involves the continuous flow of process chemicals through tubes or channels and avoids common difficulties encountered in producing pharmaceutical intermediates by batch manufacturing. In a continuous flow application, two or more reagents are continuously supplied into the reactor which then react to produce the required chemical. The chemical manufacturing industry is increasingly looking to continuous flow processing as a less risky, more efficient, and less costly alternative to traditional batch processing.

Continuous manufacturing reduces space requirements, increases safety and reliability, while also improving process understanding and control. It also enables process intensification (smaller space requirements, better heat transfer, less waste), larger reaction space and telescoping of reactions, steady operation with process analytical techniques (PAT), process automation, on-line optimization, risk reduction and increased plant productivity.

FDA initiatives call for continuous improvement to minimize risk and streamline pharmaceutical manufacturing

Federal regulatory agencies have long supported the use of continuous flow chemistry in pharmaceutical manufacturing. Beginning in 2002, the FDA launched an initiative entitled "Pharmaceutical CGMPs for the 21st Century: A Risk-Based Approach," to encourage the implementation of a modern, science- and risk-based pharmaceutical quality assessment system. One goal of the initiative is to ensure that regulatory review, compliance, and inspection policies maintain support of continuous improvement and innovation in the pharmaceutical manufacturing industry. Since publication of that initiative document, the FDA has promoted a vision of a maximally efficient, agile, flexible pharmaceutical manufacturing sector that reliably produces high-quality drug products without extensive regulatory oversight.

More recently, the FDA announced[1] in 2018 that the Agency is "committed to supporting and enabling pharmaceutical innovation and modernization as part of the Agency’s mission to protect and promote public health". The FDA hopes that these efforts may also help reduce the number of drug shortages, as noted in the Agency’s drug shortage strategic plan.

In recent draft guidance[2], the FDA stated that the adoption of continuous flow manufacturing is a foundation for improving the overall quality and availability of products for patients. The guidance further stated that "continuous manufacturing can improve pharmaceutical manufacturing by using an integrated process with fewer steps and shorter processing times; reducing the equipment footprint; supporting an enhanced quality by design (QbD) development and use of process analytical technology (PAT) and models; enabling real-time product quality monitoring; and providing flexible operation to accommodate changing supply demands." The FDA also expects that this operational flexibility may decrease the need for some post-approval regulatory submissions. Therefore, the FDA anticipates that adoption of continuous manufacturing for pharmaceutical production will reduce quality issues in the manufacturing of drug products, lower manufacturing costs, and increase availability of quality medicines to patients.

Corning’s reactor technology: driving innovation in chemical manufacturing

Corning Incorporated, a company with a 167-year history, has a long track record of working with industry leaders to enhance products and product manufacturing processes. Corning® Advanced-Flow™ Reactors (AFR) are high-throughput, easily scalable reactors that enable cost-effective solutions for a wide range of reactions in continuous flow chemistry applications. Every reactor in the AFR product line is built around the same fundamental component – the integrated fluidic module, a meticulously engineered reactor plate made of either glass or silicon carbide – which allows for rapid and seamless scale-up from lab scale to commercial production.

ALL

ALL Pharma in China

Pharma in China Pharma Experts

Pharma Experts Market News

Market News Products Guide

Products Guide Brand Story

Brand Story

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025