September 24, 2024

Tag:

In the pharmaceutical field, core properties of drugs such as solubility, permeability and bioavailability are directly related to their clinical efficacy and market potential.

However, many existing drugs are still limited by problems such as poor solubility, low permeability and rapid metabolism, which greatly restricts their efficient application in clinical practice.

Image source: Visual China

In order to break through these bottlenecks, nanocrystal drug preparation technology came into being and became a key way to improve drug performance.

This article will deeply explore the preparation technology and professional principles of nanocrystalline drugs, as well as Boyee nanocrystalline drug solutions and its technological frontiers.

01

Nanocrystalline drugs: definition, advantages and preparation challenges

Nanocrystalline drugs refer to drug preparations in which the particle size of the drug is reduced to the nanoscale.

This nano-sizing technology can improve the solubility and dissolution rate of poorly soluble drugs, thereby increasing the bioavailability of the drugs.

The advantage of nanocrystalline drugs lies in their small size effect, which can enhance the drug's mucus penetration, endocytosis and transmembrane transport capabilities, thereby improving the drug's oral absorption efficiency.

02

Boyee Nanocrystal Drug Preparation Technology

Boyee provides a complete solution in the field of nanocrystalline drug preparation, using the grinding method as the core technology for nanocrystalline drug preparation.

This method mixes the drug, stabilizer and water in precise proportions and adds them to a closed grinding chamber filled with special grinding media.

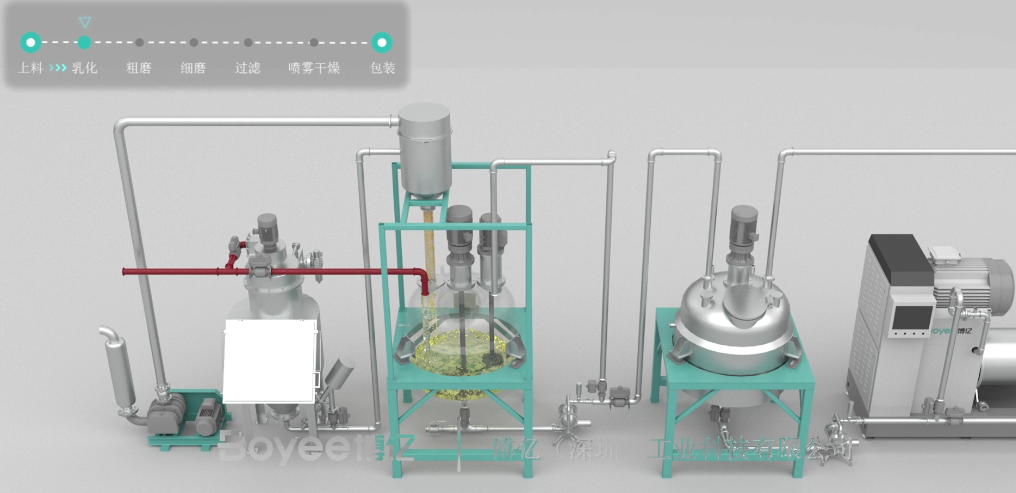

Pictured: Boyee Pharmaceutical's intelligent production line, with solutions covering small bag unpacking station - feeding system - grinding - filtration - spray drying - automatic canning

Through high-speed rotation, strong collision and shear force occur between drug particles, between drug particles and grinding media and the wall of the device.

This effectively refines the drug particles to the nanometer level and produces high-quality nanocrystalline particles.

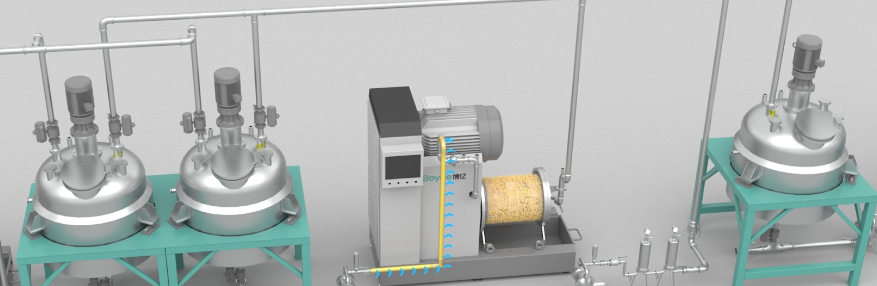

Then, a microfluidizer is used to further homogenize the sand-milled drug to make the particle size of the drug nanocrystals more uniform, reduce the presence of large particles, and improve the stability and bioavailability of the drug.

Pictured: Noze Microfluidizer

At the same time, the combined use of these two devices can also precisely control the particle size of nanocrystals according to different drug requirements to achieve the best therapeutic effect.

For example, in the preparation of nanocrystalline preparations of poorly soluble drugs, this combined application can effectively improve the solubility and bioavailability of the drugs.

The advantages of this technology are simple preparation process, strong operability, stable process, and it is suitable for the preparation of nanocrystals of a variety of poorly soluble drugs.

By precisely controlling grinding parameters such as rotation speed, time, temperature, etc., the size of drug particles can be precisely controlled to meet the needs of different drugs.

03

Technological Frontiers and Future Prospects

With the continuous development of nanotechnology, the technology for preparing nanocrystal drugs is also constantly innovating and improving.

On the one hand, with the in-depth study of the biological effects of nanomaterials and the mechanisms of drug action, it is expected that more nanocrystal drugs with excellent performance and clinical application value will be developed.

On the other hand, with the continuous maturity of preparation technology and the improvement of intelligence level, the preparation of nanocrystalline drugs will be more efficient, environmentally friendly and controllable.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

+86 15021993094

Follow Us:

Pharma Sources Insight July 2025

Pharma Sources Insight July 2025