November 14, 2024

Tag:

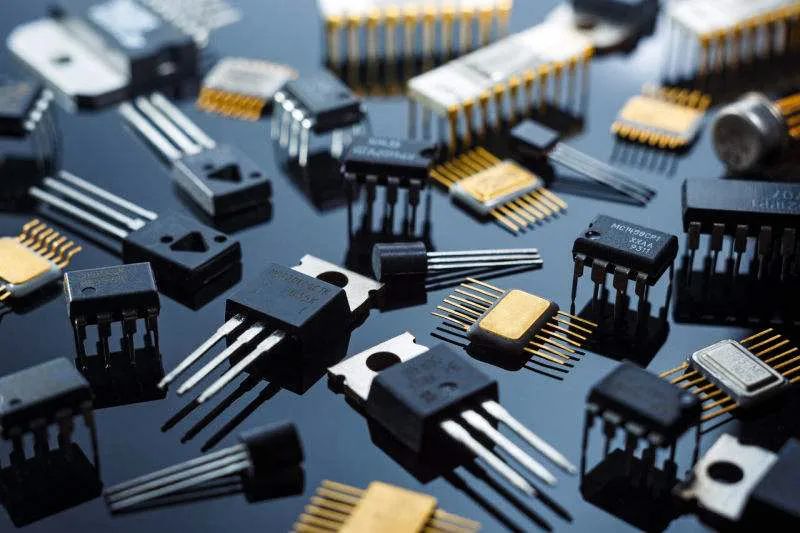

In today's electronic equipment manufacturing field, multilayer ceramic capacitors (MLCCs), as one of the most critical components, are widely used in various electronic products due to their small size, large capacity and stable performance.

From consumer electronics to automotive electronics, from home appliances to communication equipment, MLCC is everywhere, and its importance is self-evident. However, the outstanding performance of MLCC is inseparable from a key factor - the uniformit y and stability of ceramic slurry.

Ceramic slurry is the core material in the MLCC production process, and its quality and stability directly affect the final performance of MLCC.

The unevenness or instability of the slurry will cause problems in the casting and printing process, which will in turn affect the density and stability of the ceramic medium. The particle size and morphology of the ceramic powder are also key factors in determining the performance of MLCC.

Too large a particle size will hinder the trend of thinning and miniaturization, and at the same time affect the product's sintering performance, dielectric constant, dielectric loss, temperature characteristics, capacity and other aspects.

In the process of preparing ceramic slurry, an issue that cannot be ignored is the damage of ceramic powder and the introduction of impurities.

Although traditional dispersion methods can effectively disperse ceramic powders in slurry, the process will inevitably cause wear to the powders and produce impurities that are difficult to remove.

These impurities not only affect the purity of the slurry, but may also change the physical and chemical properties of the powder, such as increasing lattice imperfections or forming an amorphous layer on the surface, which in turn has an adverse effect on subsequent sintering processes.

