October 22, 2024

Tag:

In recent years, with the vigorous development of the new energy industry, the demand for high-performance battery materials has been growing. Recently, a patented technology for high-solid CNT conductive paste has attracted widespread attention.

In recent years, with the vigorous development of the new energy industry, the demand for high-performance battery materials has been growing. Recently, a patented technology for high-solid CNT conductive paste has attracted widespread attention.

The technology proposes a paste solid content of ≥20% and a carbon tube content of ≥18%, providing a direction for improving the energy density and cycle performance of the battery.

However, in the process of preparing this high-solid content paste, the technical team faced a major challenge: how to ensure a high solid content while effectively controlling the viscosity of the paste to keep it within an appropriate range.

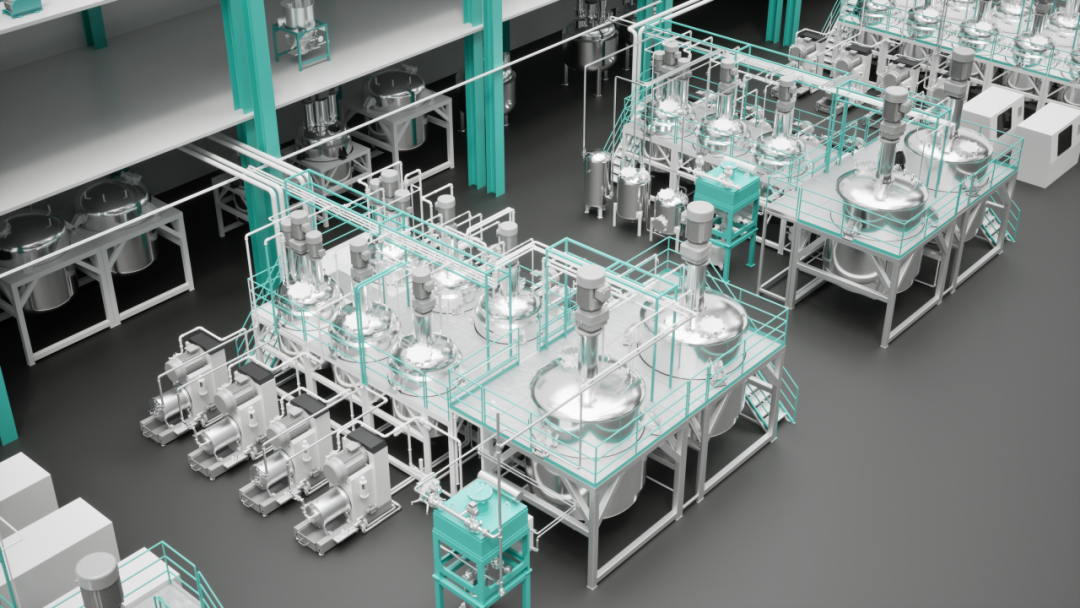

Pictured: Boyee CNT conductive paste solution

After unremitting exploration and optimization by the Boyee team, we finally successfully developed an efficient preparation method.

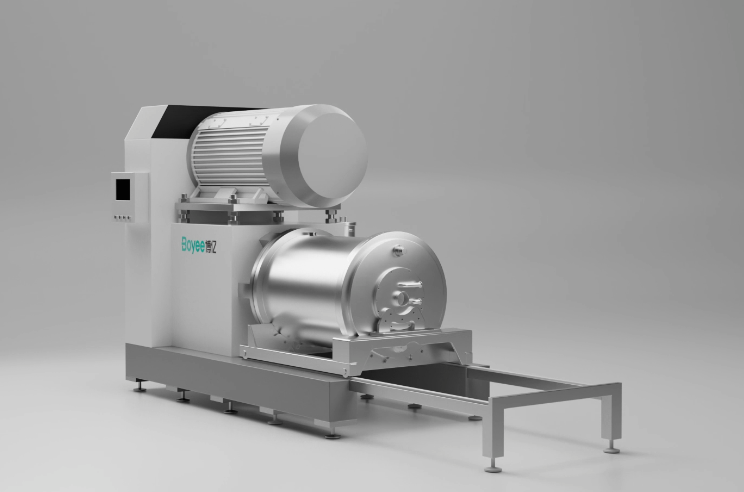

This method utilizes the advanced dispersion technology and solutions of Boyee bead mill to successfully prepare CNT conductive paste with a viscosity of less than 1000mpa.s.

