|

Shanghai Yuking New Material Technology Co., Ltd..

|

A white powder, odorless or with a slightly characteristic odor. It is highly hygroscopic and soluble in water, ethanol, dichloromethane and many other organic solvents. The liquid form is generally colorless and viscous. Application: Hair Styling Products: In hair sprays, setting lotions and mousses, it is used as a film-former, thickening agent and setting agent. Skin Care Products: In facial masks, it is used as a film-former.

Company Profile

Yuking Technologies is a high-tech enterprise featuring water-soluble polymers with global vision, core competitiveness and industry discourse right.

The company was founded in 2005 with headquarters and R&D center located in Shanghai Zhangjiang International Medical Zone and its pilot &manufacturing bases respectively located in Shanghai Lingang New Area and High-tech district in Hubei Xiangyang.

Our factory has passed the ISO 9001 quality management system, ISO 14001 environmental management system, EXCiPACT, CEP, HALAL, KOSHER certifications and the US FDA registration(DMF), and has obtained the relelvant Drug Manufacturing License.

Yuang Technology will adhere to the business philosophy of "meeting customer needs,pursuing excellent quality,building an excellent team, fulfilling social responsibility",stick to scientific and technological innovation, and continue to

provide customers with quality products and services.

Our Team

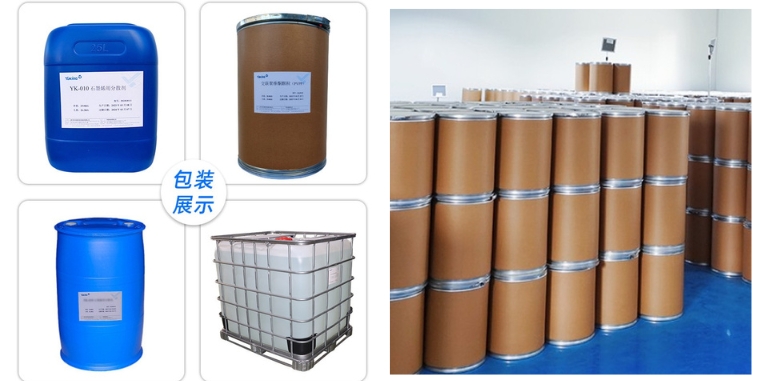

Packaging & Shipping

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

|

Send Inquiry

|

Pharma Sources Insight July 2025

Pharma Sources Insight July 2025