July 30, 2024

Tag:

In the coatings industry, with the acceleration of industrialization and the continuous development of intelligent manufacturing technology, more and more companies are beginning to focus on intelligent transformation to improve production efficiency, product quality and environmental performance.

In the coatings industry, with the acceleration of industrialization and the continuous development of intelligent manufacturing technology, more and more companies are beginning to focus on intelligent transformation to improve production efficiency, product quality and environmental performance.

The successful application of Boyee coating's intelligent production line provides a powerful reference for coating companies to build smart factories and realize intelligent operation and maintenance.

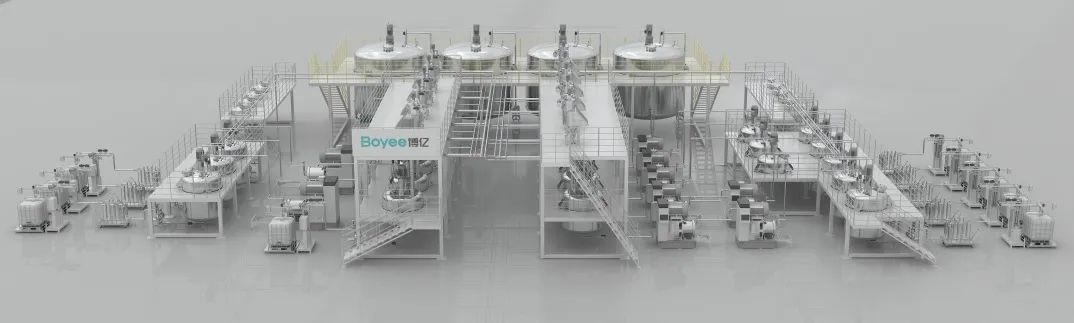

Picture: Boyee coating intelligent production line

Boyee coating intelligent production line integrates a series of key process links such as unpacking and feeding, pneumatic conveying system, emulsifier, grinding equipment, online particle size monitoring system, filter cart, automatic canning system, etc., aiming to create an efficient, stable and environmentally friendly coating production line.

This production line adopts Boyee's core grinding technology, which effectively solves the problems in the traditional grinding process, achieves efficient and stable grinding effects, and improves the performance of coating slurry and printing effects.

