Overview of the Company

As a Japanese-owned enterprise invested and established by Japan Alps Pharmaceutical Ind. Co., Ltd. and Japan Longtai Trading Co., Ltd. on August 30, 1994, Qingdao Tai Tong Pharmaceutical Co., Ltd. now has registered capital of USD 6.75 million, and actual aggregate investment of USD 15 million.

The company is in northern Qingdao, China and by the side of the Yellow Sea, only 5km from Qingdao Airport where the lines reach every part of the world; it only takes 30min for the company’s goods to reach Qingdao container terminal from which the goods can directly reach each European and American base port.

The company is the largest manufacturer of rutin in the world, which has been produced for above 66 years since first produced in Japan in 1951. During the period, the company’s “Rutin” brand has achieved stable and long-term development thanks to the support and consideration of the new and old customers from China and foreign countries. The company started to conduct formal production and operation as the largest and most advanced professional manufacturer of rutin in China since April 26, 1996 after over 1 year of construction in Qingdao, China.

The company faces the world market based on the rich medicinal materials and plant resources in China and depending on the advanced extractive technique and management level, and has achieved much development in recent years, from originally the professional manufacturer of rutin APIs to a comprehensive plant extract manufacturer of APIs, food additives, pharma intermediates, and cosmetics raw materials.

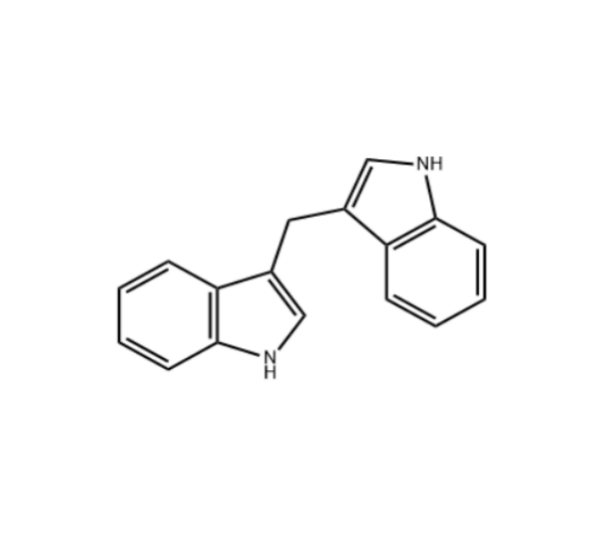

Rutin—With raw material from natural ingredients of the natural plant Chinese scholar tree, rutin is produced upon extraction and refinement. The company has established stable raw material supply channels in China and Vietnam over the years, to guarantee the stability of rutin production. Rutin can contract capillaries, can be used in hemostatic, can be used to treat and prevent cerebral hemorrhage and hypertension, and can also be used in pharmaceutical products and health products for diseases of capillaries. Experimental research in recent years has discovered that it can also be used in sunscreen cosmetics. The product of the company is mainly used as raw material of water soluble rutin, and sold to European countries and Japan.

The company can produce 500 tons of rutin every year, with large extracting devices working continuously for 24h to handle over 10 tons of raw materials every day. The product has been scientifically verified for years, and is produced through extraction →filtration →concentration →crystallization →centrifugation →drying →smash →mixing →packaging, etc. Processes from centrifugation onwards are carried out in a class 300,000 clean area, to guarantee the rutin product quality and stability at the production stage.

Rhamnose—With the natural ingredients extracted from the unique natural plant—fructus aurantii immaturus in China as the raw material, the product is being widely applied worldwide such as the Europe as a natural ingredient of food flavors and cosmetic perfume. Its medicinal value has been developed vigorously recently in the U.S., and its future applications in the field of medicine are worth expecting. The product is made through hydrolytic decomposition →fermentation. The company can produce 100 tons every year.

Radix glycyrrhizae products—They are refined from the natural plant—radix glycyrrhizae, have good effects like anti-inflammation and liver function protection, and are widely applied in pharmaceutical industry, cosmetics industry, and food industry, etc. In the medical aspect, the products are widely applied in anti-inflammatory drugs for external use and drugs for patients with liver disease; the products are also generally applied in cosmetics and shampoo, etc. owing to the anti-inflammatory effect in skin. The products are mainly monoammonium glycyrrhizinate (S/A) and dipotassium glycyrrhizinate, with yearly capacity of 80 tons.

Radix glycyrrhizae products from natural plant have become increasingly popular with the people as they pursue the idea of “returning to nature” in recent years, and the applications thereof have also become increasingly wide. The company invested RMB 2 million to build a multifunctional refining workshop for medical intermediates, etc. in 2004, which is equipped with various centrifuges and box-type double cone dryers, etc. to flexibly deal with the refining production of various lytic enzymes and varieties, and handles and produces 1 ton every day. The residual solvent and purity, etc. of Chinese products handled in the facility through strict and exquisite process are further improved and reach internationally recognized specifications.

All water for production of the company is treated through two-level reverse osmosis membrane, and the entire purified water system achieves full-closed dynamic circulation, to eliminate the danger of microbes breeding in the system. The strict dynamic monitoring is implemented for the detection. The raw water is sent for inspection and qualification every year according to the Chinese drinking water criteria, and the purified water is detected according to requirements of the Chinese Pharmacopoeia every month, with the treated purified water fully complying with quality requirements of the Chinese Pharmacopoeia and Japanese Pharmacopoeia.

The company successively passed Chinese pharmaceutical GMP certification, ISO9901 certification, and KOSHER certification from 2001 and successfully obtained the Accreditation Certificate of Foreign Drug Manufacturer from Japan Ministry of Health, Labour and Welfare in 2006, and its rutin CEP has received the EU EDQM certificate in 2017. The company conducts production in strict accordance with GMP guidelines, and has constructed a comparatively perfect quality management system; it carries out effective quality monitoring of the whole process of procurement, production and sales through hardware and software. The company has introduced various advanced experimental and analytical instruments. It conducts strict quality control according to JP and EP quality standards, etc. and can meet different requirements of customers from all over the world. Continuing to treat market and customers as the focus, guided by provision of first-class products and services, the company will constantly seek for continuous improvement of the quality management system.

In line with the ideas of helping the nature and living in harmony with the environment, the company invested RMB 5 million in 1995 to establish a sewage treatment facility where production and domestic sewage is conducted strict normalized treatment to reach the level I environmental discharge standard of China. The company invested RMB 4 million to construct sewage treatment phase II project in 1998 with the expansion of varieties of the company, and for the continuous operation of the facility, continued to invest RMB 2 million in 2006, to conduct comprehensive maintenance and protection of the entire facility. It successively constructed three sewage tanks in 2016 and 2017, of which the COD value has reached a steady state.

With globalization of environmental issues, the company devoted itself to probing into the environment transformation project of transformation from diesel to natural gas, to guarantee its stable and sustainable development. And the project has been completed and operated since 2008. Its emission concentrations of carbon dioxide, nitric oxide, and sulfur dioxide have been greatly reduced and reached international emission standards upon detection.

Looking into the future, the company will unite, provide customers with better products as always, and continue to innovate and strive to build itself into a global quality manufacturing enterprise.

ALL

ALL Pharma in China

Pharma in China Pharma Experts

Pharma Experts Market News

Market News Products Guide

Products Guide Brand Story

Brand Story

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025