June 12, 2024

Tag:

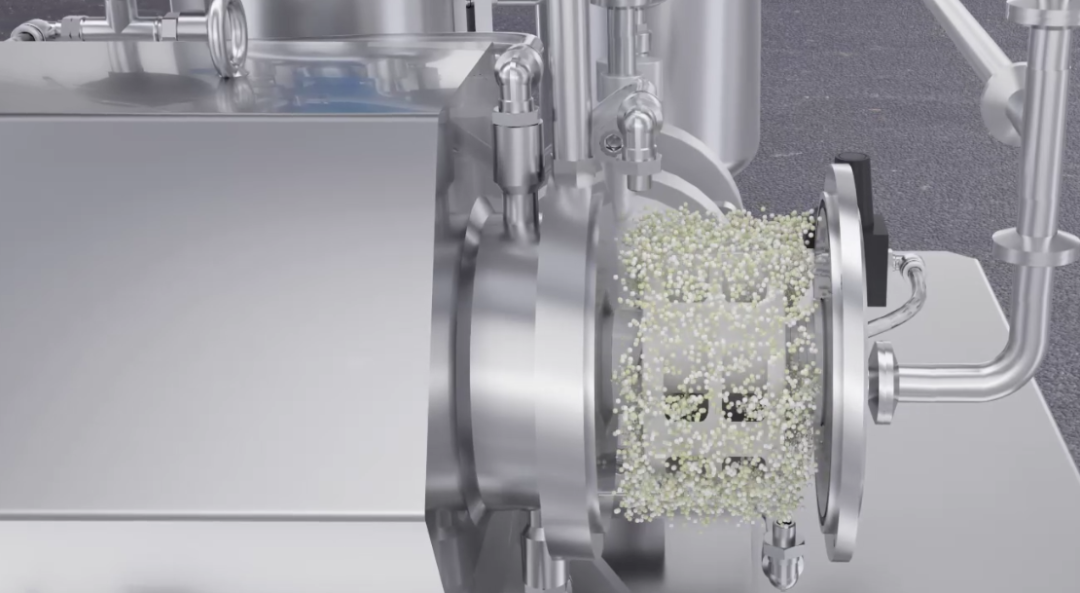

In the field of bead milling technology, wet grinding has always been a critical and complex link.

How to efficiently and accurately control the grinding process, improve grinding efficiency, and reduce material waste has always been a topic that researchers and engineers are constantly exploring.

Recently, Boyee obtained an invention patent certificate for "wet grinding control method". This innovation has injected new vitality into the development of bead milling technology.

During the grinding process, traditional wet bead milling equipment often faces the problem of grinding beads entering the separator channel when they are stationary.

This not only leads to a reduction in the number of grinding beads, affecting grinding efficiency, but is also likely to cause equipment failure due to the grinding beads blocking the channels.

To solve this problem, many researchers have tried to prevent the entry of grinding beads by increasing the length of the separation channel or changing its structure.

However, these methods often lead to complex equipment structures and increased processing difficulty, while also affecting the dynamic balance and separation efficiency of the separator.

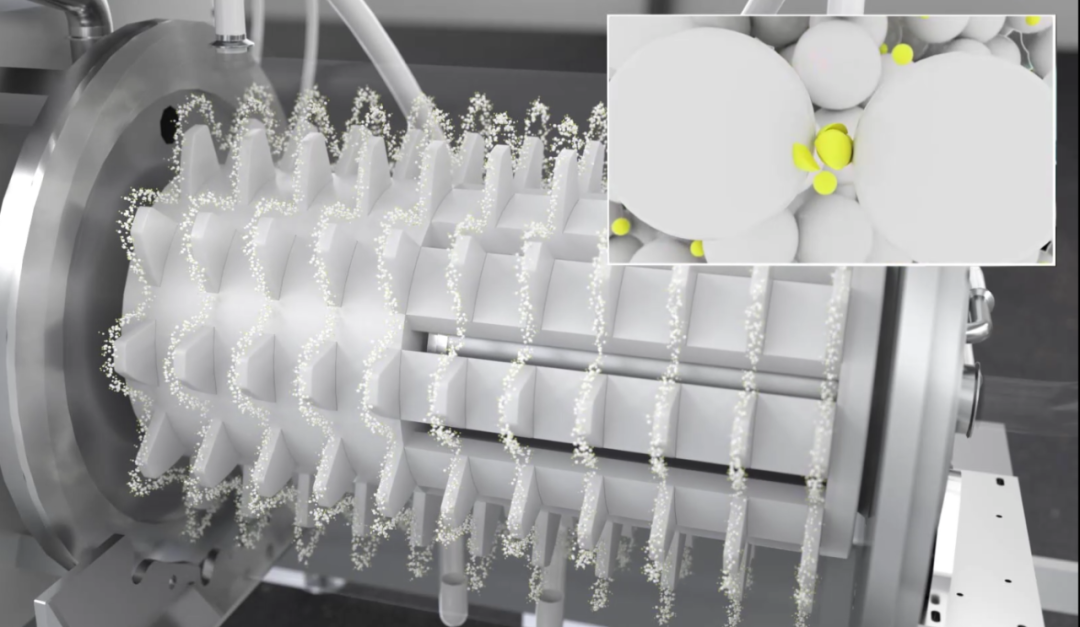

Boyee's new invention provides a new solution from the perspective of control method. The core of this wet grinding control method lies in the fine control of the startup and shutdown steps.

When starting the machine, first ensure that the discharge port switch is in the closed state, then drive the separation device to rotate to the first set speed, and then drive the separation device to rotate to the second set speed.

The switch at the discharge port is opened only when the separator and the separation device reach their respective rated operating speeds. The careful design of this step ensures the stability and efficiency of the grinding process.

When the grinding system stops working, the separation inlet is controlled so that it is located below the plane passing through the center of the rotating shaft.

In this way, even in the shutdown state, the grinding beads will not enter the separation channel through the central through hole, thereby avoiding the problem of the grinding beads being discharged when stationary.

The advantages of this invention lie in its simplicity and efficiency. It does not require any changes to the physical structure of the equipment, but can effectively solve the problem of grinding beads entering the separation channel through precise control methods.

This not only reduces the processing difficulty and cost of the equipment, but also improves the stability and service life of the equipment. At the same time, due to the reduction of grinding bead waste, the grinding efficiency is also greatly improved.

Boyee, as a leader in the field of wet grinding and dispersing, relies on its strong R&D capabilities and unremitting spirit of innovation.

It has won many core invention patents, built a solid technical barrier, and brought important breakthroughs in the field of bead milling technology.

However, Boyee's achievements go far beyond this. In the field of wet grinding and dispersion, the company has also won a number of core invention patents.

These patents not only involve the structure and working principle of the grinding equipment, but also include the optimization of the grinding process, the improvement of the grinding effect and other aspects.

The acquisition of these patents is not only a recognition of Boyee's R&D capabilities, but also an affirmation of its leading position in the industry.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025