Such a paste can more easily form a uniform and dense coating during the coating process, thereby improving the performance of the battery.

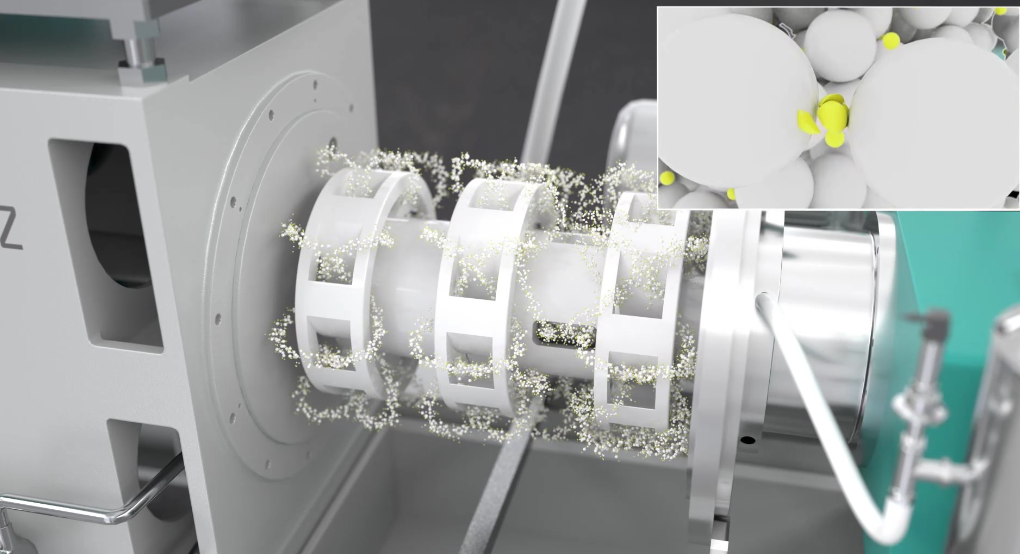

During the preparation process, Boyee bead mill and intelligent production line solutions achieve efficient dispersion of CNT through turbine structure and special grinding media.

During the operation of the bead mill, the CNT are fully sheared and dispersed, effectively avoiding the occurrence of agglomeration.

Through scanning electron microscopy and other microscopic analysis methods, it can be clearly observed that in the CNT conductive paste prepared by Boyee bead mill, the CNT are evenly distributed, there are no obvious agglomerated particles, and the dispersion effect is good.

In the process of preparing SWCNT, chemical vapor deposition (CVD) and bead milling have become two important methods.

CVD is a method of preparing nanomaterials in the gas phase through chemical reactions. When preparing SWCNT, carbon-containing gas (such as methane) and a catalyst are used to react at high temperatures to produce SWCNT.