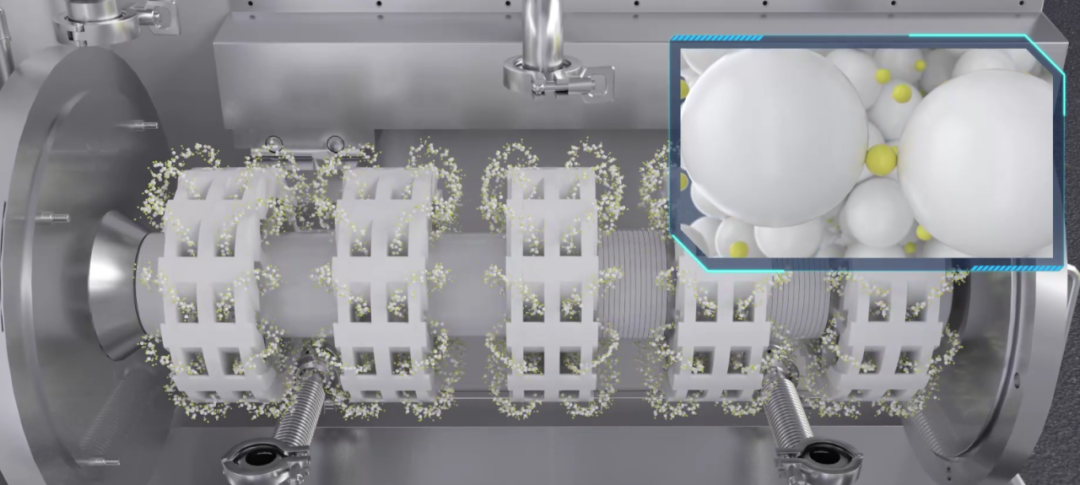

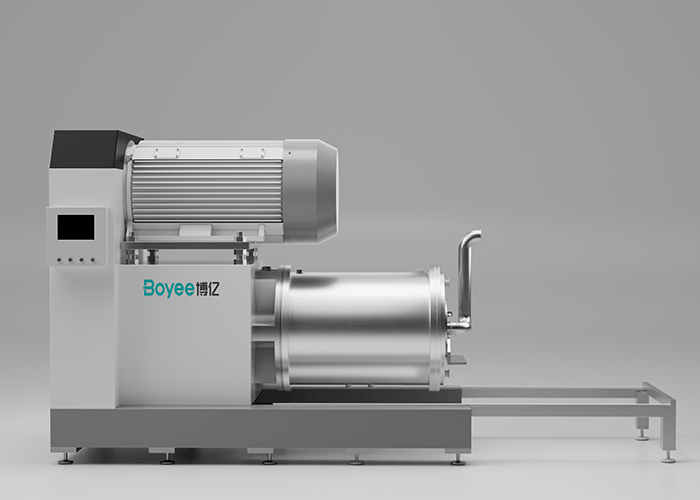

Picture: Schematic diagram of Boyee grinding system

To address the above challenges, Boyee provides a complete set of MLCC ceramic slurry uniformity and stability solutions to ensure the performance and stability of MLCC from the source.

The solution covers packaging and feeding, grinding system, spray drying, kiln sintering, crushing and screening, and finished product packaging.

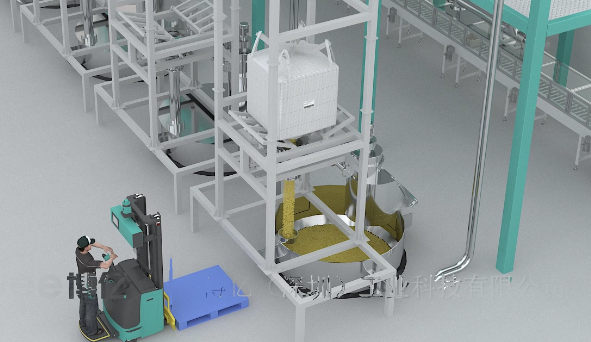

Picture: Schematic diagram of Boyee unpacking and feeding

Advanced automatic unpacking and precise feeding technology are used to ensure the accurate ratio of raw materials.

Through optimized grinding and dispersing technology, Boyee bead mill can effectively disperse ceramic powder evenly in the slurry, effectively avoid agglomeration and precipitation, and minimize the damage of powder.

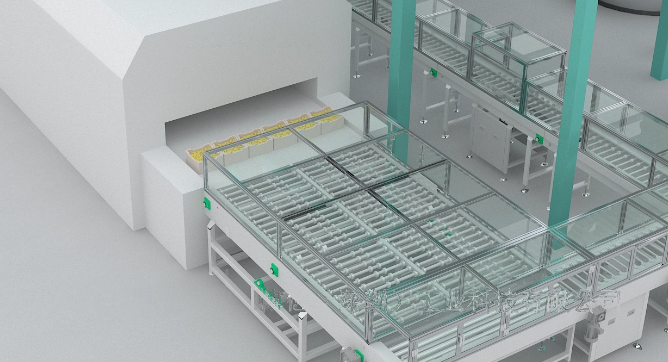

The slurry processed by the bead mill is spray dried to form a uniform ceramic powder, and then undergoes a precisely controlled kiln sintering process to ensure the density of the ceramic medium and good sintering performance.

Picture: Schematic diagram of Boyee kiln sintering system

The sintered ceramic body is finely crushed and sieved to select particles that meet the particle size requirements, and finally the finished products are packaged.

In terms of particle size control, Boyee not only focuses on the monitoring of average particle size and large particle concentration, but also pays more attention to reducing the damage of ceramic powders during the dispersion process.

Pictured: Boyee NMM large flow filter type nano bead mill

Boyee optimizes grinding media, adjusts grinding parameters and introduces advanced protection mechanisms.

Effectively reduce the degree of wear, reduce the generation of impurities, and maintain the original physical and chemical properties of the powder.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight January 2025

Pharma Sources Insight January 2025