July 21, 2022

Tag:

With sustainable development required by most of countries, a new model of evaporator with energy saving, environmental protection and safety have been the direction of future equipment development. At present, coal-fired boilers are gradually shut down, while enterprise operation costs increase rapidly due to the continuous rising of unit steam production cost of natural gas and biomass boilers. At the same time, the wide application of wind and photo voltaic power generation technology have led to the sufficient supply and comparatively lower price of electricity. The traditional evaporation and concentration equipment in the market needs not only heat source for heating, but also cold source for cooling. It has obvious disadvantages of two-way energy consumption, high unit energy cost and high solvent consumption. Because the heat source temperature is high, it is destructive especially to heat sensitive materials. Although the existing MVR evaporating unit has reduced energy consumption in operation to some extent, it has potential dangers in terms of organic solvent recovery due to the contact between flammable and explosive gas solvent and high-speed compressor impeller, and the site installation and maintenance is rather complicated, covering a large area and inconvenient to operate. In view of the current situation of domestic and overseas evaporation and concentration equipment, in order to meet the updating requirements of users, new model of Vacuum low temperature evaporator with characteristics of intelligent, energy-saving, safe and environmental protection has been developed.

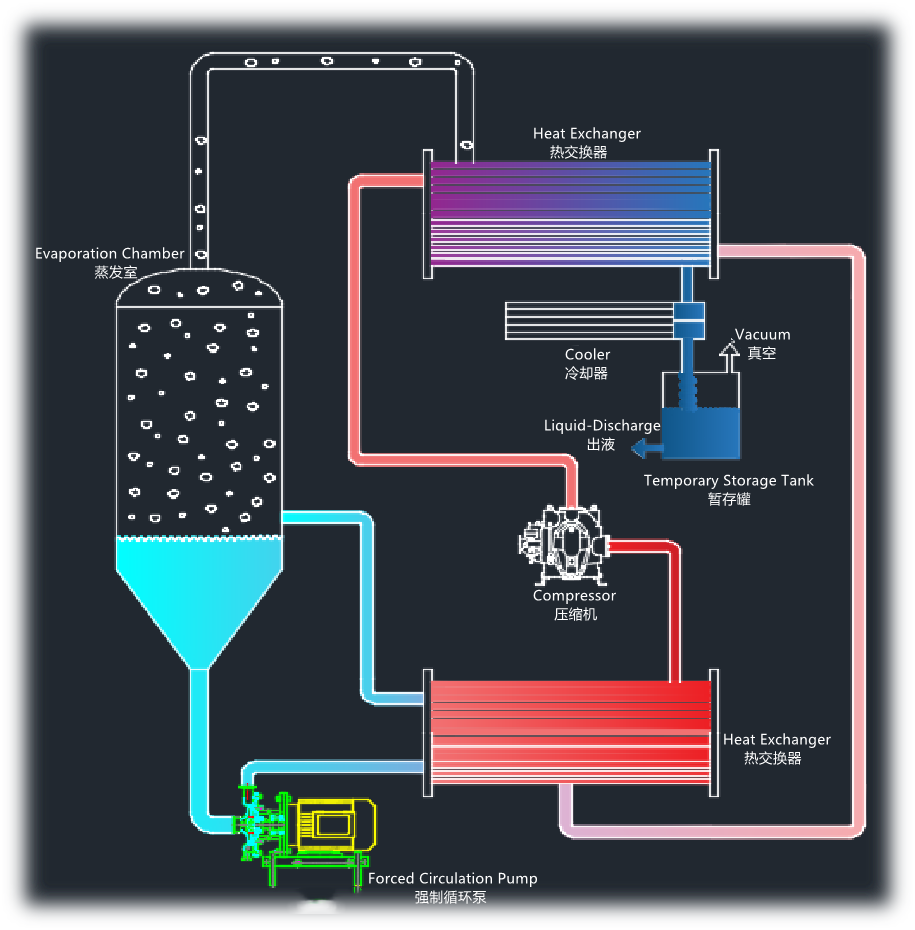

SDR-Single Effect Energy- Saving Evaporator

