October 28, 2024

Tag:

In modern industrial production, grinding and dispersion of materials are key steps, especially in industries such as new energy battery materials, high-performance coatings, inks, pharmaceutical preparations, semiconductor materials and cosmetics manufacturing, which have strict requirements on the particle size and distribution of materials.

Although traditional grinding technology can achieve material crushing, it is often difficult to avoid the destruction of particle structure. This limitation is unacceptable in many applications.

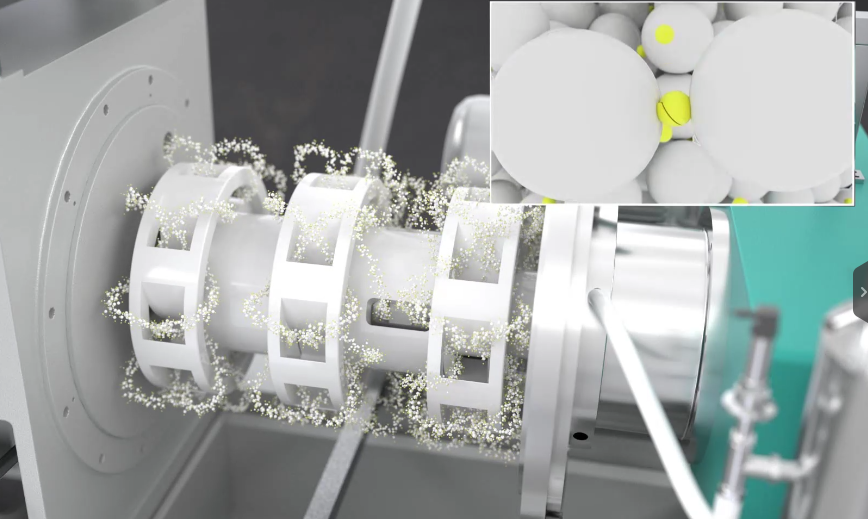

Picture: Schematic diagram of the grinding working area of Boyee bead mill

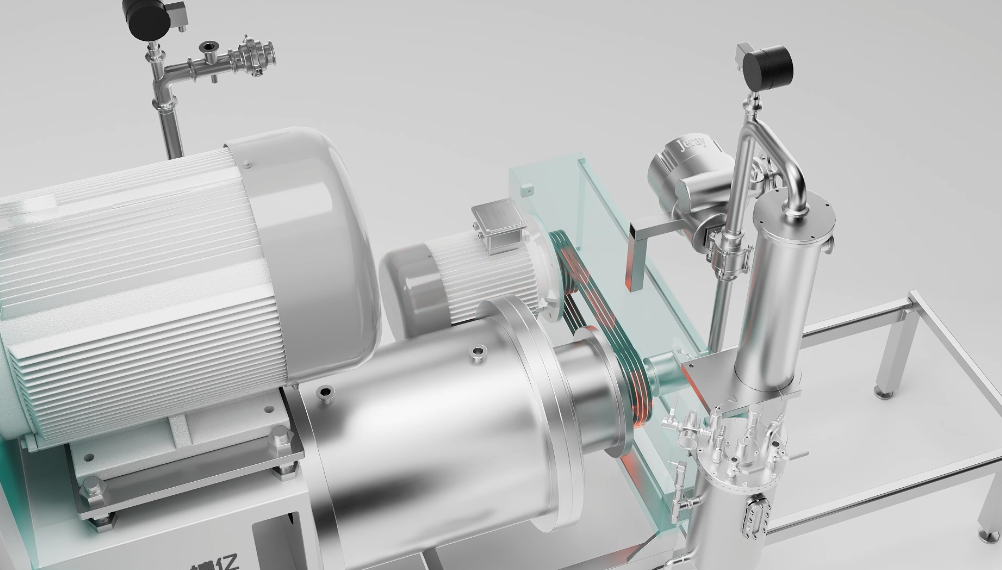

In this context, the flexible grinding and dispersing technology launched by Boyee provides an innovative and efficient solution to this industry problem.

achieves efficient grinding and dispersion of materials without destroying the original structure of particles by precisely controlling the grinding intensity and frequency .