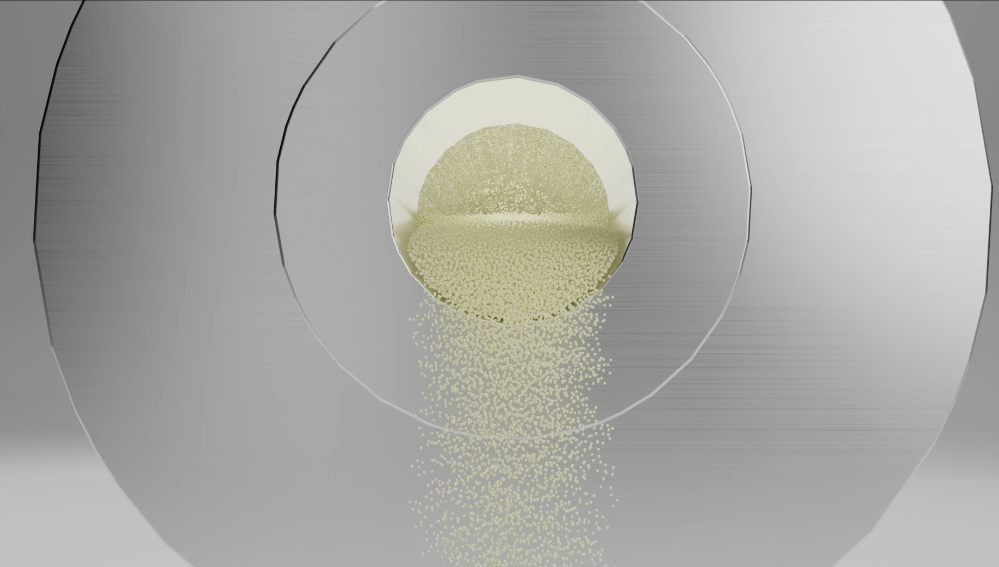

The bead milling method utilizes the high-speed dispersing effect of the bead mill equipment to fully mix and disperse the powder containing graphite or carbon black with the grinding medium to form SWCNT.

The diameter and length of the SWCNT prepared by this method can be controlled by adjusting the grinding time and the material of the grinding medium.

Pictured: Boyee NMM large flow filter type nano bead mill

Compared with multi-walled CNT, SWCNT have the advantages of simple structure and good uniformity.

Under multi-week cycling at 45°C, the internal resistance growth of the soft-pack battery with SWCNT added is significantly lower than that of the battery with other conductive agents added, which indicates that SWCNT can reduce the risk of battery fire and improve the safety performance of the battery.

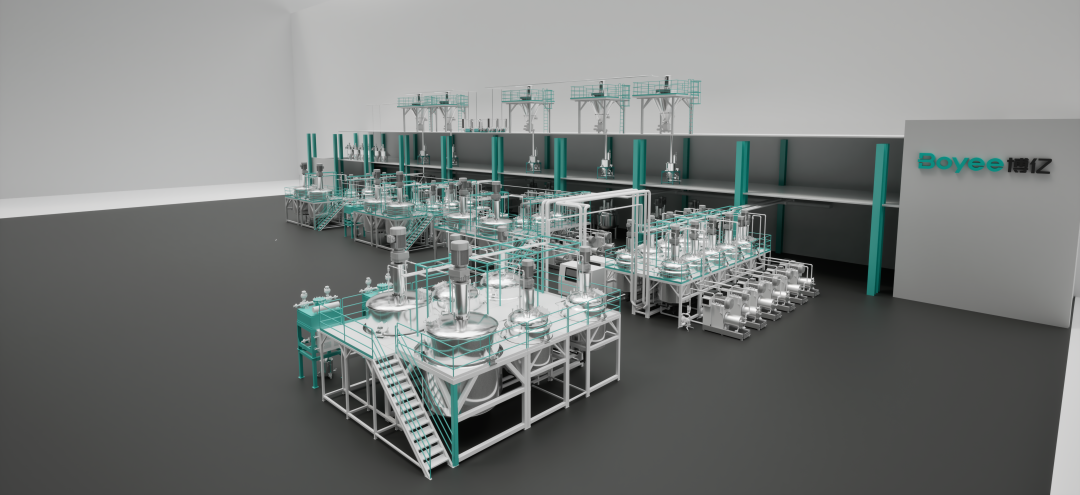

Pictured: Boyee CNT conductive paste solution

Although multi-walled CNT may be slightly inferior to SWCNT in terms of mechanical properties, electrical properties, etc., their production costs are relatively low.

Boyee's CNT conductive paste preparation technology provides more possibilities for the research and development of new energy battery materials.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025