May 28, 2024

Tag:

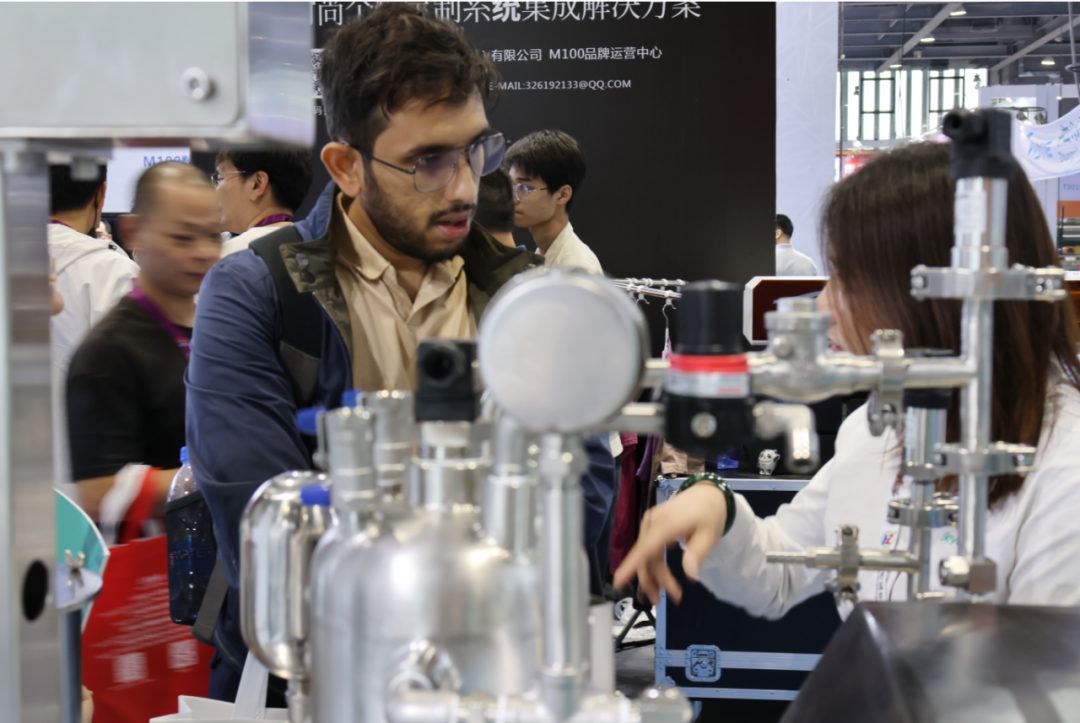

At the 19th International Textile, Garment and Printing Industry Expo held grandly at the Poly World Trade Expo Center in Pazhou, Guangzhou from May 20 to 22, 2024, Boyee attracted much attention with its cutting-edge digital inkjet intelligent production line.

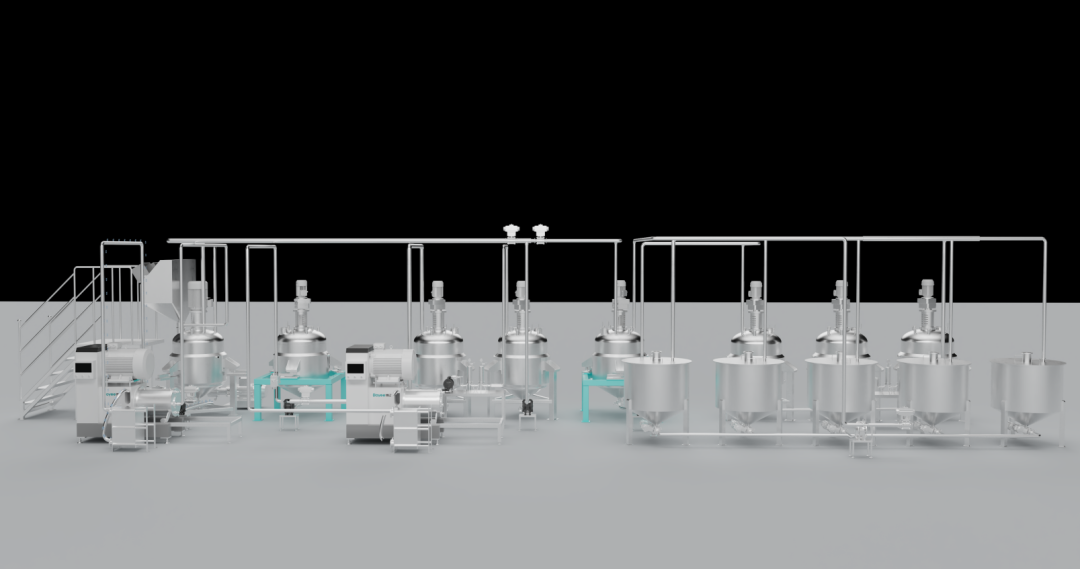

The production line integrates a series of key process links including feeding system, dispersion tank, grinding equipment, online particle size monitoring system, filter, finished product tank, etc.

It also proposes effective solutions to the problems and difficulties in the current digital inkjet production method.

Pictured: Boyee digital inkjet intelligent production line

Pictured: Boyee digital inkjet intelligent production line

Digital inkjet production faces many challenges in the textile and garment industry. The difficulty of ink grinding is particularly prominent. Traditional grinding equipment often has problems such as uneven material dispersion, long grinding time and complex process.

This not only affects production efficiency, but also restricts the improvement of ink performance.

Issues such as cutting piece positioning, pre- and post-processing processes, and ink performance stability in the digital printing process also need to be urgently addressed.

picture

picture

The emergence of Boyee digital inkjet intelligent production line is a powerful response to these problems.

Its intelligent production line system has been carefully designed and optimized in every link from loading to finished cans to ensure the stability and efficiency of ink production.

The feeding system is equipped with high-precision weighing sensors and automatic control systems, which can monitor the weight of materials in real time to ensure that each raw material is accurately dosed according to the preset formula ratio.

In particular, the dispersion tank is equipped with a special design structure, which can deeply disperse the ink, make the particles more evenly distributed in the solvent, and effectively prevent the precipitation and agglomeration of particles.

It improves the fluidity and stability of the ink and optimizes the ink performance during the printing process, making the printed patterns clearer and the colors more vivid.

The digital inkjet intelligent production line also solves the problems in the traditional grinding process by introducing Boyee's core grinding technology and filters.

It can grind ink efficiently and stably, making the ink color purer and improving the performance, thus ensuring the smoothness of inkjet and printing effect.

During the grinding stage, an online particle size detector is equipped to realize automatic sampling and real-time online analysis. It can quickly analyze the particle size of the samples and output the analysis results immediately.

The online particle size detector also has the function of data recording and processing. It can record the particle size analysis results at each time point and generate corresponding data reports.

picture

picture

At the same time, the production line is also equipped with an intelligent control system to achieve comprehensive monitoring and intelligent control of the production process, making production management efficient and visual.

At the 19th Guangzhou International Textile, Garment and Printing Industry Expo, the production line system exhibited by Boyee undoubtedly became the focus of the industry, leading the textile and garment industry to develop in a more intelligent and efficient direction.

Contact Us

Tel: (+86) 400 610 1188

WhatsApp/Telegram/Wechat: +86 13621645194

Follow Us:

Pharma Sources Insight June 2024: Globalization on the Go

Pharma Sources Insight June 2024: Globalization on the Go