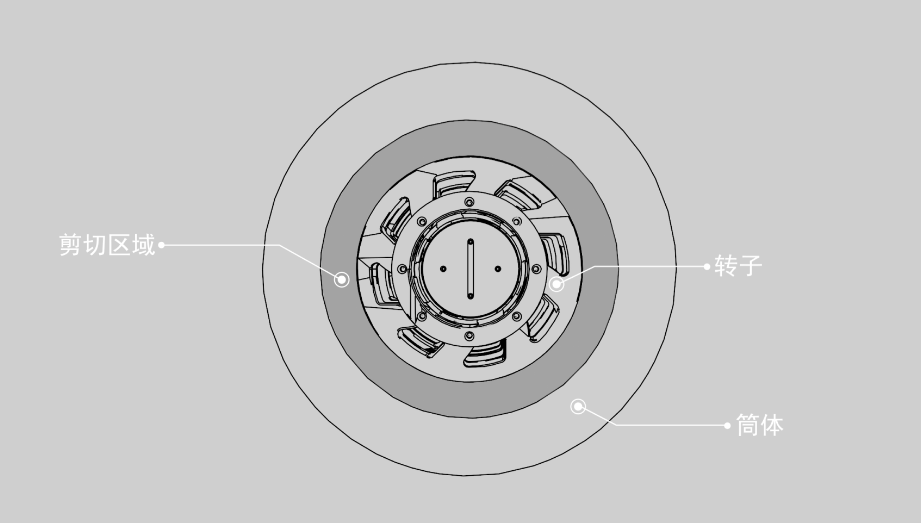

Figure: Schematic diagram of the internal rotor structure of Boyee bead mill

The core of this technology lies in its ability to tailor the particle size distribution based on material characteristics and target.

Flexibly adjust grinding parameters, including the size of grinding media (such as zirconium beads), grinding speed, grinding time, etc. to meet the needs of different industries and application scenarios.

Flexible grinding and dispersing technology has the ability to smoothly switch from low speed to high speed operation, and can cover the complete processing range from slight suppression of particle agglomeration to high-intensity particle crushing.

This technology not only improves grinding efficiency, but also effectively controls the temperature rise of materials during the grinding process and reduces energy consumption by integrating an advanced cooling circulation system.

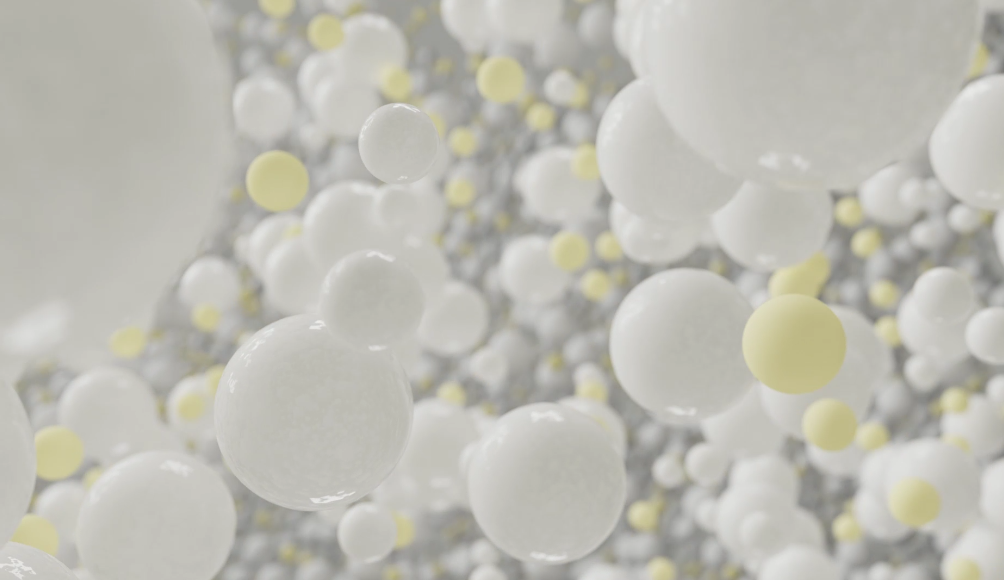

During the grinding process, the size of the zirconium beads has a direct impact on the particle size of the final product.

Small-sized zirconium beads are suitable for low-viscosity slurries and can effectively prevent agglomeration while ensuring the grinding and dispersion effects during the grinding process.

This is because the small size of zirconium beads provides a larger surface area for contact with the material, thereby improving grinding efficiency and dispersion uniformity.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025