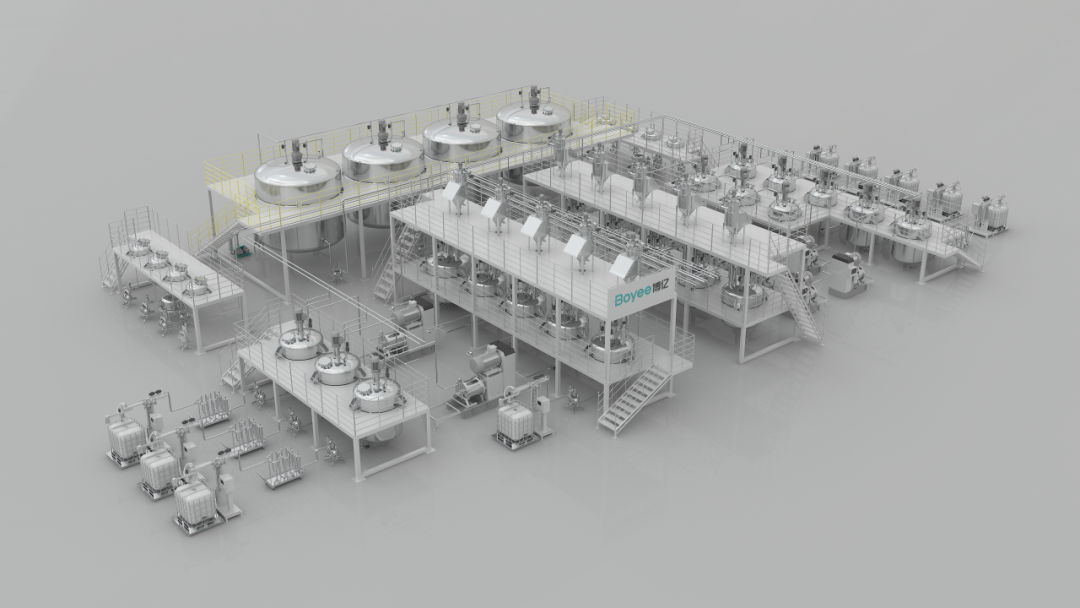

Picture: Boyee coating intelligent production line

To address the problem of diverse product series formulas but low switching efficiency, Boyee coating Smart Factory overall solution provides an automated formula management system.

This system can realize fast and accurate switching of recipes, greatly shortening the production change time and improving production efficiency.

By introducing smart manufacturing supporting equipment and systems, enterprises are able to improve production efficiency, reduce energy consumption and achieve green production.

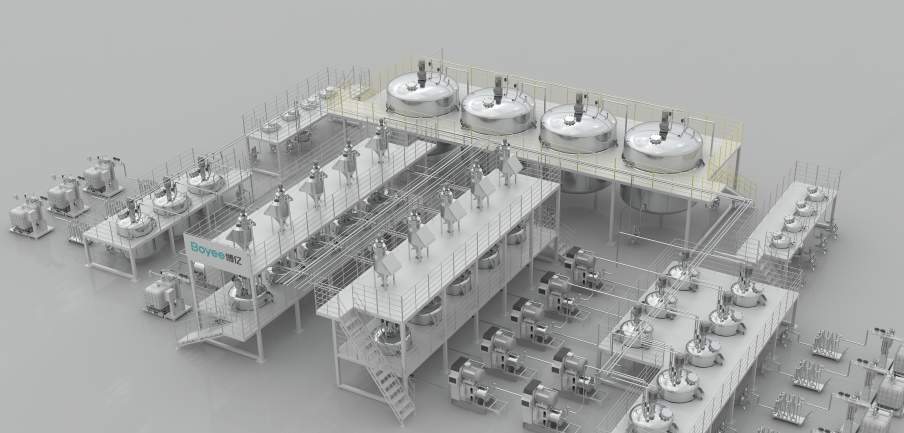

Picture: Boyee coating intelligent production line

The characteristics of Boyee coating intelligent production line are mainly reflected in the following aspects:

1. Optimization of batch material production management: coating production often involves the addition of discrete, flowing and discontinuous materials.

Boyee Solutions controls the process of batch material handling by introducing automation and digital technologies, achieving quality stability for each batch.

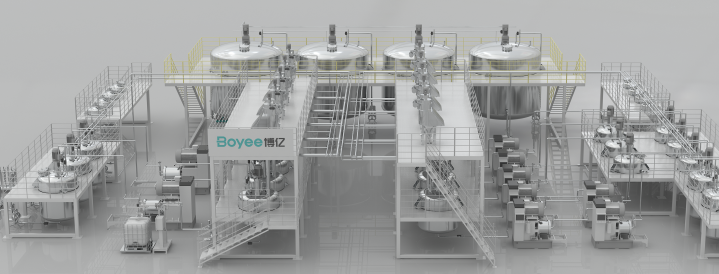

Picture: Grinding process of Boyee coating intelligent production line

2. Enhance production controllability: The traditional coating production process requires many parameters to be adjusted, and often relies on manual experience, judgment and adjustment.

The Boyee solution realizes real-time monitoring and automatic adjustment of production process parameters, enhances production controllability, and reduces production fluctuations and risks caused by human factors.

Picture: Boyee coating intelligent production line

3.Improve production capacity/reduce energy consumption: Automated equipment responds quickly to ensure continued high efficiency of the production line; at the same time, real-time monitoring and adjustment of parameters enable refined management of energy consumption.

For coating companies pursuing technological innovation and sustainable development, Boyee coating intelligent production line is undoubtedly a valuable choice. It will lead the coating industry towards a greener and smarter future.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025