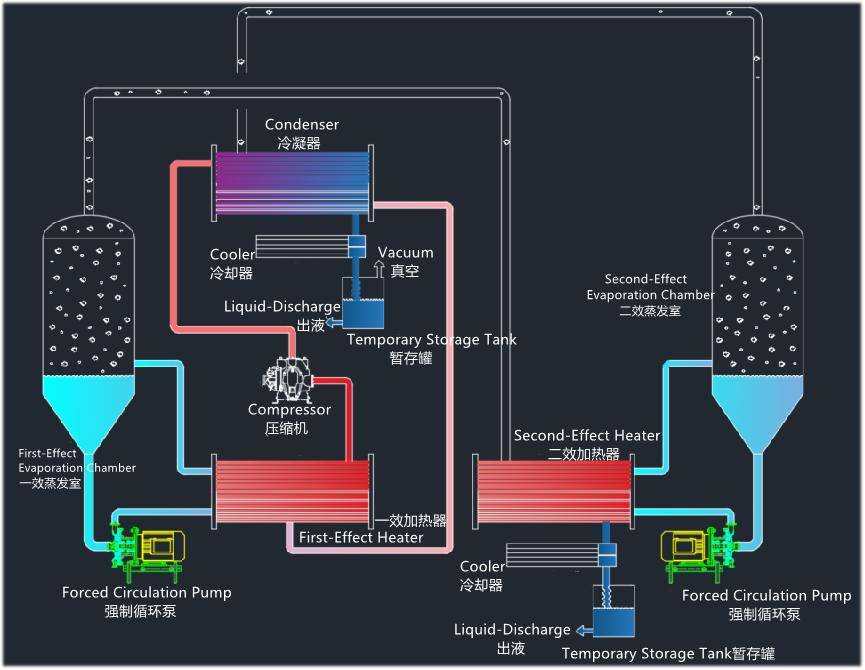

SDR-Double Effect Energy- Saving Evaporator

The equipment is widely used in the dehydration process of pharmaceutical, food, chemical, biological, environmental protection and other industries, and it is more suitable for the evaporation and concentration of organic solvents (mainly used in flammable and explosive category), such as methanol, ethanol, ethyl acetate, acetone, n-hexane solution and other organic solvents; It can also be used for evaporation and concentration of water solution.

Comparison of energy consumption of evaporating 1000L/h solvent concentrator(Moisture Evaporation:1000L/h):

| Evaporator Model | Regular Single-effect evaporator

|

SDR High-efficiency and energy-saving low-temperature evaporator

|

||

| 70% ethanol solution |

Unit Price

|

|||

|

Steam consumption

|

700kg/h | 168 CNY | 30(Preheating material) | / |

| Cooling water | 45T/h | 13.5 CNY | 13T/h | 3.9 CNY |

| Total power(Kw/h) | 5.5Kw | 13.5 CNY | 55 Kw | 38.5 CNY |

| Operating cost

(CNY/1000L) |

185.35 CNY | 42.4 CNY | ||

| Ethanol recovery rate

|

90% | 97% | ||

| Daily operating cost

(2x6h/shift) |

¥2224.2CNY | ¥508.8CNY(840L more ethanol recycle per day) | ||

| Yearly operating cost

(250Days) |

¥556,000CNY | ¥127,000CNY(convert 95% ethanol: 1130,000CNY/Year) | ||

Remark: Steam is ¥240 CNY/ton, cooling water is ¥0.3 CNY /ton, electricity: ¥0.7CNY /kWh, 95% ethanol price: ¥7000CNY /ton.

MINJIE VACUUM BELT DRYER &EVAPORATOR

Leading manufacturer and Exporter of Vacuum Belt Dryer& SDR-Evaporator

Contact: +86 18301902739

Whatsapp link: https://wa.me/8618301902739

Email: globalsales1@shmjjx.com

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025