June 18, 2024

Tag:

In the field of modern energy technology, lithium batteries have become an indispensable energy source for many electronic products, electric vehicles, etc. due to their high energy density, long life and environmental protection.

In the field of modern energy technology, lithium batteries have become an indispensable energy source for many electronic products, electric vehicles, etc. due to their high energy density, long life and environmental protection.

The production process of lithium battery raw materials, especially the grinding technology, plays a vital role in the overall performance of the battery.

Next, we will explore in depth the production process of lithium battery raw materials, and focus on the application and optimization of grinding technology in this process.

01

The importance of grinding technology in the production of lithium battery raw materials

Grinding technology, as one of the core processes in the production of lithium battery raw materials, not only determines the particle size distribution and morphology of the material.

It also directly affects key indicators such as energy density, charge and discharge performance, and cycle stability of lithium batteries.

Therefore, choosing a suitable grinding system and optimizing grinding parameters are crucial to improving the overall performance of lithium batteries.

02

Detailed explanation of lithium battery raw material grinding technology

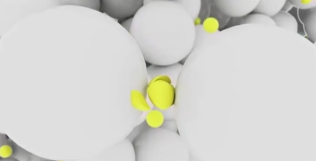

The positive electrode material is the "heart" of the lithium battery. Common positive electrode materials such as LFP need to reach the nano level during the grinding process.

Nano-scale particles can increase the diffusion rate of ions, thereby improving the energy density and charge and discharge performance of lithium batteries.

However, too high a surface area may also lead to increased electrode/electrolyte reactions. Therefore, the particle size distribution needs to be precisely controlled during the grinding process to ensure the optimization of material properties.

The negative electrode material is the "warehouse" that receives lithium ions in lithium batteries. Common negative electrode materials include silicon-based materials.

Through grinding technology, the particle size and morphology of the negative electrode material can be adjusted to improve its lithium storage capacity and cycle stability.

Proper grinding can ensure that the negative electrode material can better contact with the electrolyte during the charging and discharging process, thereby improving the reaction efficiency.

The battery separator is the "gatekeeper" that separates the positive and negative electrodes in lithium batteries, and its performance directly affects the safety and stability of lithium batteries.

During the membrane production process, the ceramic coating is processed through grinding technology to make it more uniform and dense, thereby improving the ion conductivity and mechanical strength of the membrane.

03

Grinding system selection and optimization

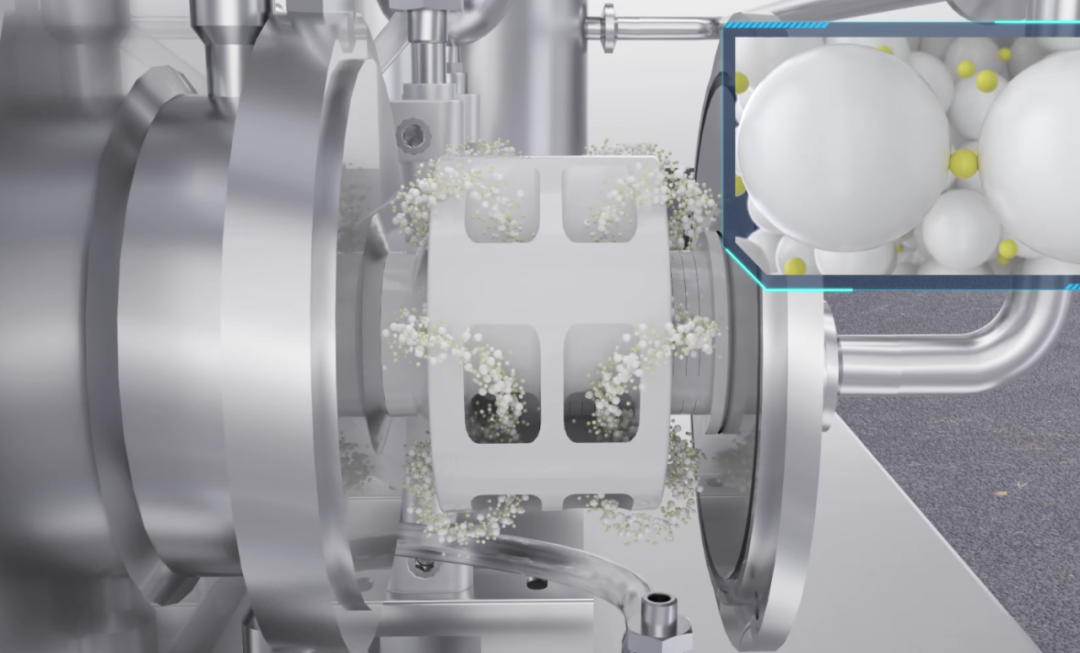

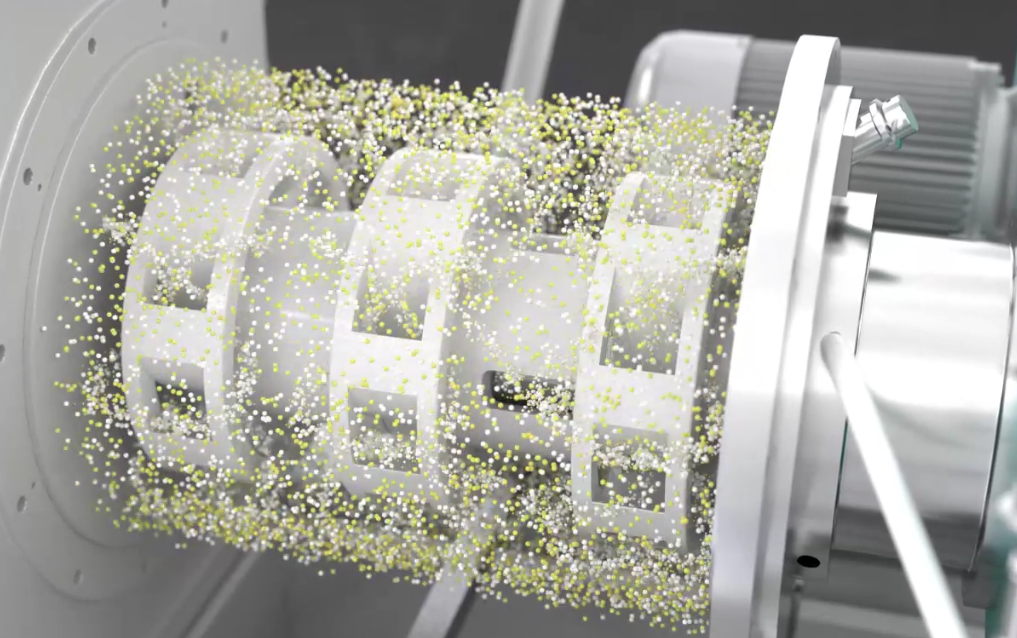

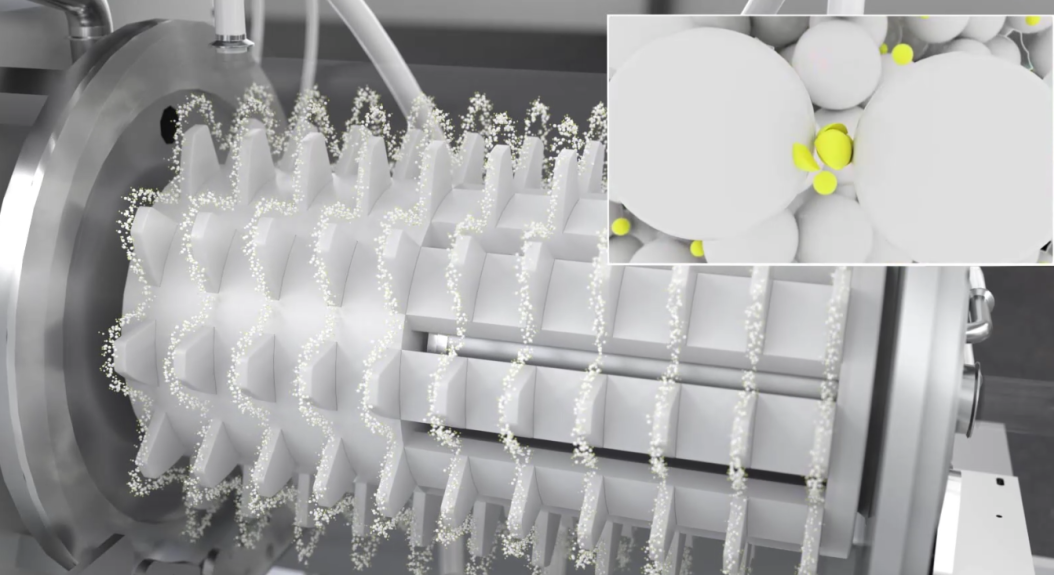

In order to meet the strict requirements on particle size distribution and morphology in the production of lithium battery raw materials, it is necessary to select a suitable grinding system and optimize it.

Boyee's advanced grinding system has become an ideal choice for the production of lithium battery raw materials with its efficient and precise grinding capabilities.

During the grinding process, parameters such as grinding time, grinding media, and grinding speed need to be precisely controlled to ensure that the material achieves the ideal particle size distribution and morphology.

With the continuous expansion of the lithium battery market and the continuous advancement of technology, the role of grinding technology in the production of lithium battery raw materials will become increasingly prominent.

In the future, through continuous technological innovation and optimization, grinding technology will help lithium battery performance achieve new breakthroughs and contribute to the development of modern energy technology.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025